Direct type backlight source of liquid crystal display screen

A liquid crystal display, direct type technology, applied in the field of direct type backlight, LCD backlight, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

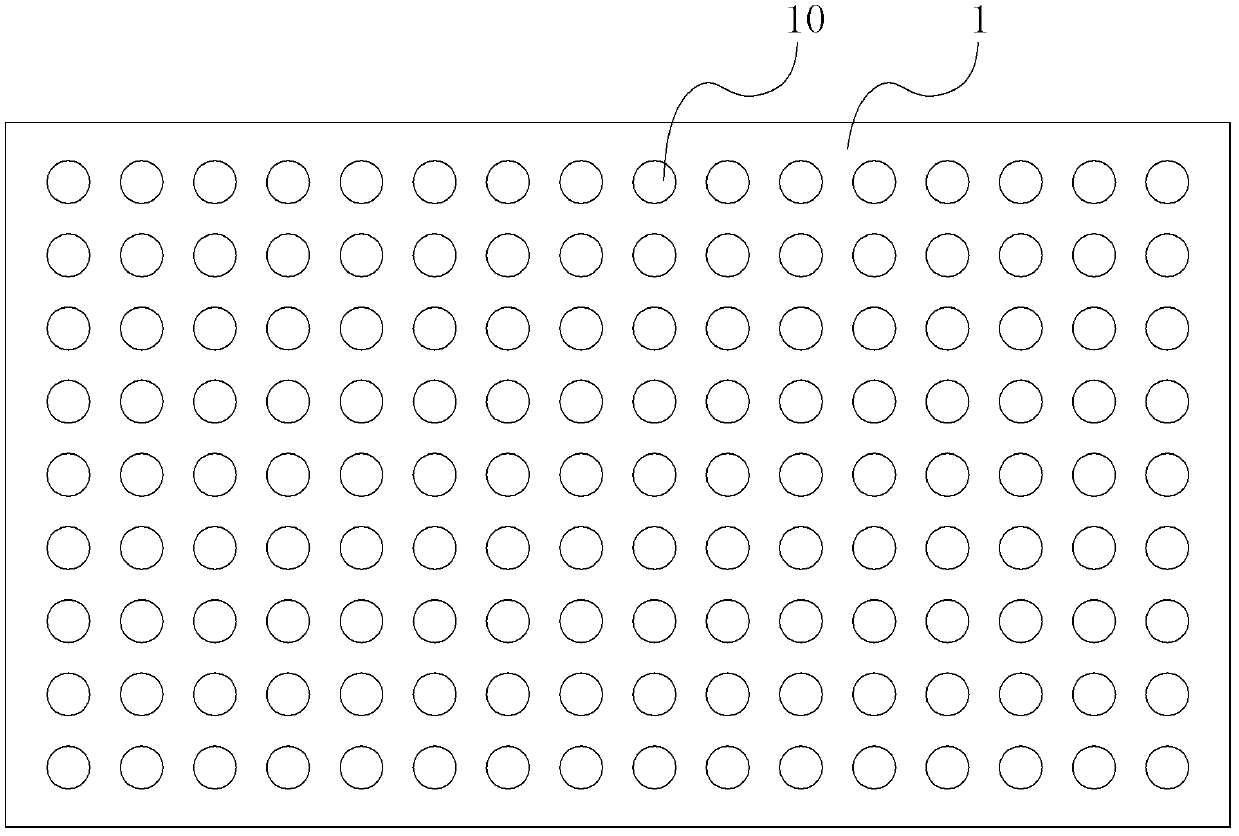

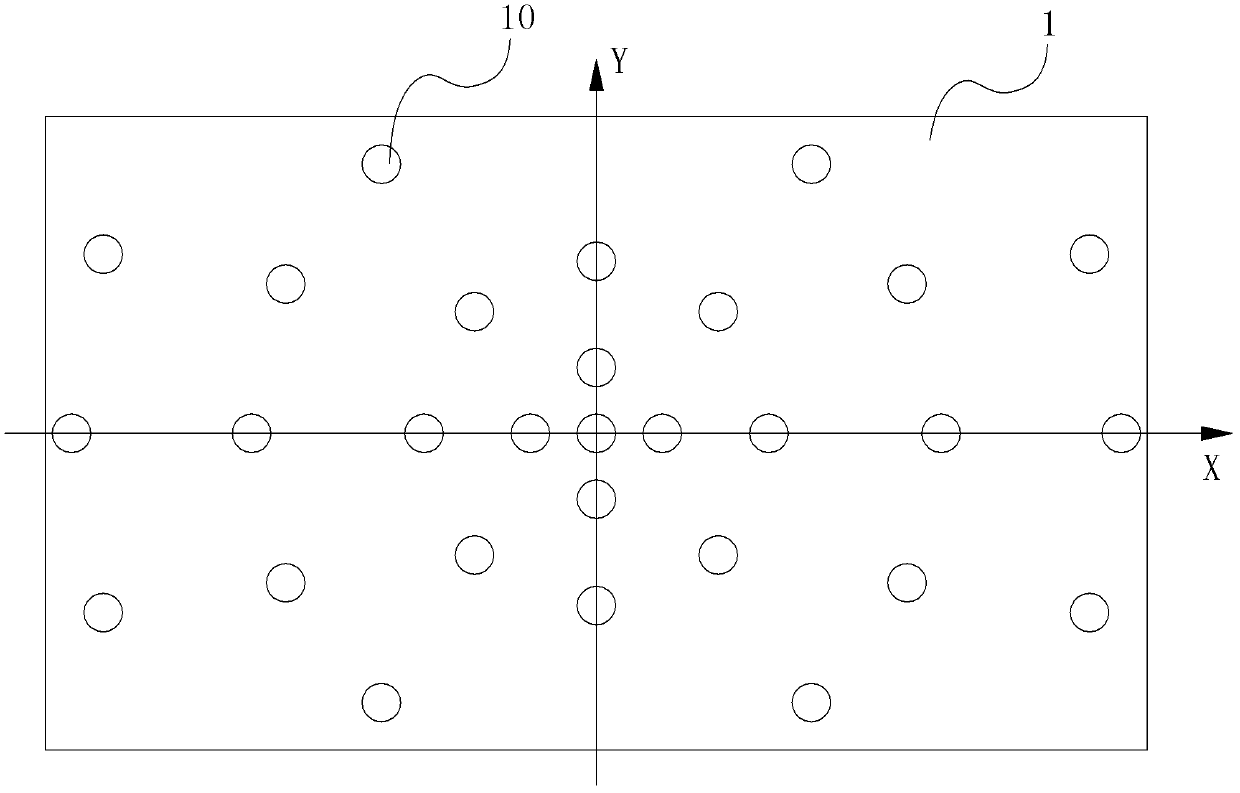

[0036] Such as figure 2 As shown, the direct-lit backlight for liquid crystal display in this example includes a substrate 1 and LEDs 10 mounted on the substrate 1 . In this example, the distribution of LEDs 10 on the substrate 1 is dense in the middle and sparse in the periphery. The area where the intersection of the horizontal axis X and the vertical axis Y of the substrate 1 is located is the central area of the substrate 1 , and the distribution density of LEDs 10 in this area is greater than that of the peripheral area of the substrate 1 . In addition, the distribution of the LEDs 10 in this example takes the horizontal axis X as the symmetrical axis and the vertical axis Y as the symmetrical axis. and figure 1 Comparing the uniform distribution methods shown, it can be seen that the reduction of the usage of LED 10 is very obvious.

