Method of imparting water repellency to a gypsum-based product formed from a plaster-based composition

A raw gypsum-based, water-repellent treatment technology, applied in the field of manufacturing molded or extruded products such as gypsum bricks or gypsum boards, can solve the problem of reducing the water absorption of gypsum boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

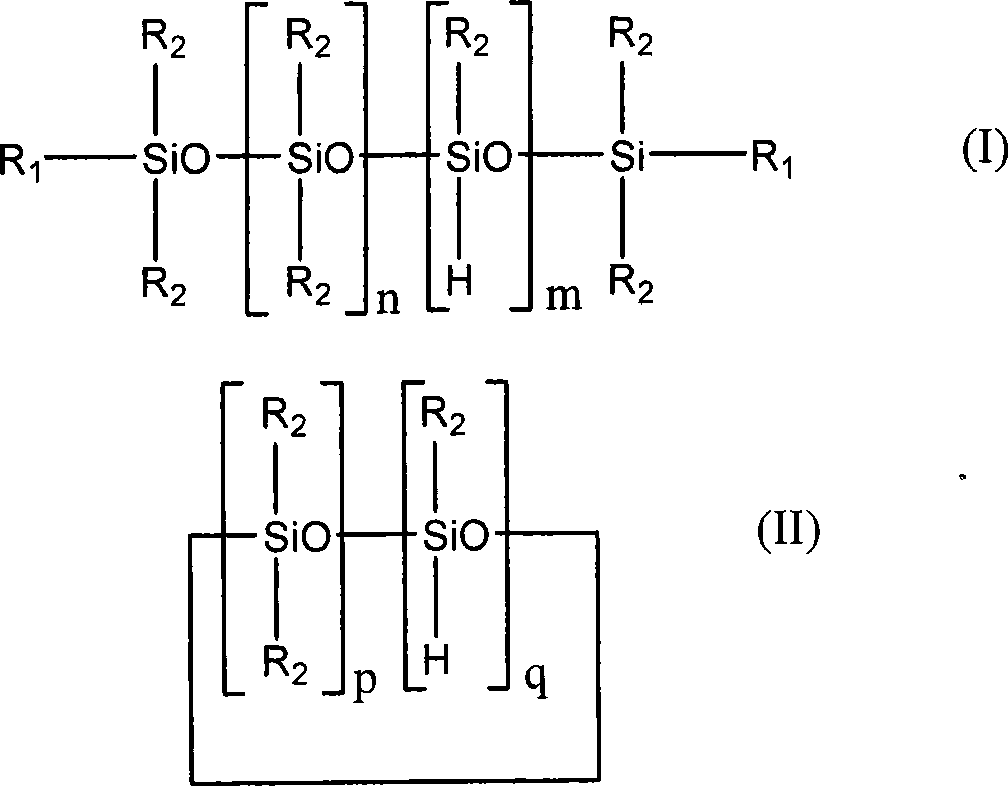

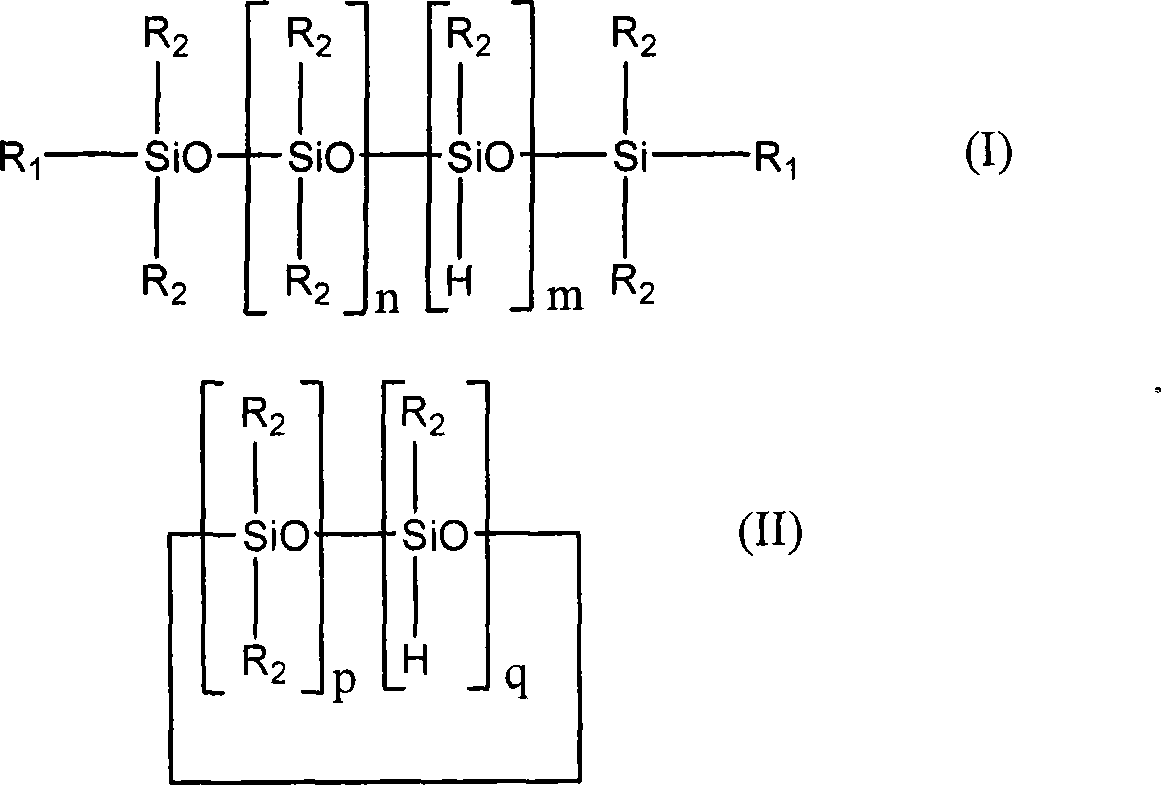

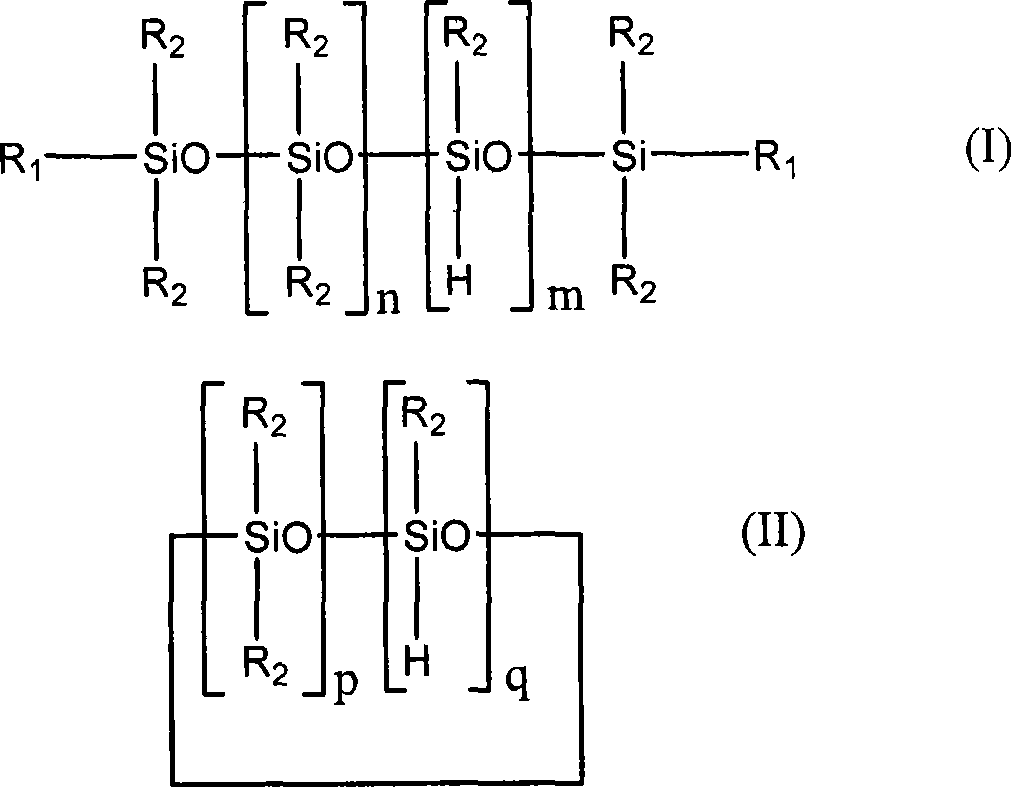

Image

Examples

Embodiment 1

[0060] 1) Preparation of small plates

[0061] Prepare a powder mixture consisting of the following components (amounts expressed relative to 1 kg of plaster of paris)

[0062] — 1kg of plaster of paris (based on natural raw gypsum)

[0063] - 4.25g guar gum or pregelatinized starch powder

[0064] - 4.7g starch (Collofilm 121, Amylum, Tate & Lyle)

[0065] - 0.05g coagulation retardant (PlastRetard, SICIT)

[0066] This mixture was added to a liquid mixture consisting of 740 g of water, 2.9 g of fluidizer (Proxmat M115-40, Synthron) and silicone oil (H68, Rhodia, France) (for the amount used see Table 1 below).

[0067] Mixing was performed by means of an 8 cm diameter dispersing disc rotating at 1500-2500 rpm.

[0068] During stirring for 1 to 1.5 minutes by means of an 8 cm diameter dispersing disc rotating at 1000 rpm, 52 g of foam were added, prepared by 2 g of blowing agent (Millifoam, Huntsman) in 200 ml of water.

[0069] This mixture was filled into 6 small pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com