Reverse cover screening system

A cover and reverse technology, which is applied in the direction of optical testing for defects/defects, etc., can solve the problems of inconspicuous differences on the surface of the cover, fluctuations in the characteristics of the solder on the surface of the cover, and affecting product quality, so as to ensure screening efficiency and product quality, and improve Recognition ability and screening efficiency, effect of improving recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

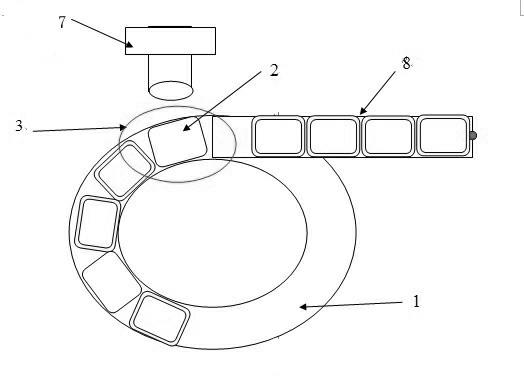

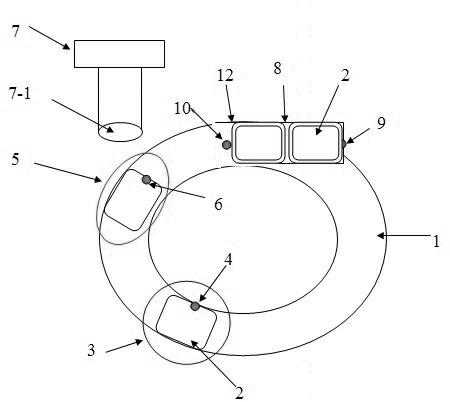

[0013] See figure 2 , the present invention comprises a vibrating plate, a circular track 1 is arranged on the vibrating plate, a cover 2 is placed on the circular track 1, the initial position on the circular track 1 and the cover 2 is placed on it is set as a pre-screening area 3, Set the first sensor 4 in the pre-screening area 3, the first sensor 4 is a high-sensitivity optical fiber digital display sensor (Keyence fiber optic sensor), the first sensor 4 is located inside the circular track 1 and on the edge of the cover 2 , the cover 2 centrifugally vibrates with the circular track 1, a second sensor 6 is set at the middle position 5 of the circular track 1, the second sensor 6 is an external trigger sensor of the optical recognition system, and the second sensor 6 is located on the edge of the cover, The optical recognition system 7 is located above the position 5 in the middle of the circular track, and picks up the front of the track 8. Its optical lens 7-1 faces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com