Bottle neck guide rail device of empty bottle conveying system

A technology of conveying system and guide rail device, applied in the directions of transportation and packaging, packaging, bottle filling, etc., can solve the problems of high operating level requirements of adjustment personnel, affecting the efficiency of filling production, low adjustment efficiency, etc., so as to reduce high-altitude operations. risk, saving time and labor, regulating efficiency gains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

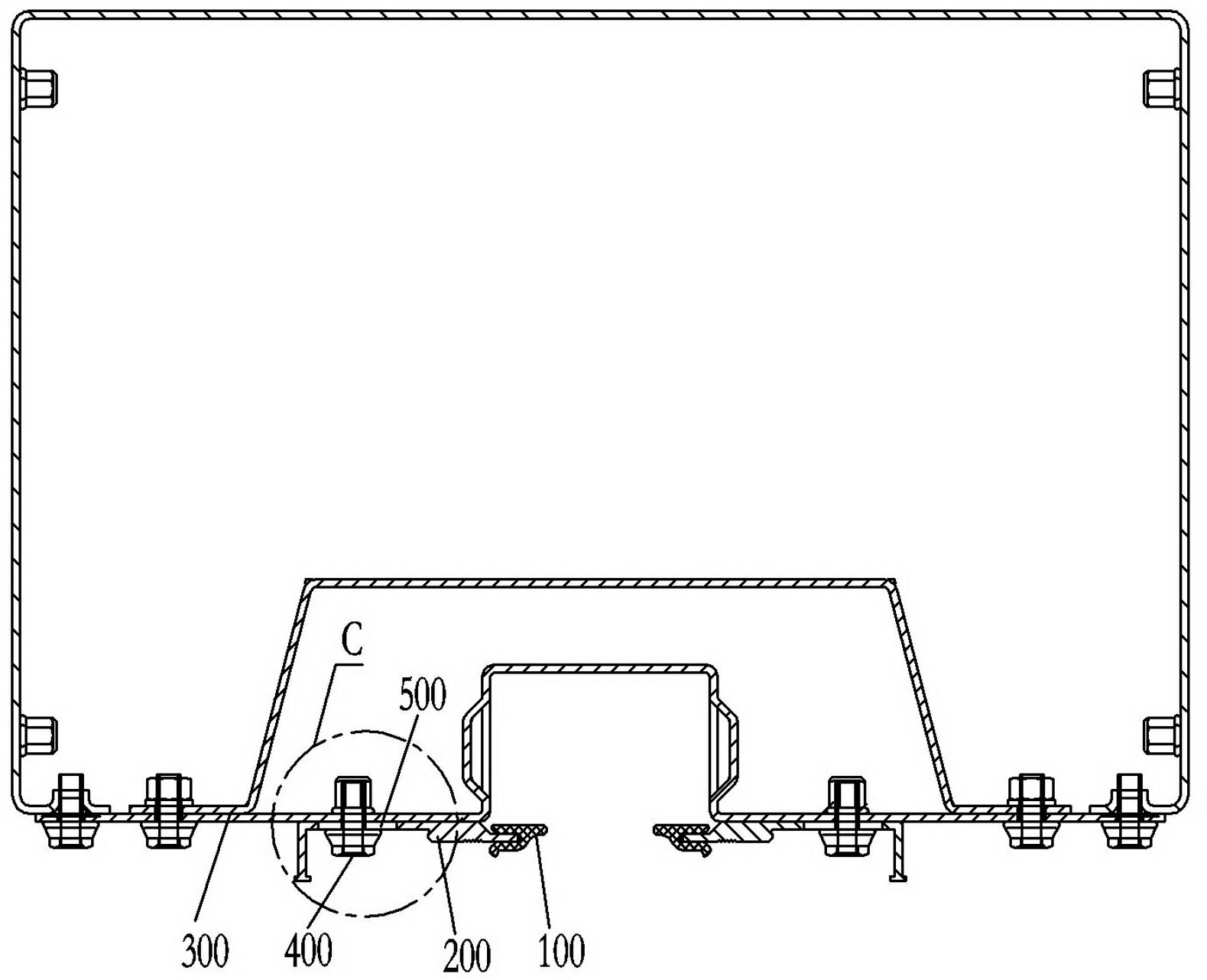

