Color wheel, assembly method thereof, light source device and projection system using color wheel

A color wheel and wavelength conversion technology, applied in the field of light sources, can solve the problems of increased color wheel cost, increased area, expensive wavelength conversion materials, etc., and achieve the effect of reducing cost and small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

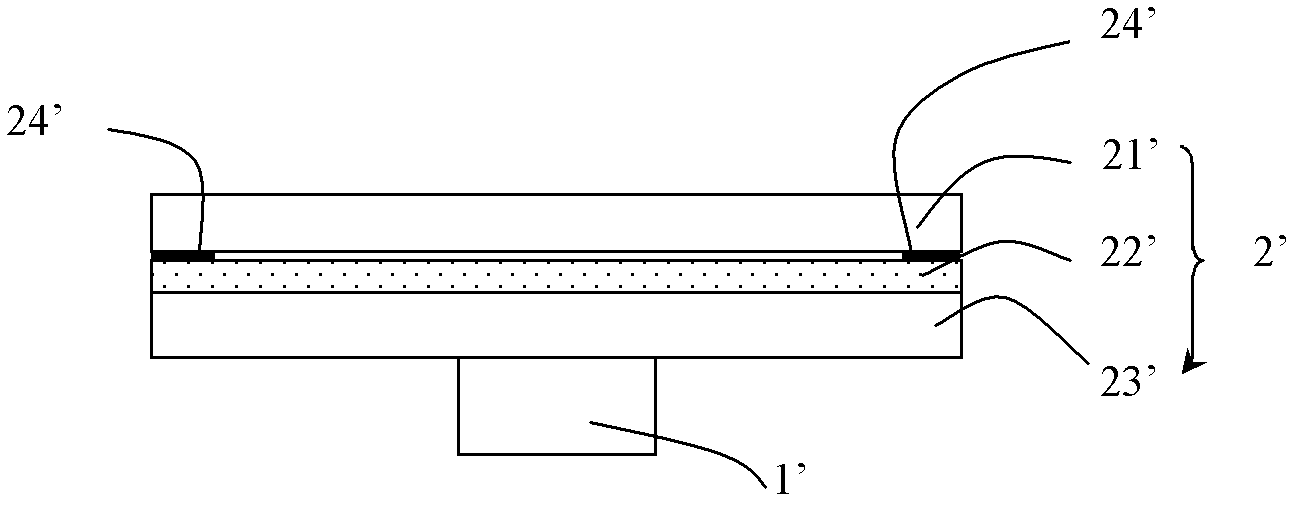

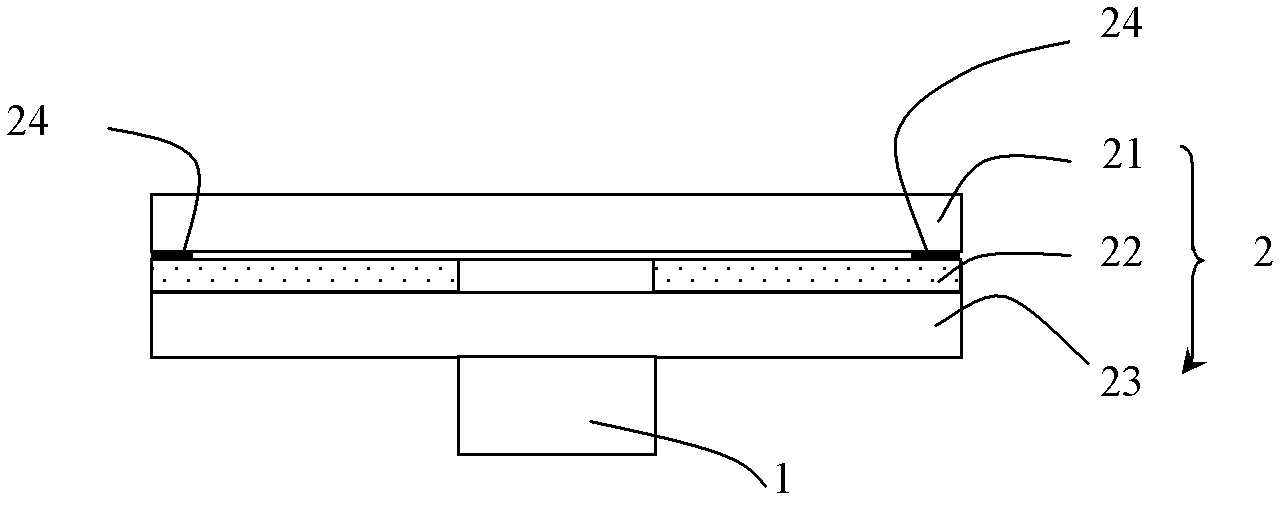

[0031] Figure 5 Shown is the first embodiment of the assembly method of the color wheel of the present invention, including the following steps:

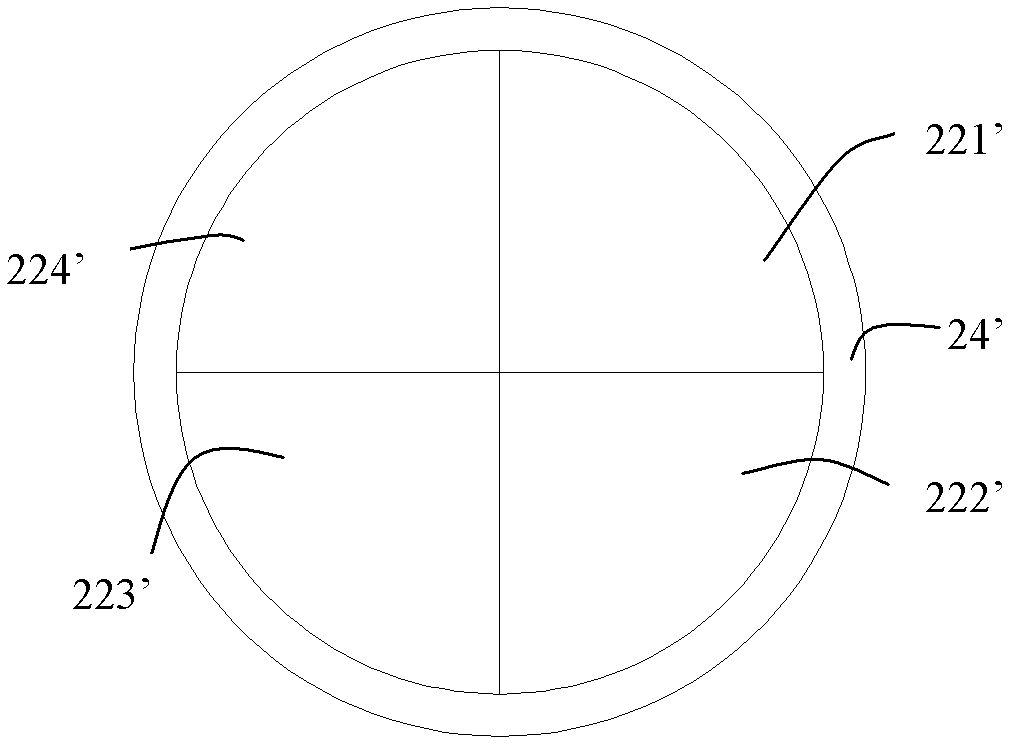

[0032]S1, stacking the wavelength conversion sheet and the first base layer, the first side of the wavelength conversion sheet is adjacent to the first base layer, the wavelength conversion sheet includes at least one wavelength conversion section, and the wavelength conversion section includes an integrally formed wavelength conversion part and at least one fixing part protruding from the outer edge of the wavelength converting part.

[0033] The wavelength conversion sheet includes at least one wavelength conversion section, and each wavelength conversion section can convert excited light different from the color of the excitation light when irradiated by the excitation light. In this step, for the convenience of operation, when the optical wavelength conversion sheet and the first base layer are stacked, they can be stacked hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com