Punching water supplement-based method for treating foundation by adopting dynamic compaction

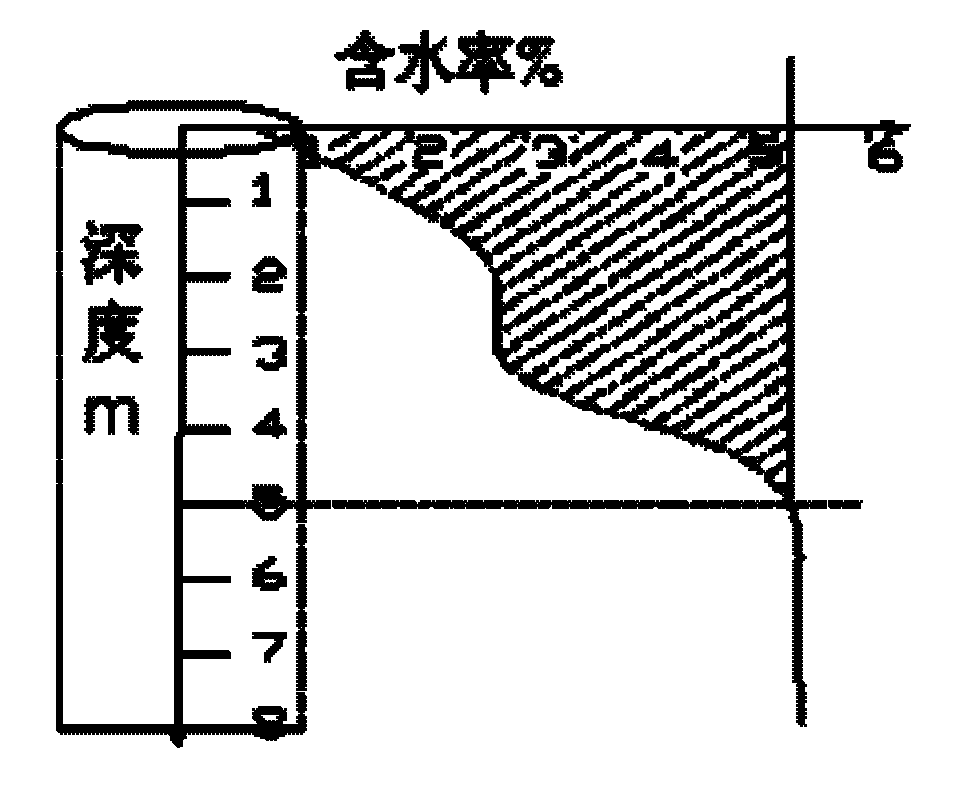

A technology of punching and water replenishment, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of high construction cost, large evaporation loss of water storage pit, uneven water distribution, etc., and simplify the water replenishment measurement work. , The effect of reducing construction costs and shortening the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

