Full-length clamp connecting member for installing low carbon plate on building outer wall and using method of connecting member

A technology for connecting components and connectors, which is applied in the direction of building components, walls, building structures, etc., can solve the problems of high technical conditions for operators, poor firmness compared to pre-embedded, waste of skeleton materials, etc., and achieve simple and fast installation process, The effect of light overall weight and small building load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

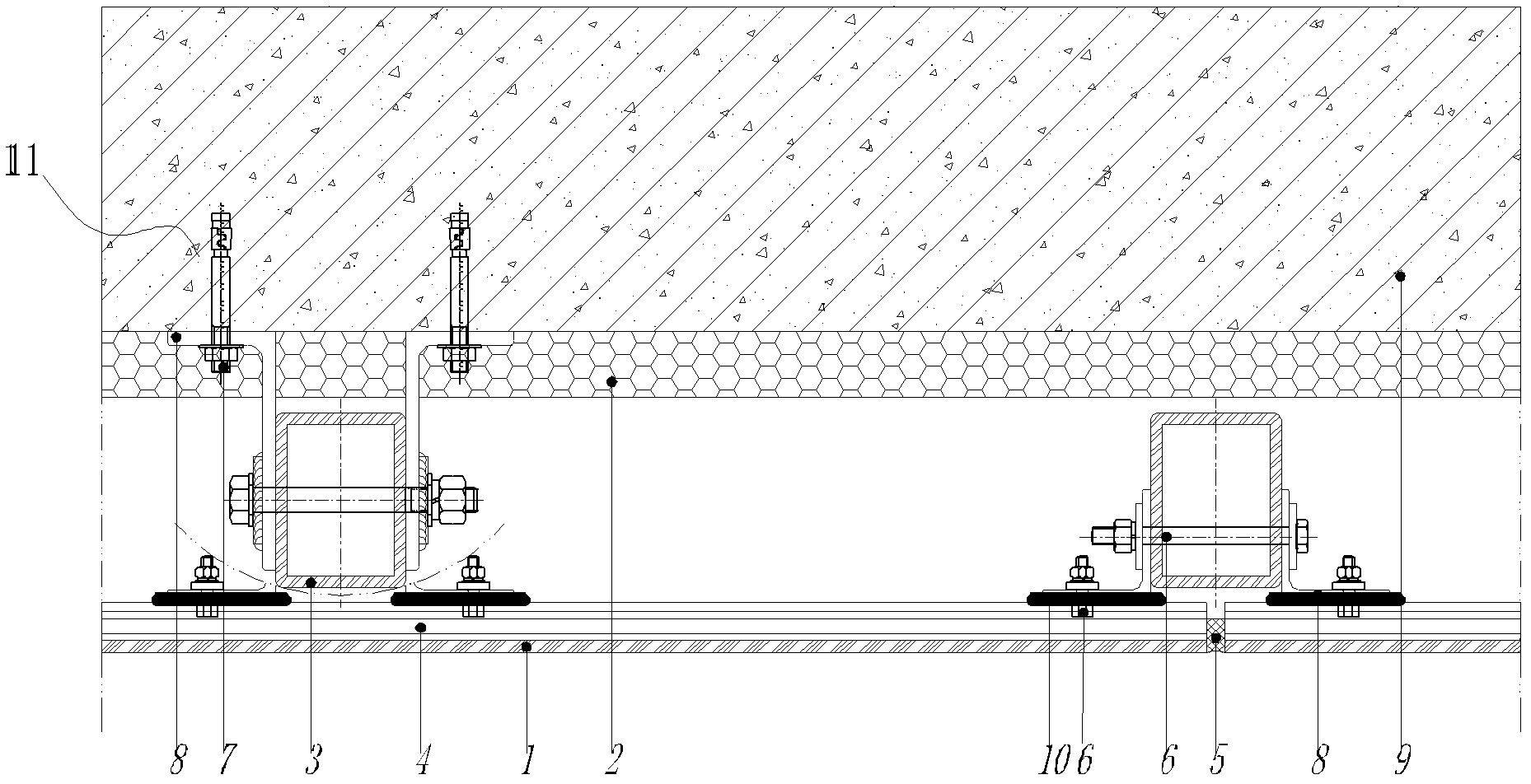

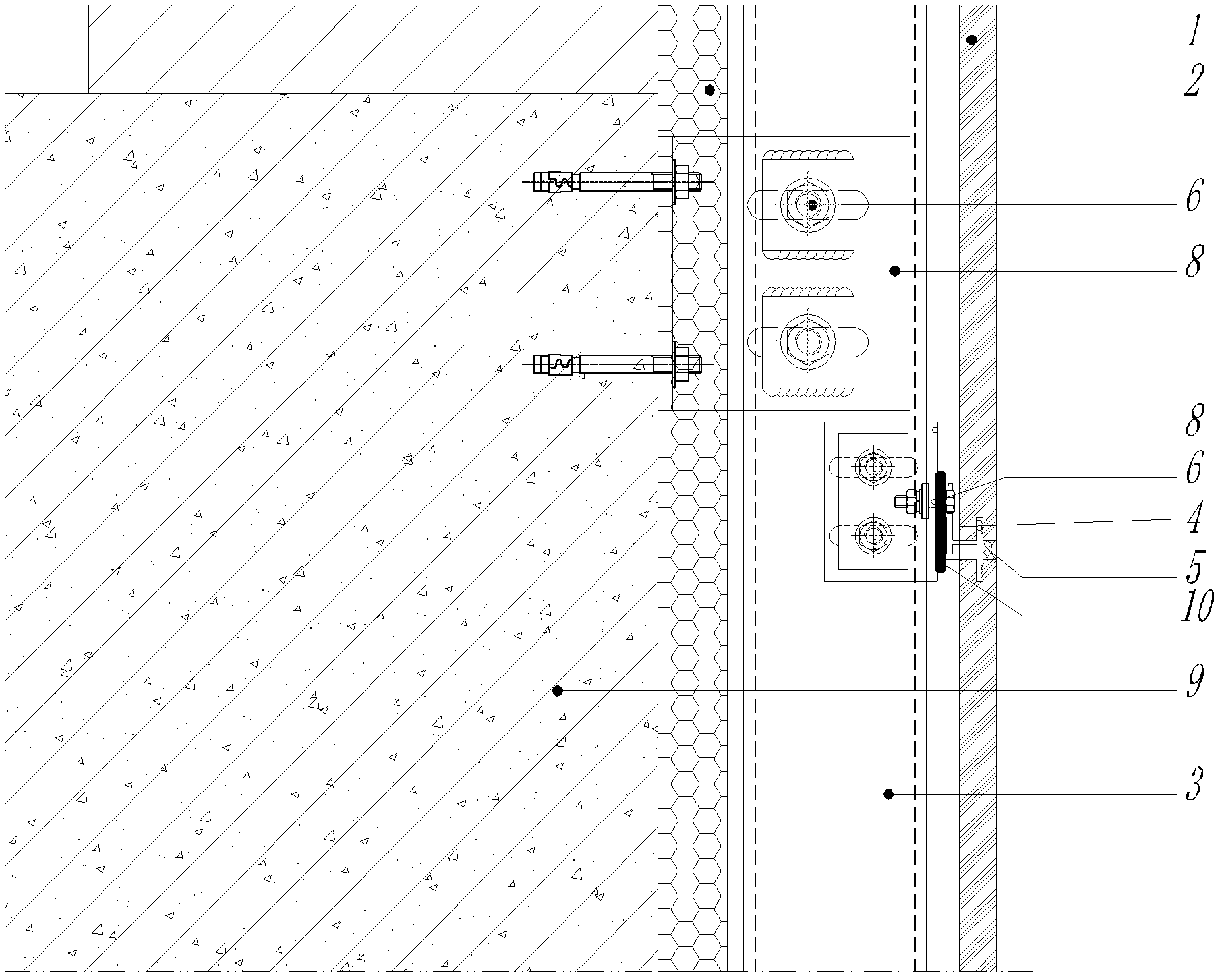

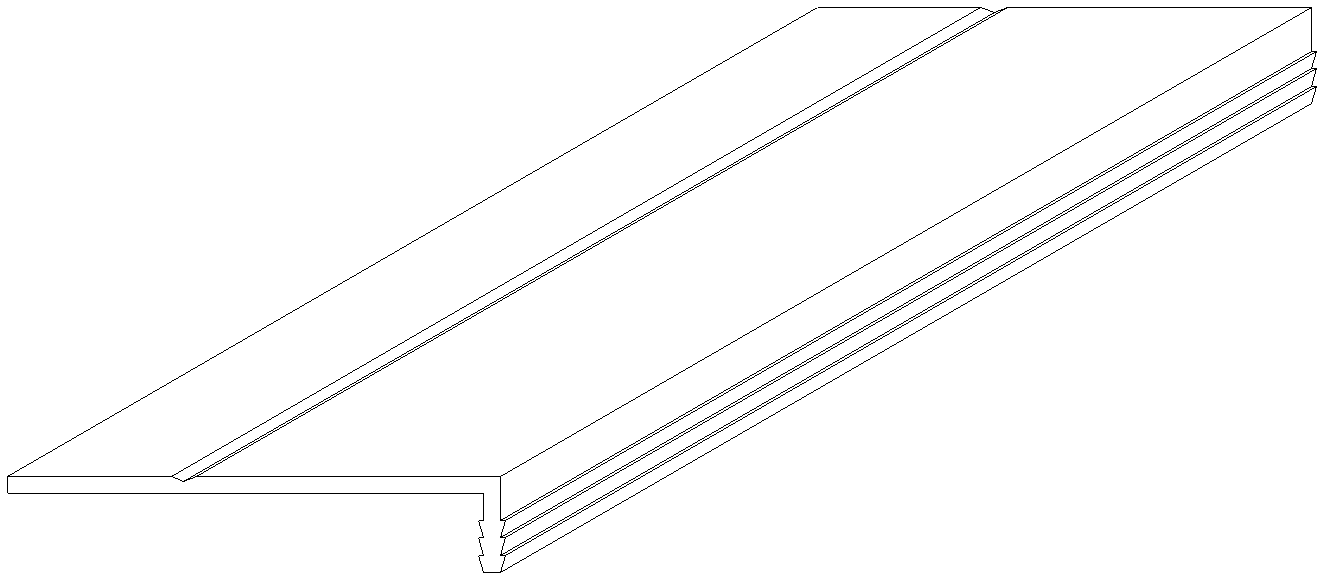

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, it is a full-length clip connecting member for installing low-carbon boards on the eaves wall of a building. The full-length clip connecting member includes a pre-embedded connecting piece 11, a receiving piece 8, a keel 3 and a full-length clip 4. The pre-embedded connector is composed of a pre-embedded connector body, expansion bolts 7 and fastening bolts 6. The pre-embedded connector body is an angle steel member with long and short sides. Fixed connection, the keel is connected to the receiving part, and the one side of the receiving part is connected to the full-length clip. The full-length clip is composed of an upper clip or a middle clip or a lower clip and fastening bolts.

[0023] The body of the pre-embedded connector is a custom-made perforated angle steel with 1-2 ¢8mm×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com