Production process of shrimproe soy sauce

A production process and technology for shrimp seeds, applied in application, food preparation, food science and other directions, can solve the problems of unreliable products and immature processes, achieve a reasonable and complete production process, ensure high quality and stability, and achieve The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

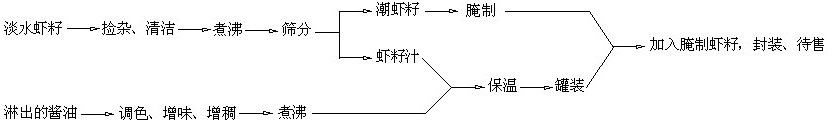

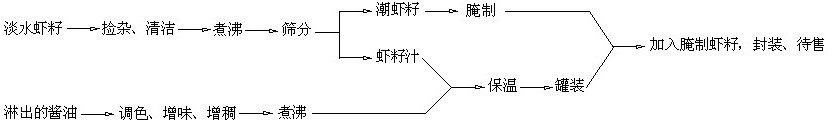

Image

Examples

Embodiment Construction

[0020] A kind of production technology method of shrimp roe soy sauce, comprises the following steps:

[0021] 1) Select high-quality shrimp roe produced from freshwater lakes, rivers, rivers, and ponds to remove impurities;

[0022] 2) Add spices to the cleaned shrimp roe, boil with 4-12 times the weight of shrimp roe in water or salt water or poured out soy sauce, and the time is controlled within 30-120 minutes;

[0023] 3) Separate the boiled shrimp roe with water or salt water or leached soy sauce, and store the separated tide shrimp roe and shrimp roe juice separately;

[0024] 4) Soak shrimp roe in water or salt water or dripped soy sauce with spices and preservatives to make marinated shrimp roe. The time for soaking and marinating is 2-7 days.

[0025] 5) Extract the leached soy sauce, adjust the color, add flavor enhancers, preservatives, thickeners and white sugar;

[0026] 6) Heat the prepared soy sauce in step 5 to boiling, remove foam, add shrimp roe juice, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com