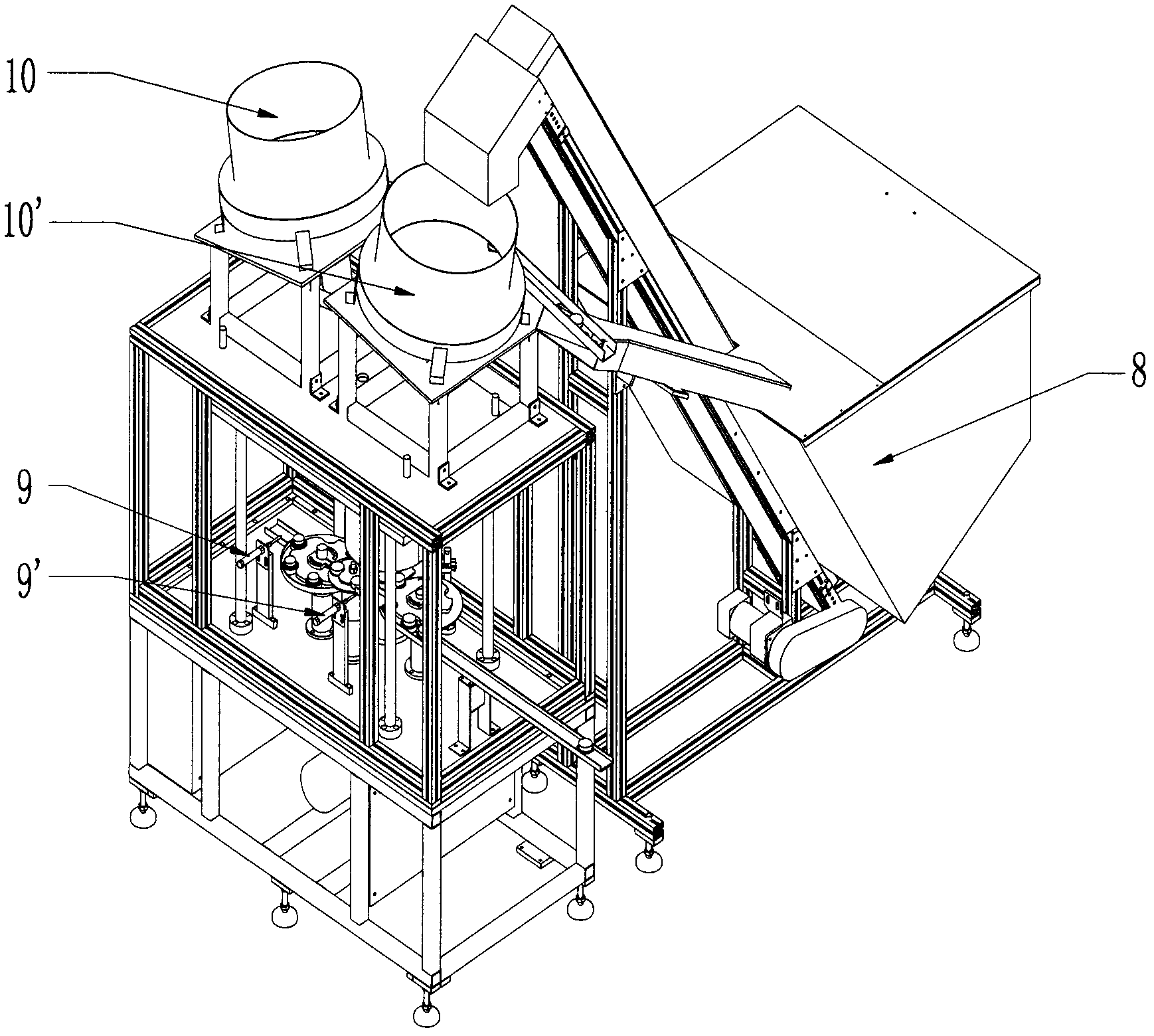

High-speed cap closing machine

A high-speed, cap-arranging machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of limited bottle cap production efficiency improvement space, time consumption, high cost, saving production cycle and maximizing production efficiency , the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

