Automatic gearbox

A technology of gear box and gear box cover, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of large closing action noise, large motor volume, affecting product quality, etc., and achieve high output torque. , Small size, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

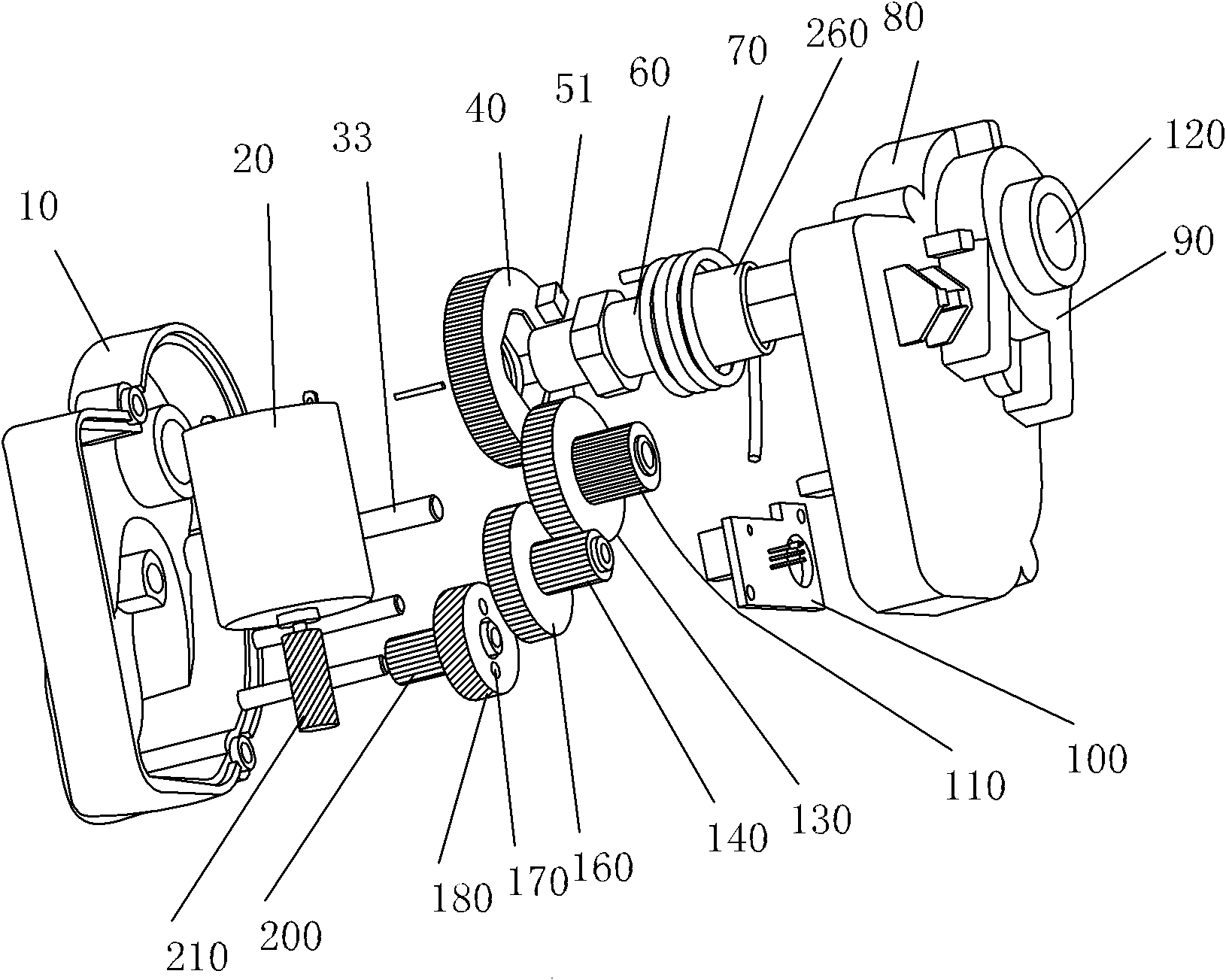

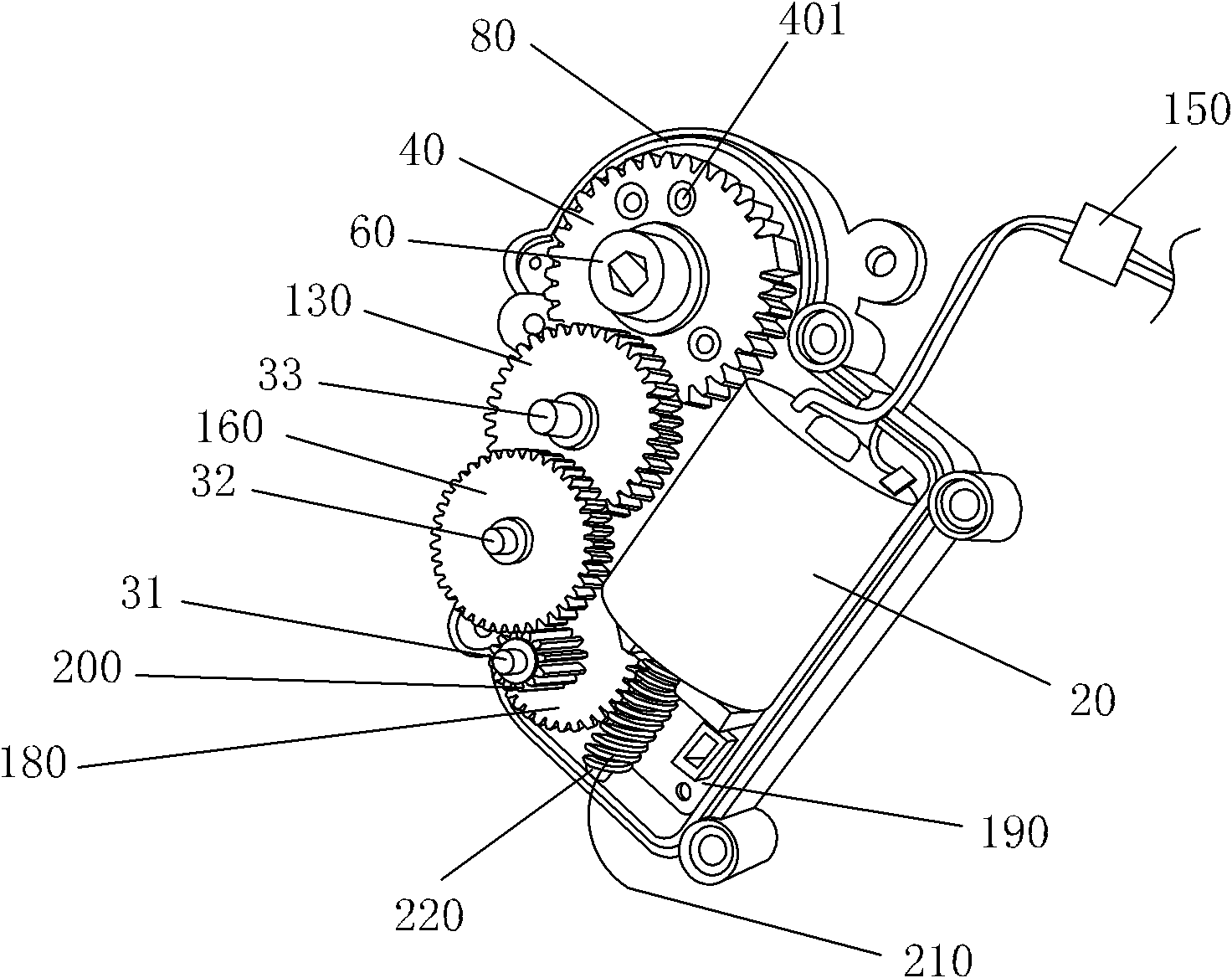

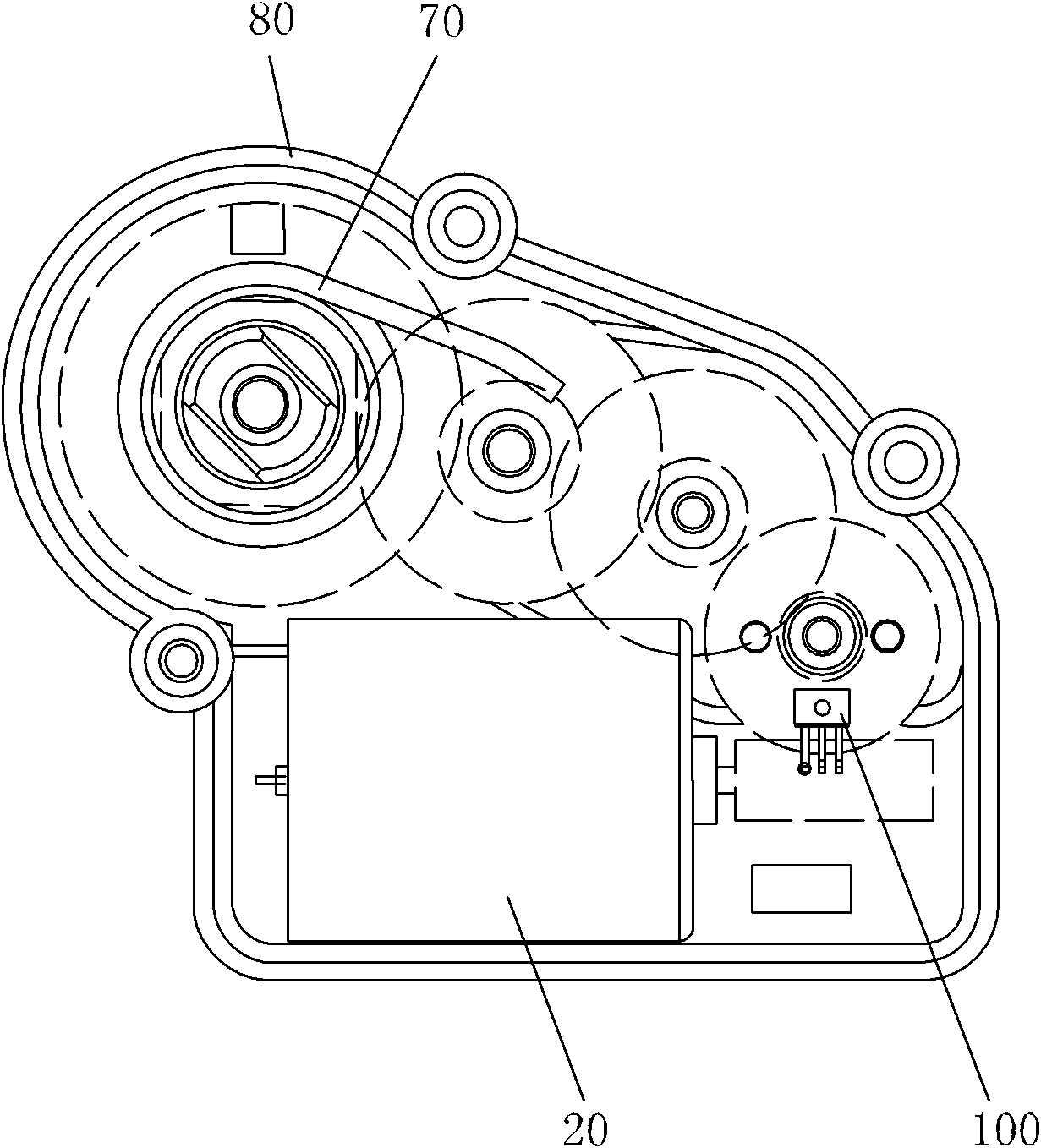

[0025] The present invention will be further described below with specific embodiment, see Figure 1-6 :

[0026] In this embodiment, the automatic gearbox is applied to the toilet lid and seat of the smart toilet:

[0027] The automatic gearbox includes a gear box seat 80, a gear box cover 10 and a gear set. The gear box seat 80 and the gear box cover 10 form a cavity, and the gear set is installed in the cavity. The gear set includes: The power input gear 210 connected to the output unit, several intermediate transition gears including the transmission shaft 30 and the large and small gears arranged on the transmission shaft 30 and including the power output rotating shaft 60 and being arranged on the power output rotating shaft 60 The output gear 40 of the output gear 40, the power input gear 210 meshes with the intermediate transition gear, the intermediate transition gear meshes with the output gear 40 and is output through the power output rotating shaft 60 of the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com