Built-in type elbow desulfurization spray gun

A desulfurization spray gun, built-in technology, applied in the field of molten iron desulfurization treatment device, can solve the problems of low degree of stability between refractory material and gun body skeleton, mechanical deformation of gun body skeleton, failure of refractory material layer, etc. Long life and the effect of eliminating the dead angle of injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

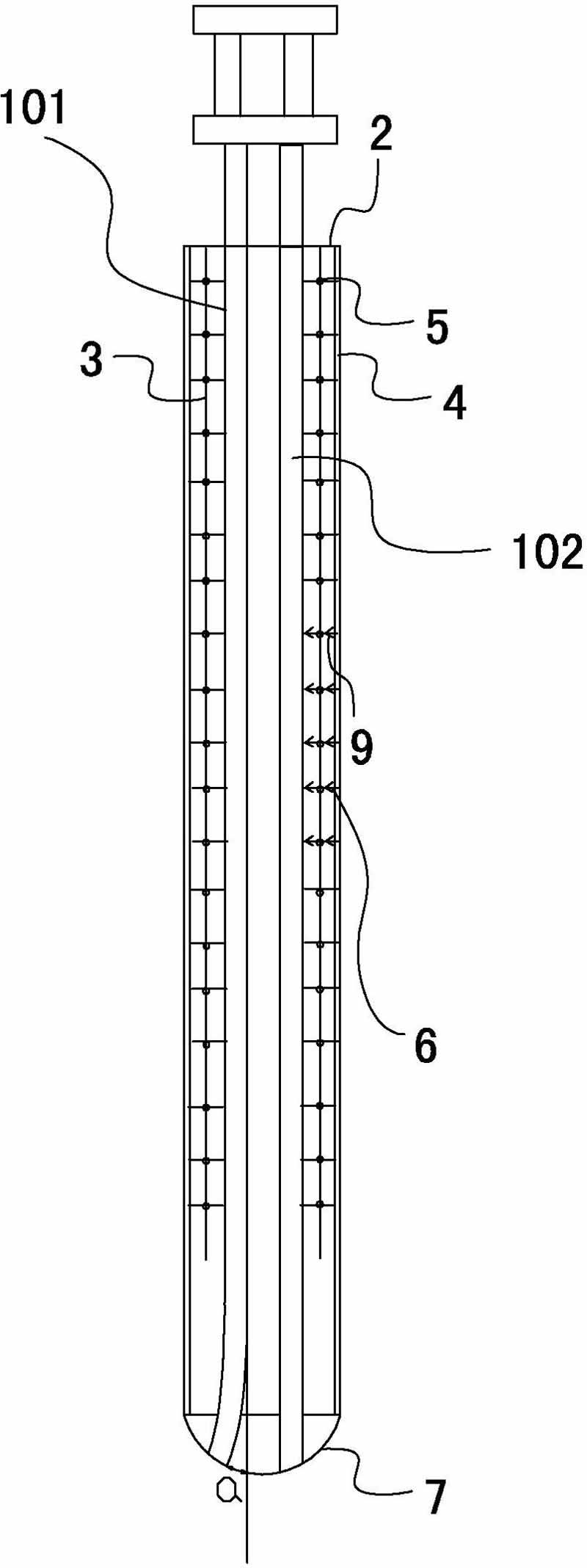

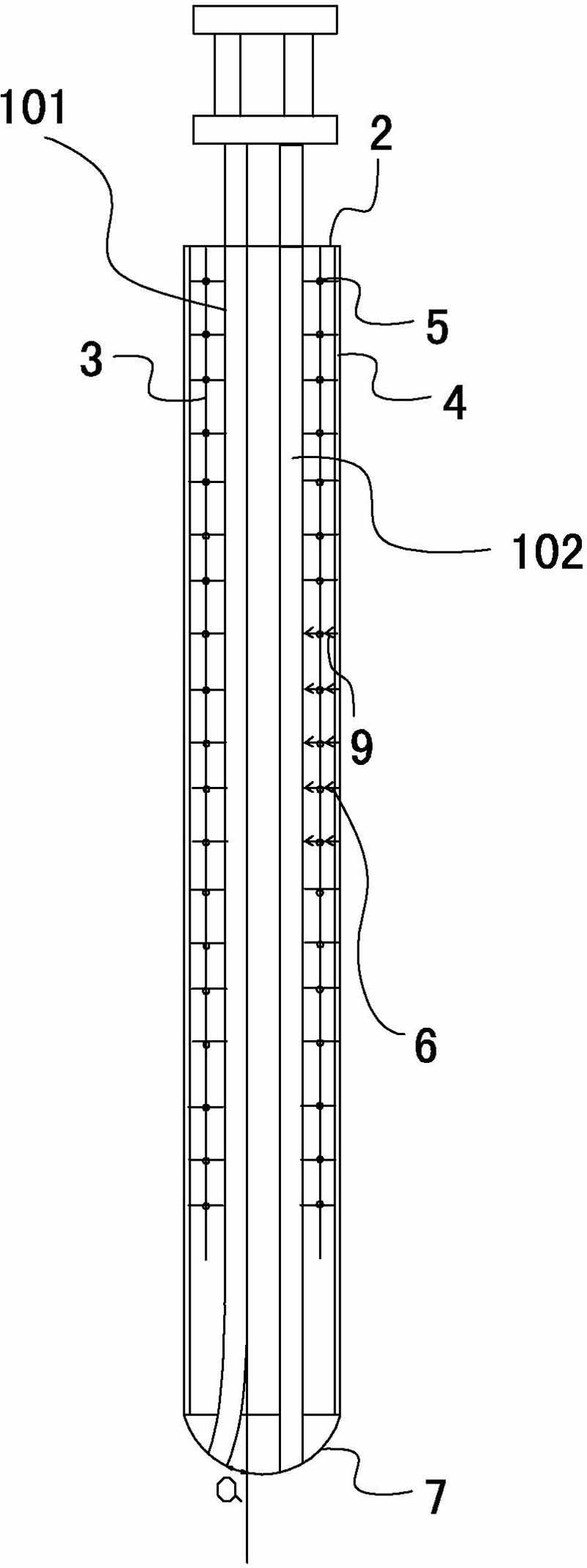

[0012] As shown in the figure, the built-in elbow desulfurization spray gun includes a gun body 2; the gun body 2 includes a first pipe 101, a second pipe 102, a refractory material layer 4, a skeleton 3 and a ring rib 5; the skeleton 3 Placed in the refractory material layer and fixedly connected with the first pipe 101 and the second pipe 102; the annular rib 5 is fixedly connected with the first pipe 101 and the second pipe 102 through the transverse rib 6; the first pipe 101 tail eccentric angle 20°≤a≤35°; the second pipeline 102 adopts a straight-through type.

[0013] The body bottom 7 of the gun body 2 of the present invention is hemispherical. The hemispherical body bottom 7 can effectively improve the stress state of the gun body, and eliminate the vibration caused by the melt movement.

[0014] In order to strengthen the effect of stress distribution, the annular ribs 5 in the present invention are several concentric annular ribs. This structural design can effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com