Washing machine with adjustable backwater height

A washing machine and adjustable technology, applied in the field of washing machines, can solve the problems of affecting the washing power of clothes, the washing effect cannot be guaranteed, and the number of clothes to be washed is different, so as to achieve good washing effect and ensure the effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

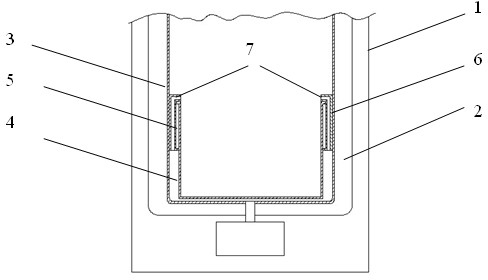

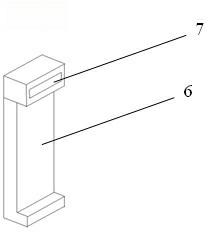

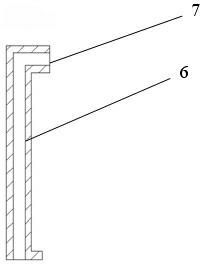

[0010] Such as figure 1 , the present invention includes a box body 1, a water tank 2, a washing bucket 3 is installed inside the water tank 2, a water flow channel 4 is arranged in the washing bucket 3, a return water cover plate 6 is installed in the water flow channel 4, and a water flow channel 4 is also provided with Slot 5, the position of return water cover plate 6 can move up and down. The backwater cover plate 6 is hollow inside, the bottom is provided with a water return port, the top is provided with a water spray port, and both ends are provided with protrusions, and the raised parts adjust the height of the return water cover plate 6 by inserting into different positions of the slots 5 . figure 2 It is a structural schematic diagram of the movable backwater cover plate of the present invention, image 3 It is a sectional view of the movable backwater cover plate of the present invention. 7 is a water spout among the figure.

[0011] When washing clothes, accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com