A high-speed rotor and a control moment gyroscope using the rotor

A high-speed rotor and housing technology, applied in the direction of rotating gyroscope, etc., can solve the problem of narrow temperature range, and achieve the effect of solving the narrow temperature range and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

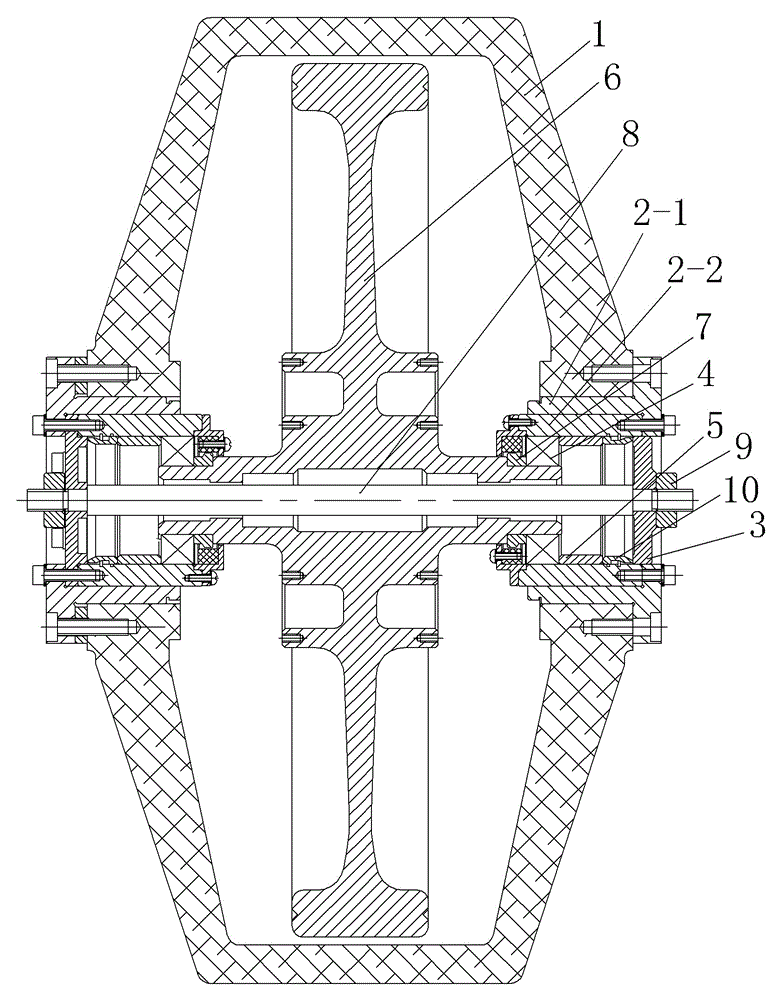

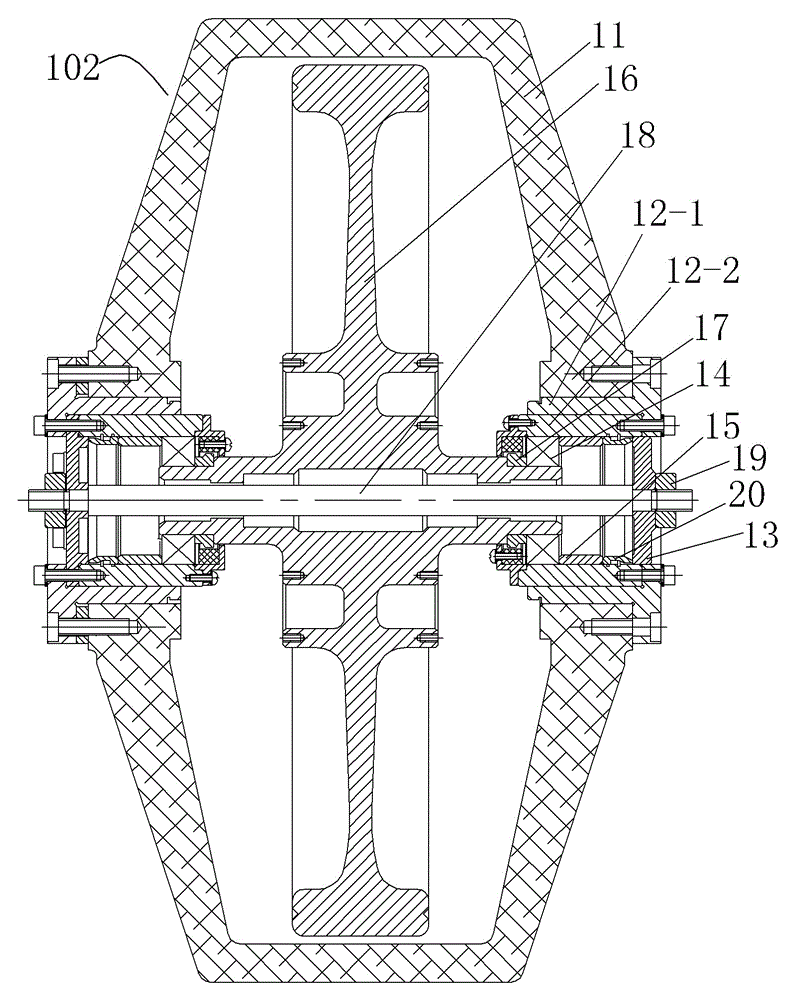

[0014] Example 1 of a high-speed rotor, such as figure 1 As shown, there is a housing 1, the housing 1 is equipped with bearing seats on opposite sides respectively, and the two bearing seats are connected to the outer cylinder 2-1 on the housing by flanges and coaxially fixedly assembled on the outer cylinder 2- 1 is composed of a core tube 2-2, and the outer ends of the core tubes 2-2 of each bearing seat are connected with the inversion edge bolts at the outer end of the outer tube; the two bearing seats are respectively provided with bearing glands 3 at the outer ends, Angular contact ball bearings 4 are installed inside, and the two angular contact ball bearings 4 located in the two bearing seats are arranged opposite to each other. The respective outer rings of the two angular contact ball bearings 4 respectively pass through the loading rings arranged between them and the corresponding bearing glands. 5 and the disc spring 10 are tightened so that the two angular contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com