Variable geometry turbine

A geometry and turbine technology that can be used in mechanical equipment, combustion engines, engine components, etc., to solve problems such as high financial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

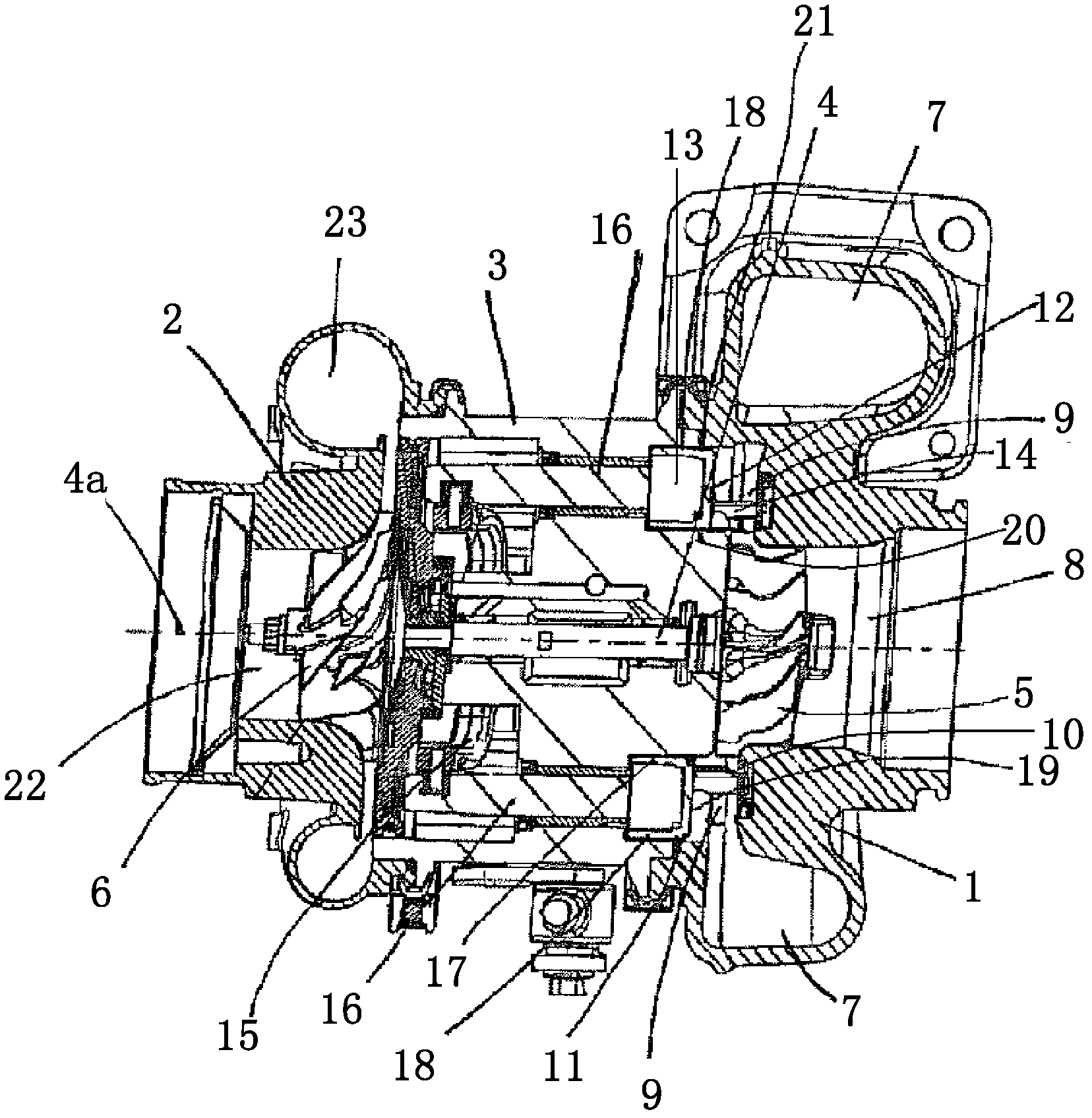

[0060] refer to figure 1 , which shows a known variable geometry turbocharger, wherein the turbocharger comprises a variable geometry turbine housing 1 and a compressor housing 2 interconnected by a central bearing sleeve 3 . The turbocharger shaft 4 extends from the turbine housing 1 to the compressor housing 2 via the bearing sleeve 3 . A turbine wheel 5 is mounted on one end of the shaft 4 for rotation within the turbine housing 1 and a compressor wheel 6 is mounted on the other end of the shaft 4 for rotation within the compressor housing 2 . The shaft 4 rotates about the turbocharger axis 4 a on a bearing assembly located in the bearing housing 3 .

[0061] The turbine housing 1 defines an inlet volute 7 to which gas from an internal combustion engine (not shown) is delivered. Exhaust gas flows from the inlet volute 7 to the axial outlet passage 8 via the annular inlet passage 9 and the turbine wheel 5 . The inlet passage 9 is delimited on one side by a surface 10 of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com