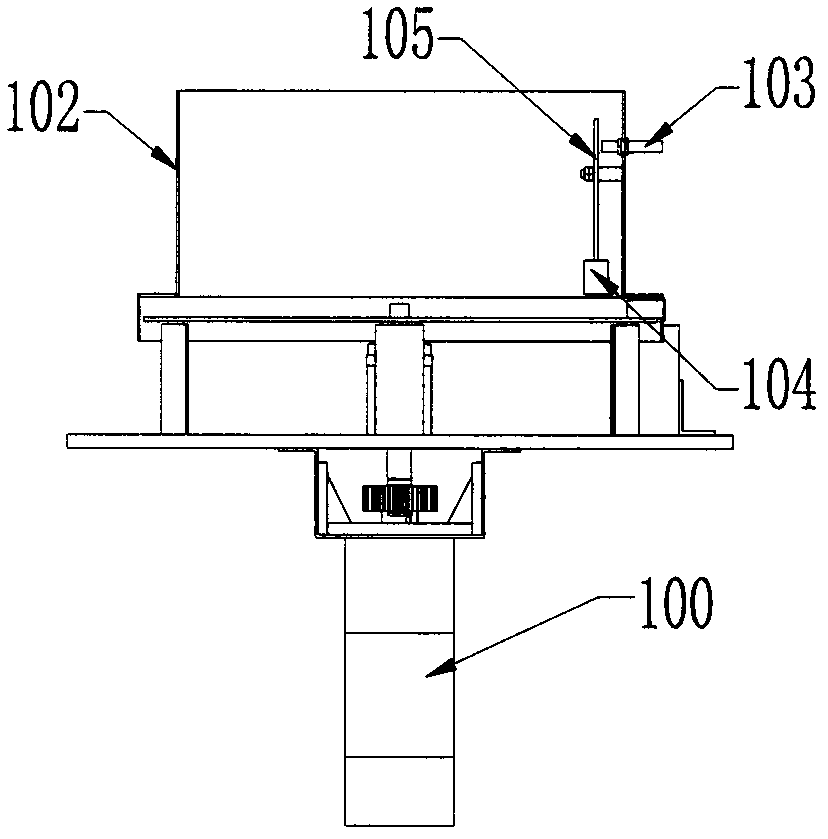

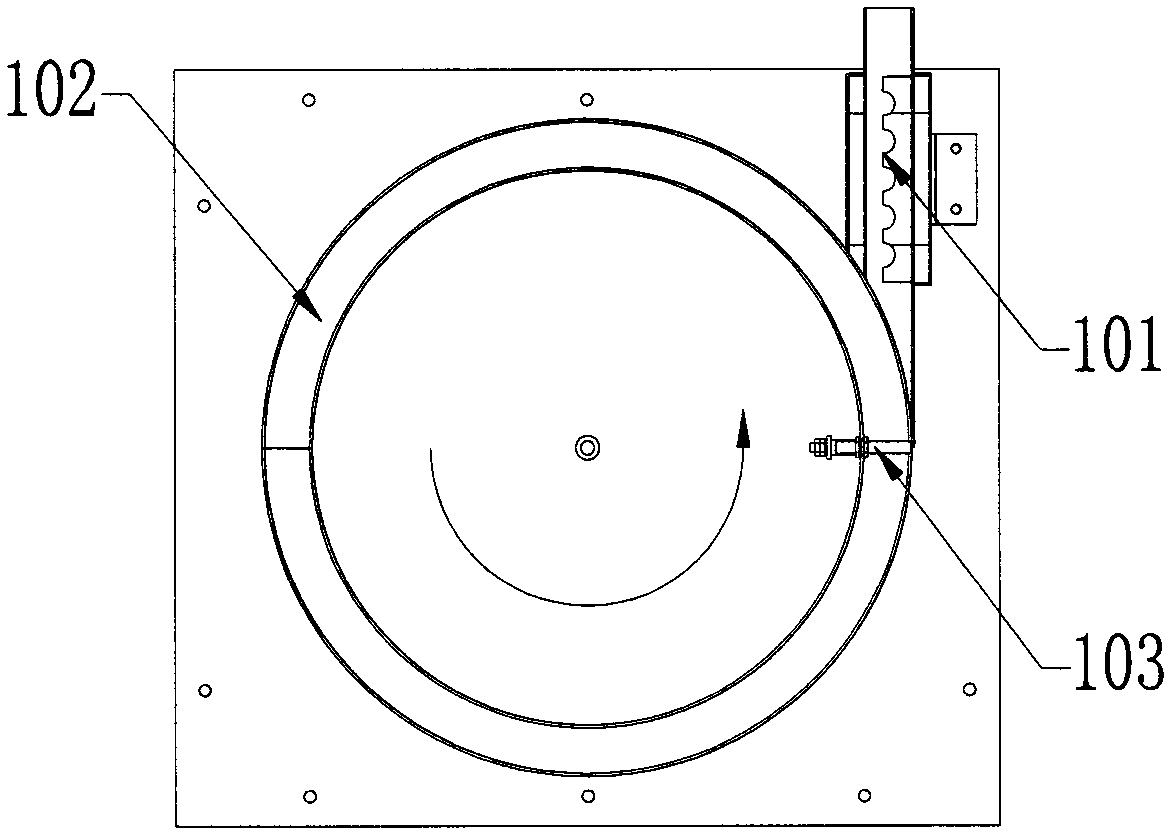

[0032] like Figure 5 and Image 6 The high-speed capping machine includes a main shaft system 1 and a planetary system, the main shaft system 1 includes a first star wheel 112 for continuous feeding and discharging on the main shaft 110, and the planetary system is fixedly connected to the first star wheel 112 above and coaxial with the main shaft 110, the central axis of the planetary assembly 115 in the planetary system corresponds to the central axis of the radial recess on the first star wheel 112, and the planetary assembly 115 moves according to a fixed track , At the lower end of the planetary assembly 115, an intermittent suction head 137' is set.

[0033] Specifically, the first star wheel 112 is fixed on the main shaft 110, and on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap