Inductive scraper

An inductive and scraper technology, which is applied in the direction of rotary printing machines, printing machines, printing machines, etc., can solve the problem of unconfirmed solder paste coating length and distance, waste of mechanical arm power and working time, and inability to clearly understand whether the amount of solder paste is used Meet the requirements and other issues to achieve the effect of facilitating follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

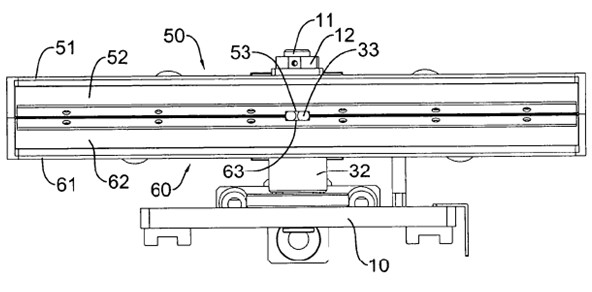

[0009] Such as figure 1 Shown, a kind of inductive scraper comprises scraper assembly 50, scraper assembly 60, scraper assembly 50, and scraper assembly 60 comprises a frame plate 51, frame plate 61 and is located at frame plate 51, scraper blade 52 on frame plate 61, The scraper blade 62, the scraper assembly 50, the scraper assembly 60 is relatively arranged on the device body with its frame plate 51 and frame plate 61, and the detection channel 53 and the detection channel 63 are arranged between the scraper assembly 50 and the scraper assembly 60; 33 is set in the device body and is located above the scraper assembly 50 and the scraper assembly 60, and is used to detect the amount of solder paste through the detection channel 53 and the detection channel 63 between the scraper assembly 50 and the scraper assembly 60 For function measurement, the device body has a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com