Paper ingot folding machine

A folding machine, ingot technology, applied in the direction of cardboard items, etc., can solve the problems of low production efficiency, uneven paper, high labor intensity, etc., and achieve the effects of high production efficiency, cost saving, and labor intensity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

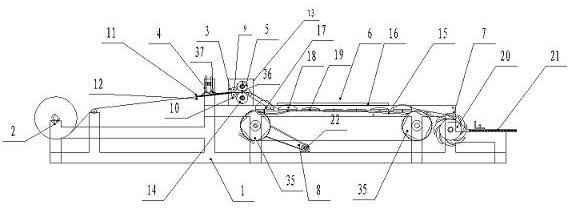

[0043] Examples such as figure 1 As shown, a paper ingot folding machine includes a frame 1 on which a paper roll fixing device 2, a paper tape traction device 3, a parallel paper edge folding device 4, a paper tape cutting device 5, and paper oblique folding devices are sequentially arranged on the frame. Device 6 and delivery device 7 and power drive device 8 .

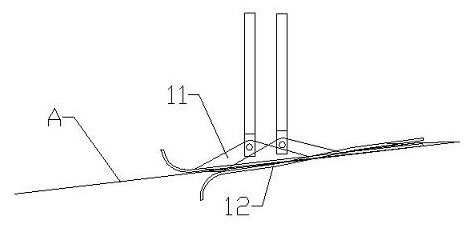

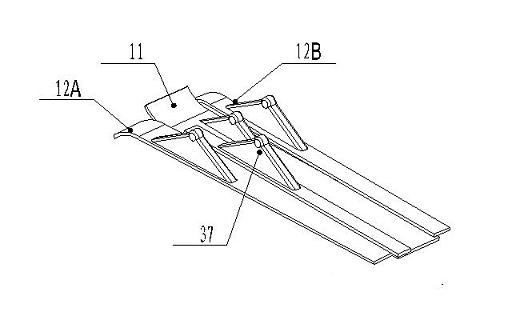

[0044] Such as figure 2 , image 3 , Figure 4As shown, the parallel paper edge folding device 4 includes an upper folded plate 11 and a lower folded plate 12 that are X-shaped three-dimensional intersections, and the lower folded plate 12 includes a first lower folded plate 12A and a second lower folded plate 12B. The lower folded plate 12A and the second lower folded plate 12B are respectively located on both sides of the upper folded plate 11, and the front ends of the first lower folded plate 12A and the second lower folded plate 12B are respectively provided with a downwardly bent bent portion. Located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com