Method for manufacturing electric registance stone

A manufacturing method and stone technology, applied in the field of resistance stone and its manufacture, can solve the problems of durability, environmental toxicity, incomplete understanding of resistivity and wear resistance, etc., to achieve wear resistance Excellent, the effect of reducing step-to-step voltage and contact voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

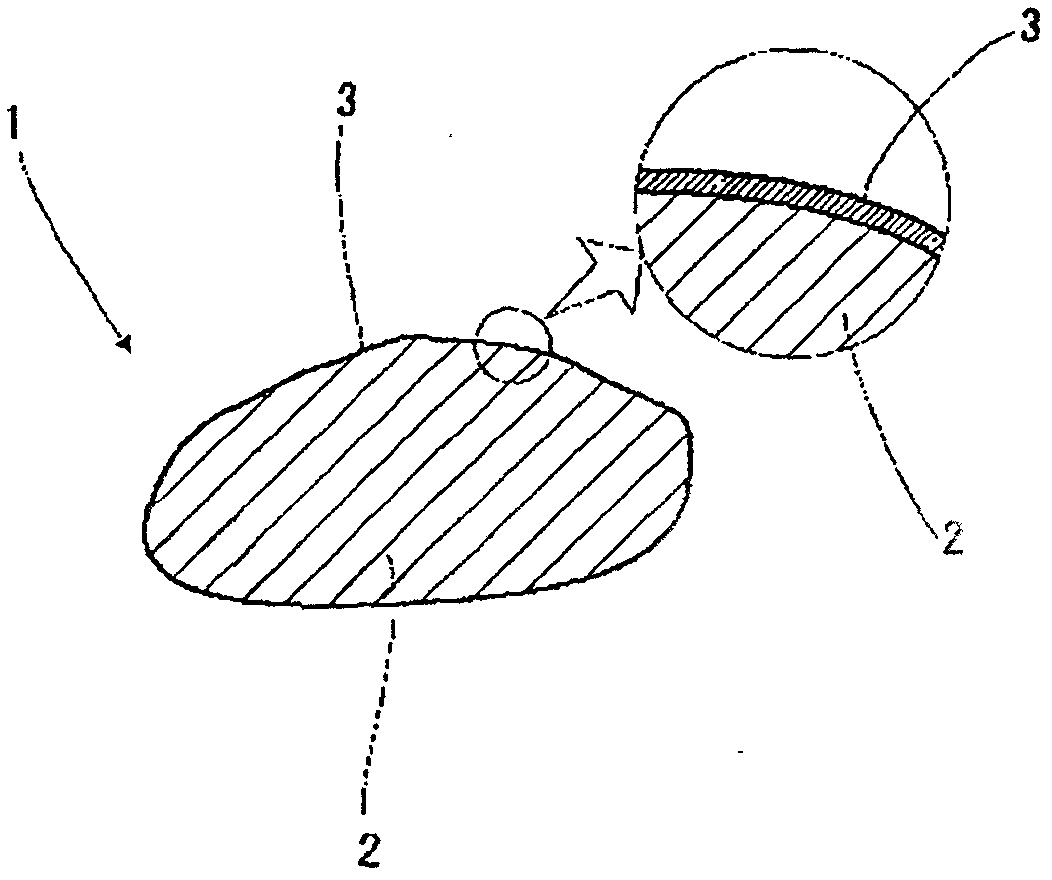

[0066] Embodiments of the present invention will be described below with reference to the drawings. figure 1 The resistance stone material of the embodiment of the present invention is shown. As shown in the figure, the resistance stone material 1 is dried natural stone 2 with a particle diameter of 5 to 40 mm, and the surface of the dried natural stone 2 forms a The cured coating 3 of the platinum catalyst is a coating that provides waterproofness and non-water retention to the natural stone 2 .