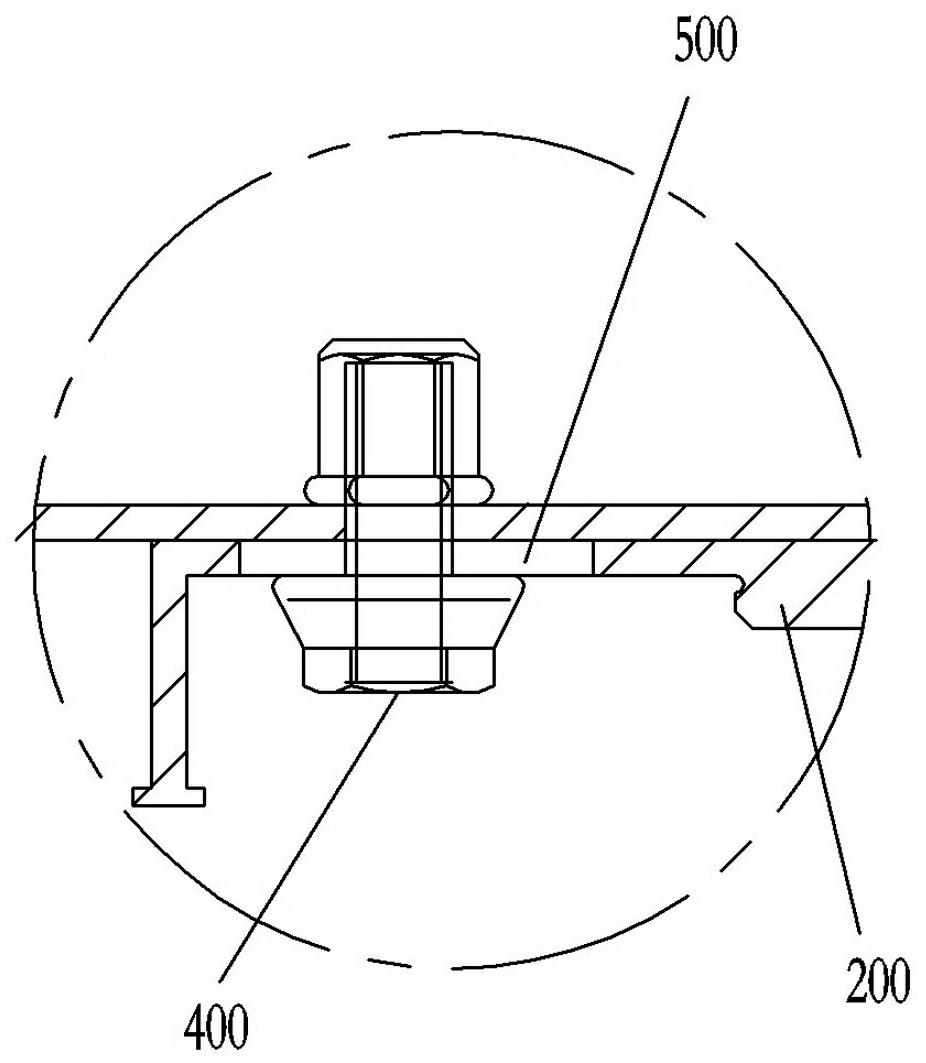

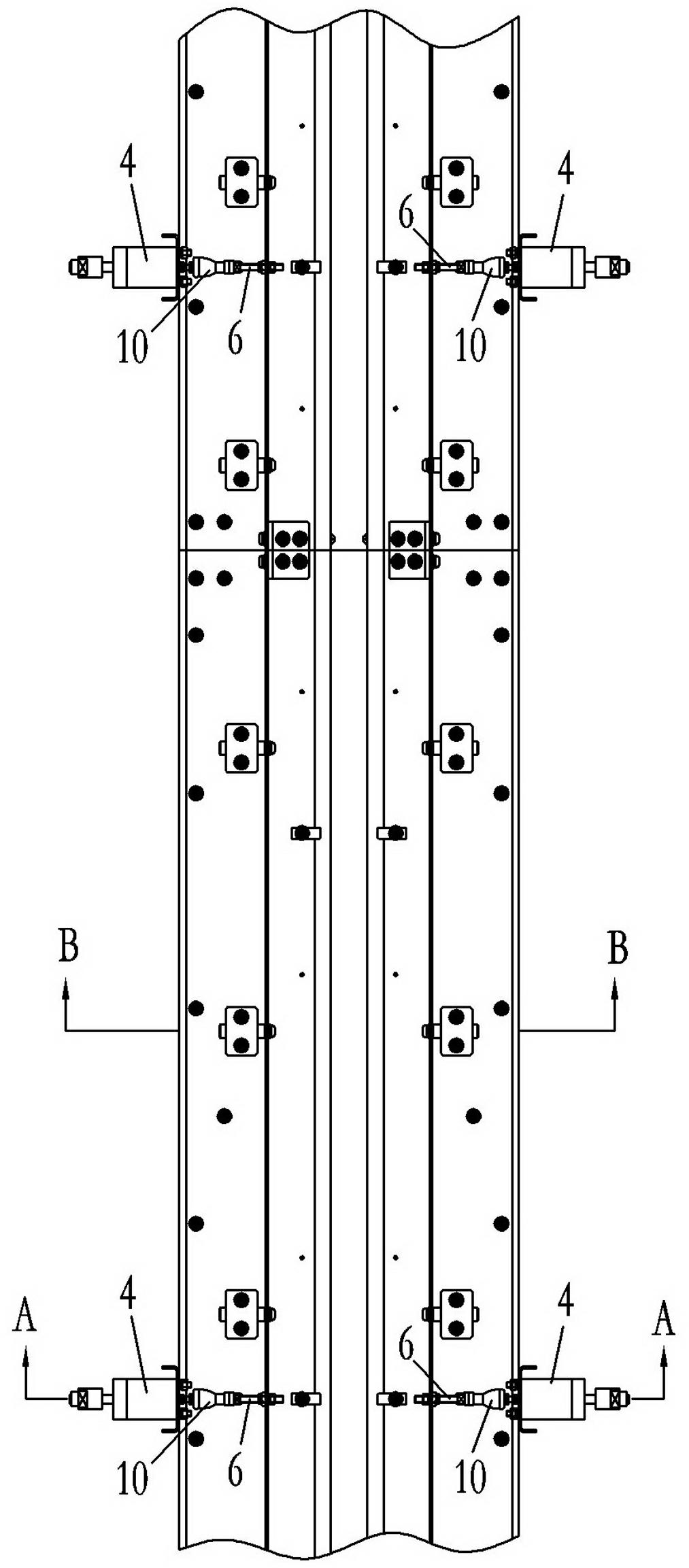

[0015] Such as Figures 3 to 7 As shown, the empty bottle conveying system of the present invention includes a bracket 1 and a housing 2 connected to the bracket 1, and the bottle neck guide rail device includes a bottle guide bar support plate 3, and a transmission device 4 capable of linear reciprocating motion , the bottle guide bar support plate 3 is equipped with a bottle guide bar 5, the transmission device 4 can be an air cylinder or a hydraulic cylinder, etc., and its quantity can be set according to the specific situation (such as the length of the conveying line), and the transmission device 4 is fixed on the bracket 1 , the bottle guide bar support plate 3 is connected with the connecting rod 6, and the other end of the connecting rod 6 is connected with the transmission device 4, and can drive the bottle guide bar 5 to move towards or in the opposite direction under the drive of the transmission device 4, and the transmission device The range of driving the movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com