Method for removing aluminum by neutralizing sodium chromate alkali solution

A technology of sodium chromate and alkaline solution, which is applied in the field of chromium salts, can solve problems such as the useless value of aluminum hydroxide aluminum sludge, the loss of sodium chromate in aluminum hydroxide aluminum sludge, and the addition of chromium removal processes, etc., and achieves easy equipment transformation , Simple process, cost-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

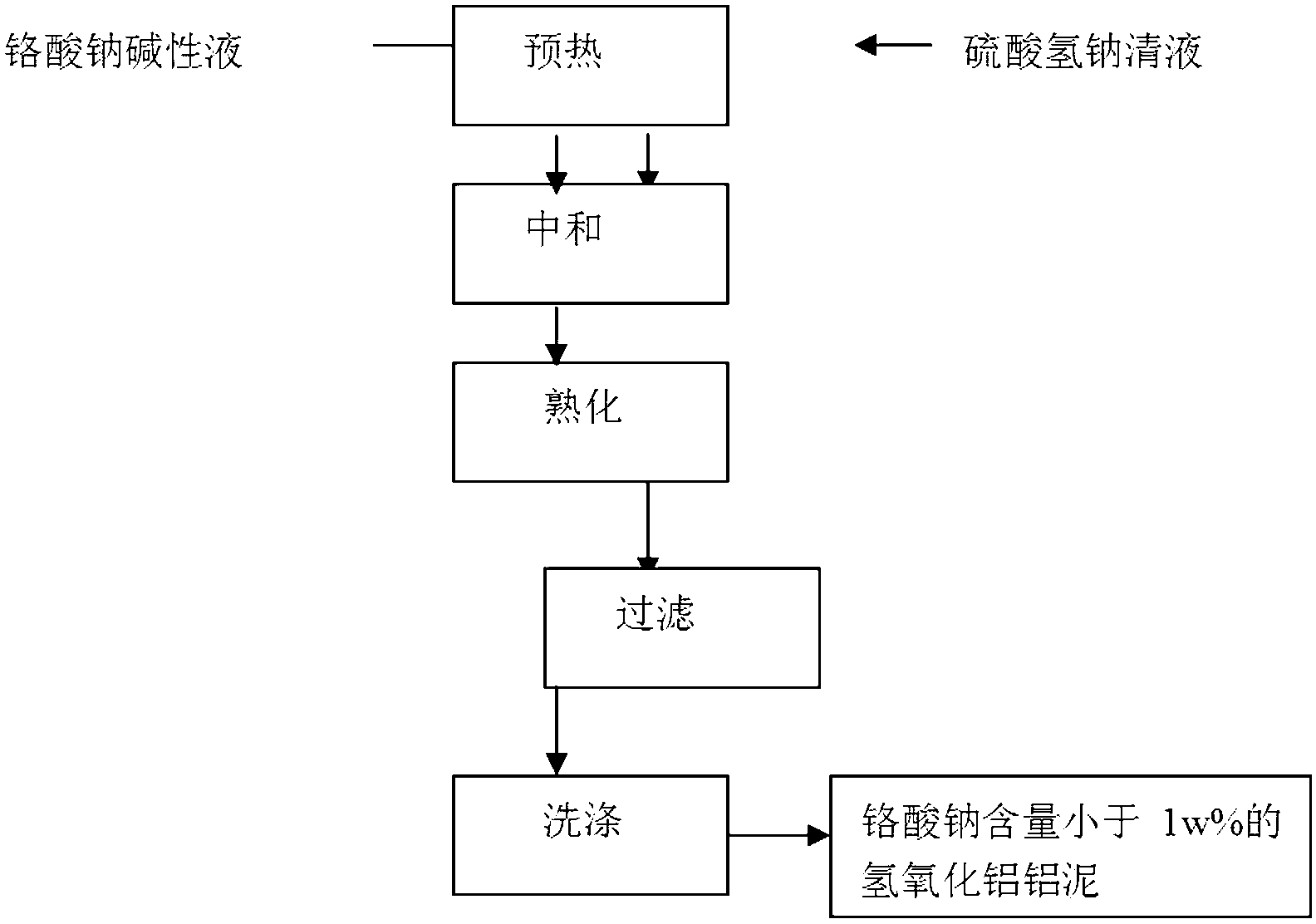

Method used

Image

Examples

Embodiment 1

[0028] (1) Preheating

[0029] Dilute the chromic anhydride by-product solid sodium bisulfate with water, filter the gained sodium bisulfate clear liquid (H 2 SO 4 : 280g / L, Na 2 Cr 2 o 7 .2H 2 O: 46g / L), take 1.7m3 sodium bisulfate clear liquid, preheat to 80°C; take 20m3 sodium chromate alkaline solution (Na 2 CrO 4 : 200g / L, Na 2 CO 3 :15g / L, Al 2 o 3 10g / L), preheat to 80°C;

[0030] (2) Neutralization

[0031] Turn on the 25m3 reaction tank to stir, and the speed is controlled at 50r / min. The sodium chromate alkaline solution flows into the reaction tank at the flow rate of 20m3 / h and the sodium bisulfate clear liquid at the flow rate of 1.7m3 / h. The pH of the sexual fluid is 6.5;

[0032] (3) ripening

[0033] Heat the reaction slurry in step (2) with a pH value of 6.5 to 92°C, and after heat preservation and aging for 1 hour, open the discharge valve and pump it to the plate and frame filter. A volume of 5m3 matured slurry;

[0034] (4) filter

[0035...

Embodiment 2

[0039] (1) Preheating

[0040] Take 1.6m3 sodium bisulfate clear solution (H 2 SO 4 : 260g / L, Na 2 Cr 2 o 7 .2H 2 O: 40g / L), preheat to 90°C; take 11.2m3 sodium chromate alkaline solution (Na 2 CrO 4 : 250g / L, Na 2 CO 3 :25g / L, Al 2 o 3 15g / L), preheat to 90°C;

