Method for controlling deformation of tank wall at hanging shaft of oil tank

A hanging shaft and box wall technology, which is applied in the field of transformers, can solve problems such as box wall deformation, high rigidity at the hanging shaft, flatness and internal dimension tolerance, etc., to improve labor production efficiency, improve product quality, and ensure flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

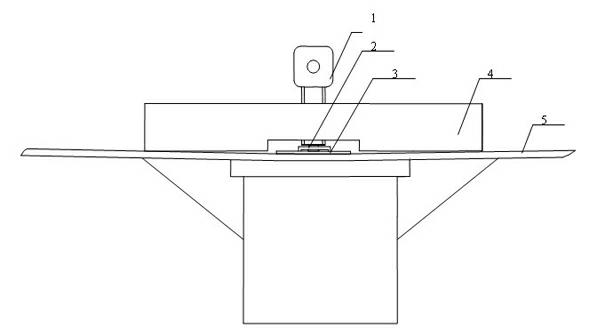

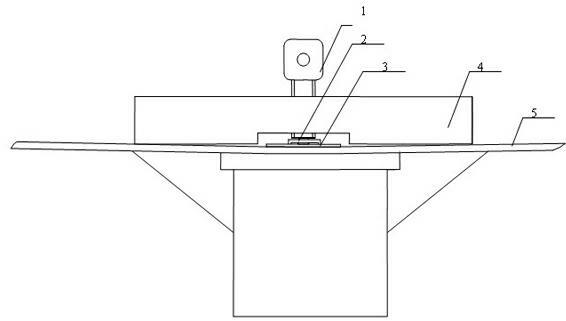

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0012] A method for controlling the flatness of the tank wall at the suspension shaft of the fuel tank, comprising the following steps: ① Fix a rigid fixing plate 2 with a tightening screw 1 on the back of the tank wall 5 at the suspension shaft, and the tightening screw is perpendicular to the rigid fixing plate For installation, a groove is provided on the side of the rigid fixed plate close to the box wall at the hanging shaft; ②A backing plate 3 is set at the groove, and a clamping plate 2 is provided on the top of the tightening screw, and the backing plate is close to the back of the box wall at the hanging shaft , the clamping plate is located outside the backing plate; ③ Rotate the tightening screw, and the tightening screw pushes the clamping plate against the backing plate, compacts the backing plate, and then completes the welding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com