Spiral rod oil distribution energy storage plunger pump

A technology of screw and plunger pumps, which is applied in the field of hydraulic pumps, can solve the problems that the liquid and the plunger cannot be synchronized, and achieve the effect of alleviating momentum pulse and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

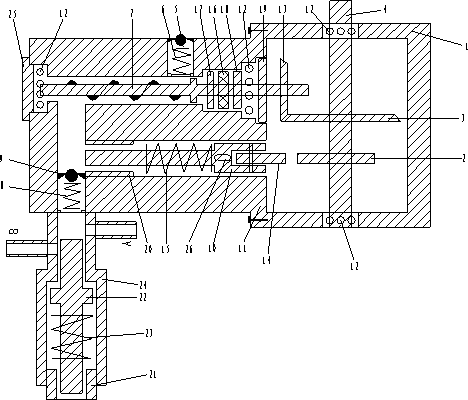

Embodiment 1

[0010] Embodiment 1: The plunger pump includes: main shaft housing 1, cam 2, driving bevel gear 3, main shaft 4, input check valve 5, input check valve spring 6, screw rod 7, output check valve spring 8, Output check valve 9, plunger 10, plunger pump casing 11, screw rod bearing 12, driven bevel gear 13, pulley 14, plunger spring 15, oil seal 16, lower gasket 17, upper gasket 18, method Lan 19, cylinder liner 20, pressure regulating hollow screw 21, sliding plug 22, sliding plug spring 23, energy storage safety valve 24, screw rod cavity screw 25, positioning keyway 26, working liquid outlet a and overpressure liquid outlet b ;

[0011] The main shaft housing 1 is connected with the plunger pump housing 11, the main shaft 4 is connected with the main shaft housing 1 through the screw bearing 12, one end of the main shaft 4 protrudes outside the main shaft housing 1, and the main shaft 4 in the main shaft housing is equipped with an active Bevel gear 3 and cam 2; the driving b...

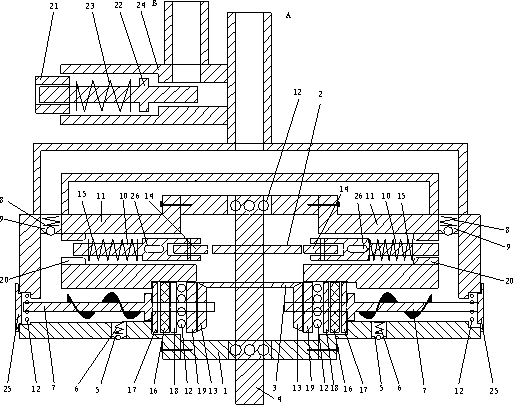

Embodiment 2

[0013] Example 2: In figure 2 Among them, two sets of schemes identical to those in Embodiment 1 are respectively installed on both sides of the main shaft 4, and the output check valve 9 of the two sets of technical schemes is jointly connected with the energy storage safety valve 24, and the outlet on the energy storage safety valve 24 The oil port a is the common oil outlet of the two groups of schemes, and the decompression outlet b is the common decompression port of the two groups of schemes. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com