[0041] (2) Neutralization

[0042] Turn on the 15m3 reaction tank to stir, the speed is controlled at 80r / min, the flow rate of sodium chromate alkaline solution is 11.2m3 / h, and the flow rate of sodium bisulfate clear liquid is 1.6m3 / h. The pH value of the neutral solution is 7.5;

[0043] (3) ripening

[0044] Heat the reaction slurry in step (2) with a pH value of 7.5 to 92°C, and after heat preservation and aging for 1 hour, open the discharge valve and pump it to the plate and frame filter. A mature slurry with a volume of 3.75m3;

[0045] (4) filter

[0046]The 9.05m3 slurry discharged from the reaction tank in step (3) is filtered through a plate and frame filter;

[0047] (5) washing

[00...

Embodiment 3

[0050] (1) Preheating

[0051] Take 1.7m3 of sodium bisulfate clear solution (H 2 SO 4 : 300g / L, Na 2 Cr 2 o 7 .2H 2 O: 42g / L), preheat to 85°C; take 11m3 sodium chromate alkaline solution (Na 2 CrO 4 : 300g / L, Na 2 CO 3 :30g / L, Al 2 o 3 20g / L), preheat to 85°C;

[0052] (2) Neutralization

[0053] Turn on the 15m3 reaction tank to stir, the speed is controlled at 100r / min, the flow rate of sodium chromate alkaline solution is 11m3 / h, and the flow rate of sodium bisulfate clear liquid is 1.7m3 / h. The pH of the sexual fluid is 8;

[0054] (3) ripening

[0055] Heat the sodium chromate neutral slurry containing aluminum hydroxide that has been neutralized to a pH value of 8 to 95°C, keep it warm for 1.5 hours, open the discharge valve, and pump it to the plate and frame filter. Reservation in the reaction tank accounted for 3m3 of the reaction tank volume matured slurry;

[0056] (4) filter

[0057] The 9.05m3 slurry discharged from the reaction tank in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com