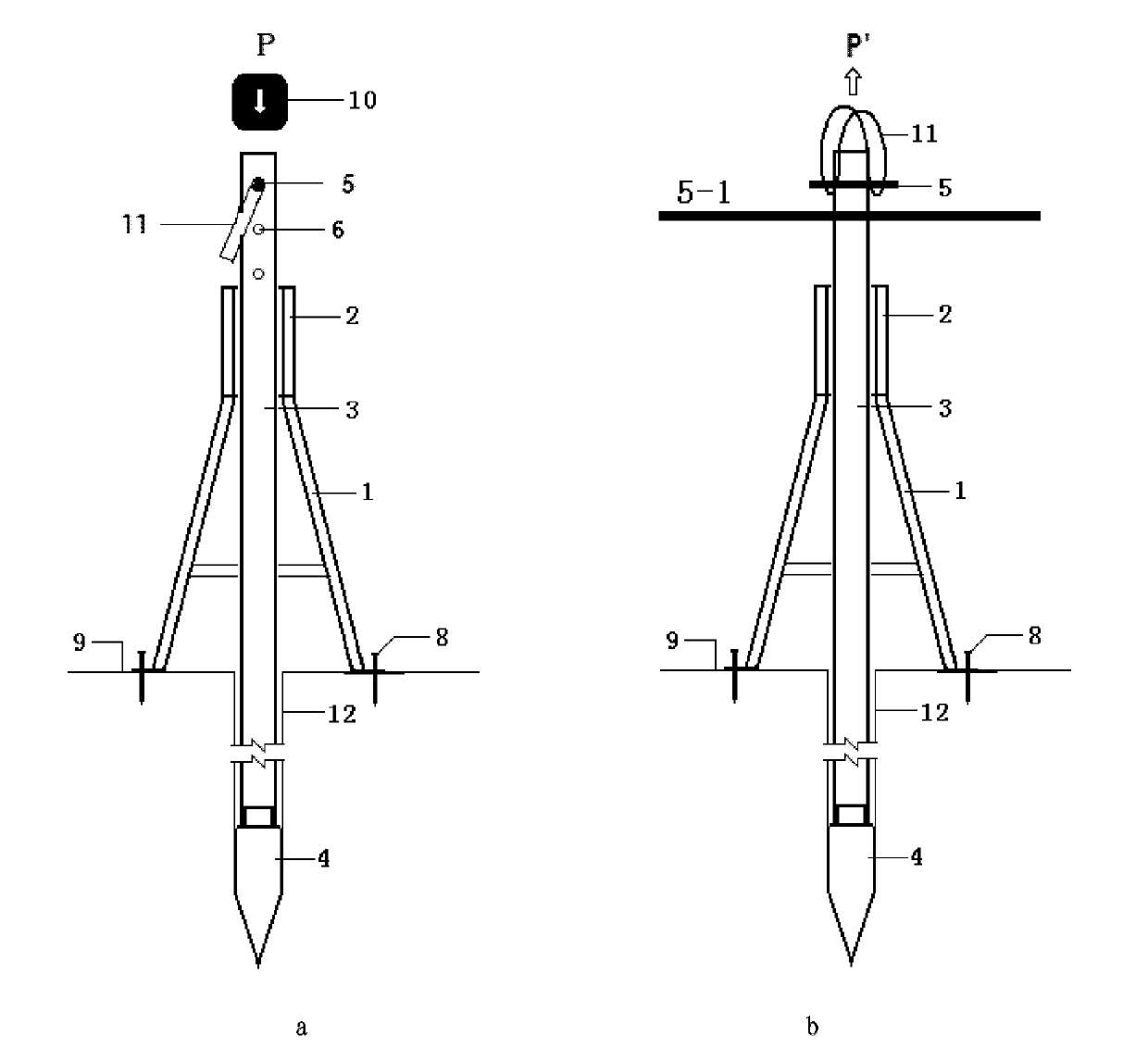

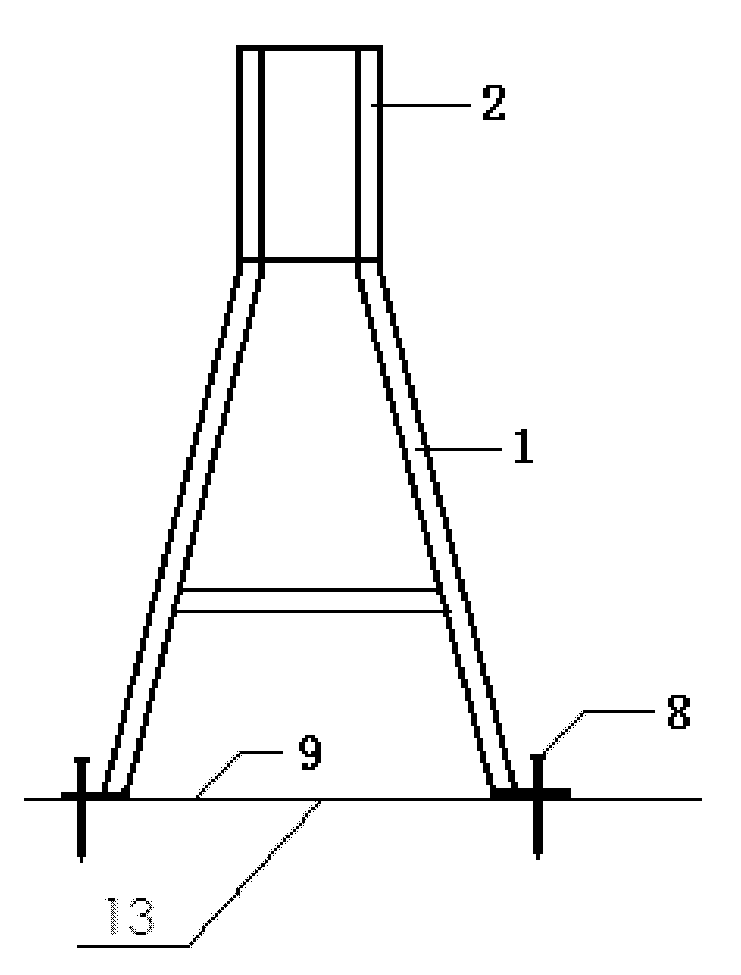

[0035] Such as Figure 2-Figure 6 As shown, the punching device involved in the method of the present invention includes an impact hammer 10 connected to the boom of the truck-mounted crane by a suspension rope, a support 1 and a guide pipe 2 vertically fixed on the ground 9. The center of the support 1 is aligned with the dynamic ram The center point 13, the guide tube 2 is pierced with a punching dowel 3, the lower end of the punching dowel 3 is connected with a punching cone 4 to align with the center point 13 of the dynamic compaction, and the upper and lower parts of the punching dowel 3 are provided with 2-3 afterburners The hole 6 is connected to the sling 11 through the booster rod 5. When punching, the impact hammer 10 performs multiple impacts on the upper end of the punching dowel 3 (applying the impact force P), until the punching cone 4 penetrates into the ground 9 to reach a predetermined depth ( figure 2 a); when lifting the rod, use the extended booster rod 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com