Embodiment 2

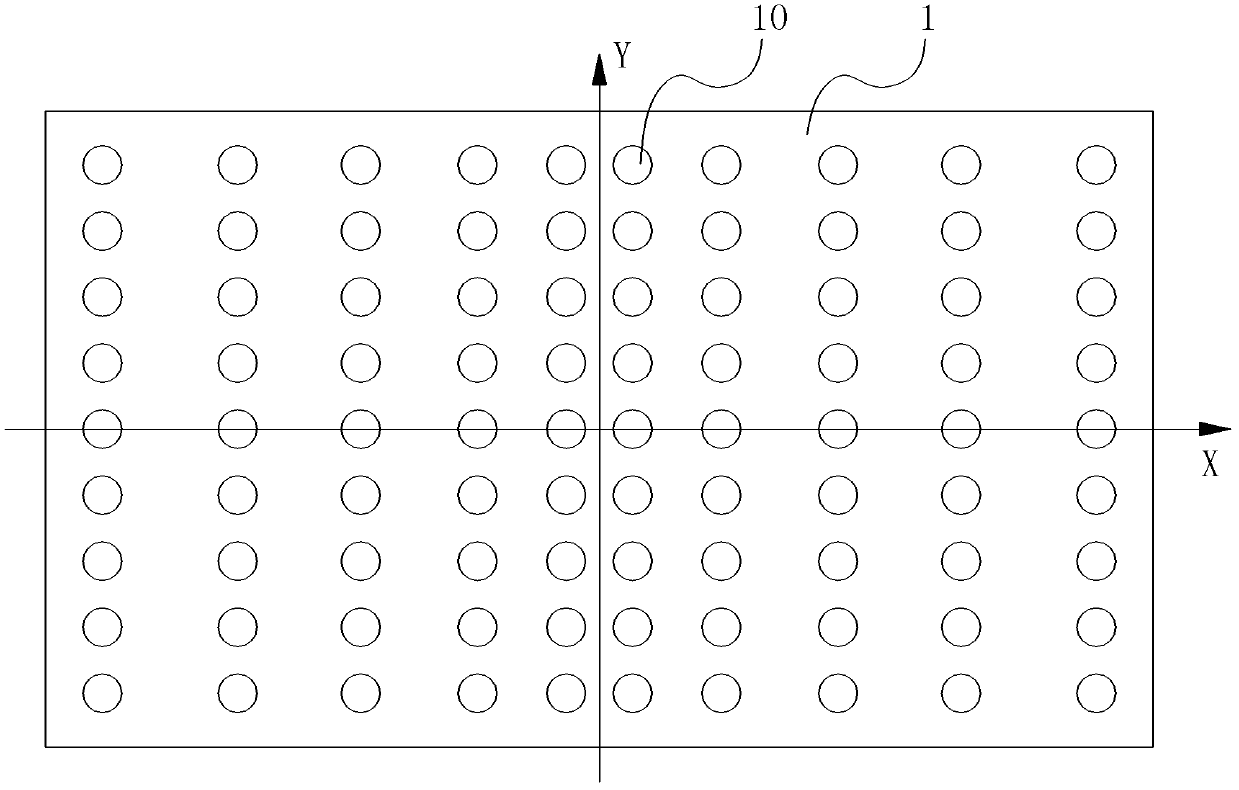

[0038] In this example, the direct-lit backlight of the liquid crystal display screen, the distribution of LED10 on the substrate 1 is as follows: image 3 As shown, the LEDs 10 are arranged in N rows and M columns, where N=9 and M=10 in this example. image 3 , the row spacing of the LED10 arrangement remains unchanged, and the column spacing increases from the central area of the substrate to the peripheral area of the substrate, that is image 3 From the area where the vertical axis (Y axis) is located, the column spacing is along the X direction and the -X direction ( image 3 in the left and right directions) gradually increase. In this distribution mode, the distribution of LEDs is symmetrical, and the X-axis and Y-axis are their symmetry axes. In this example, the LEDs can be packaged into LED light strips first, and each LED light strip has the same structure, the number of LEDs is equal (9 pieces), and the spacing is the same, which is convenient for standardize...

Embodiment 3

[0040] Such as Figure 4 As shown, in this example, the direct-lit backlight of the liquid crystal display screen, the LEDs 10 are also arranged in N rows and M columns on the substrate 1, where N=7 and M=16 in this example. Figure 4 , the column spacing of the LED10 array remains unchanged, and the row spacing increases from the central area of the substrate to the peripheral area of the substrate, that is Figure 4 From the area where the horizontal axis (X axis) is located, the line spacing is along the Y direction and the -Y direction ( Figure 4in the upper and lower directions) gradually increase. In the distribution mode of this solution, the distribution of LEDs is symmetrical, and the X-axis and Y-axis are their symmetry axes. In this example, LEDs can be packaged into LED light strips first, and each LED light strip has the same structure, the number of LEDs is equal (16 pieces), and the spacing is the same, which is convenient for standardized production. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com