[0067] [Example 1]

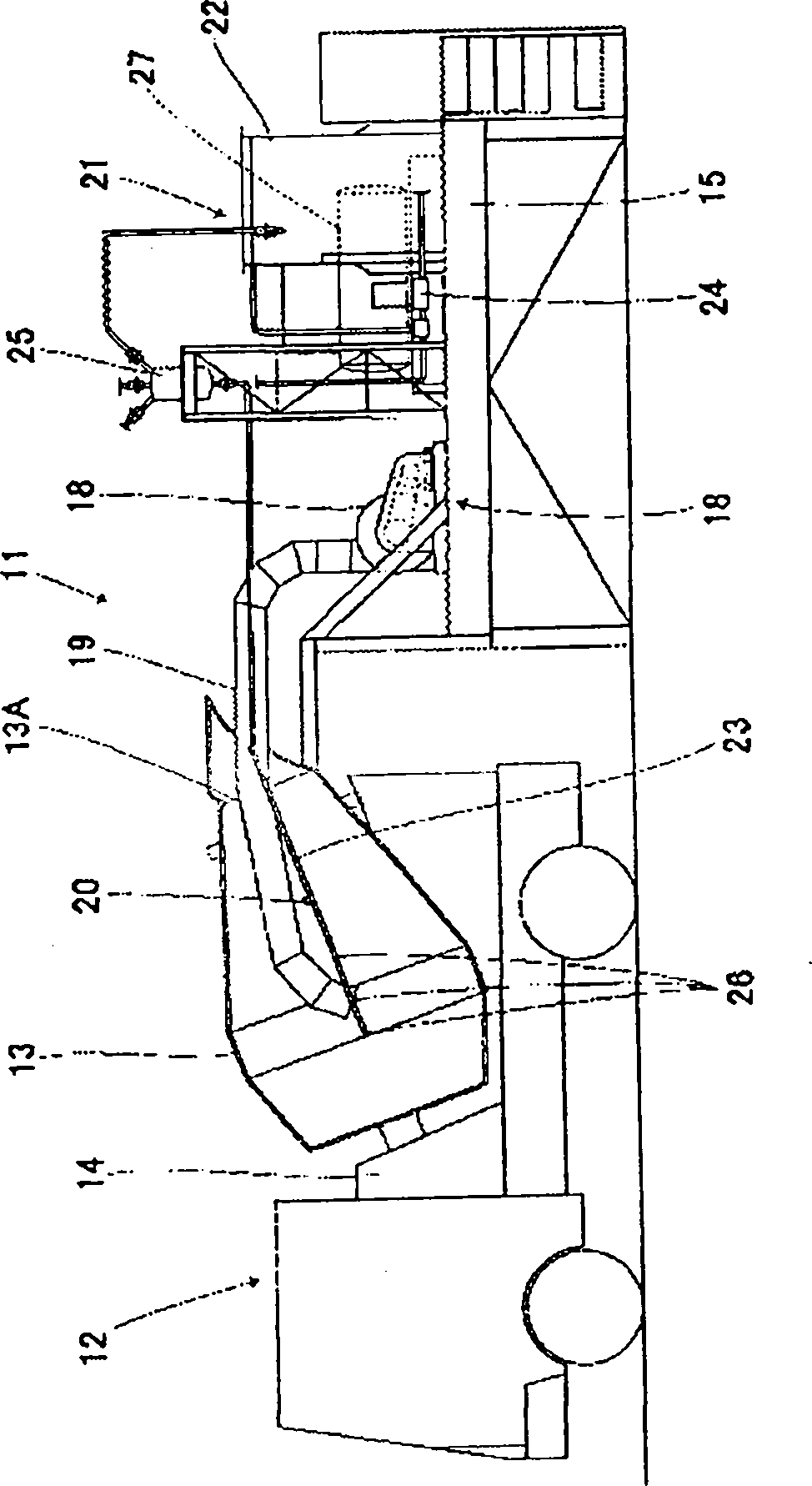

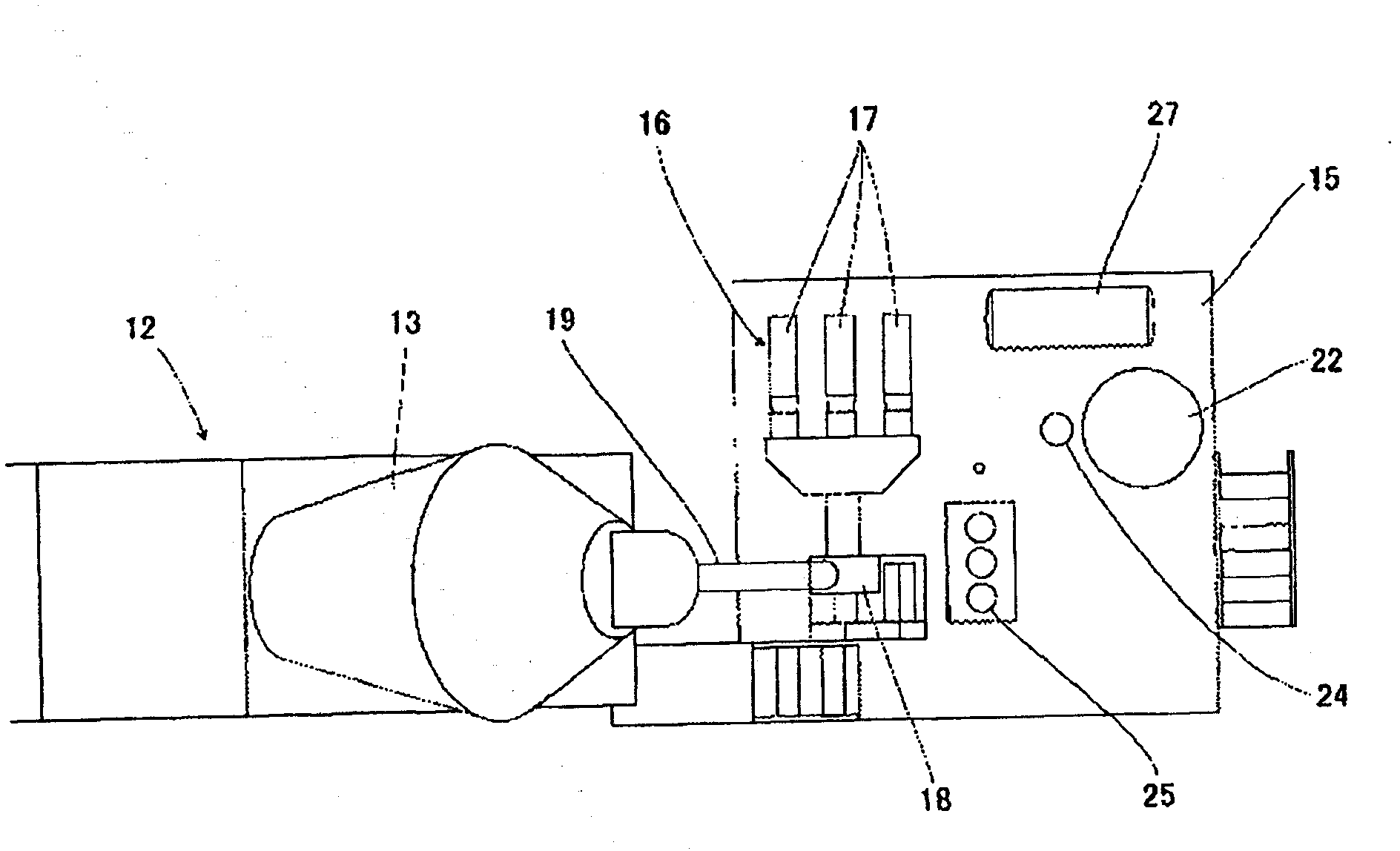

[0068] When describing the manufacturing device 11 of the resistance stone 1 and the manufacturing method using it, as figure 2 , image 3 As shown, the manufacturing device 11 is equipped with a fixed mixing device 12, and the mixing device 12 is provided with a rotary cylinder 13 that is rotatably inclined, and a rotary drive device 14 that rotationally drives the rotary cylinder 13, and the rotary drive device 14 can be used for all A hydraulic motor or t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com