Lathe center frame

A technology of center frame and lathe, which is applied in the direction of turning equipment, large fixed members, auxiliary devices, etc. It can solve the problems of easy wear and tear of jaws, achieve the effect of reducing cost consumption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

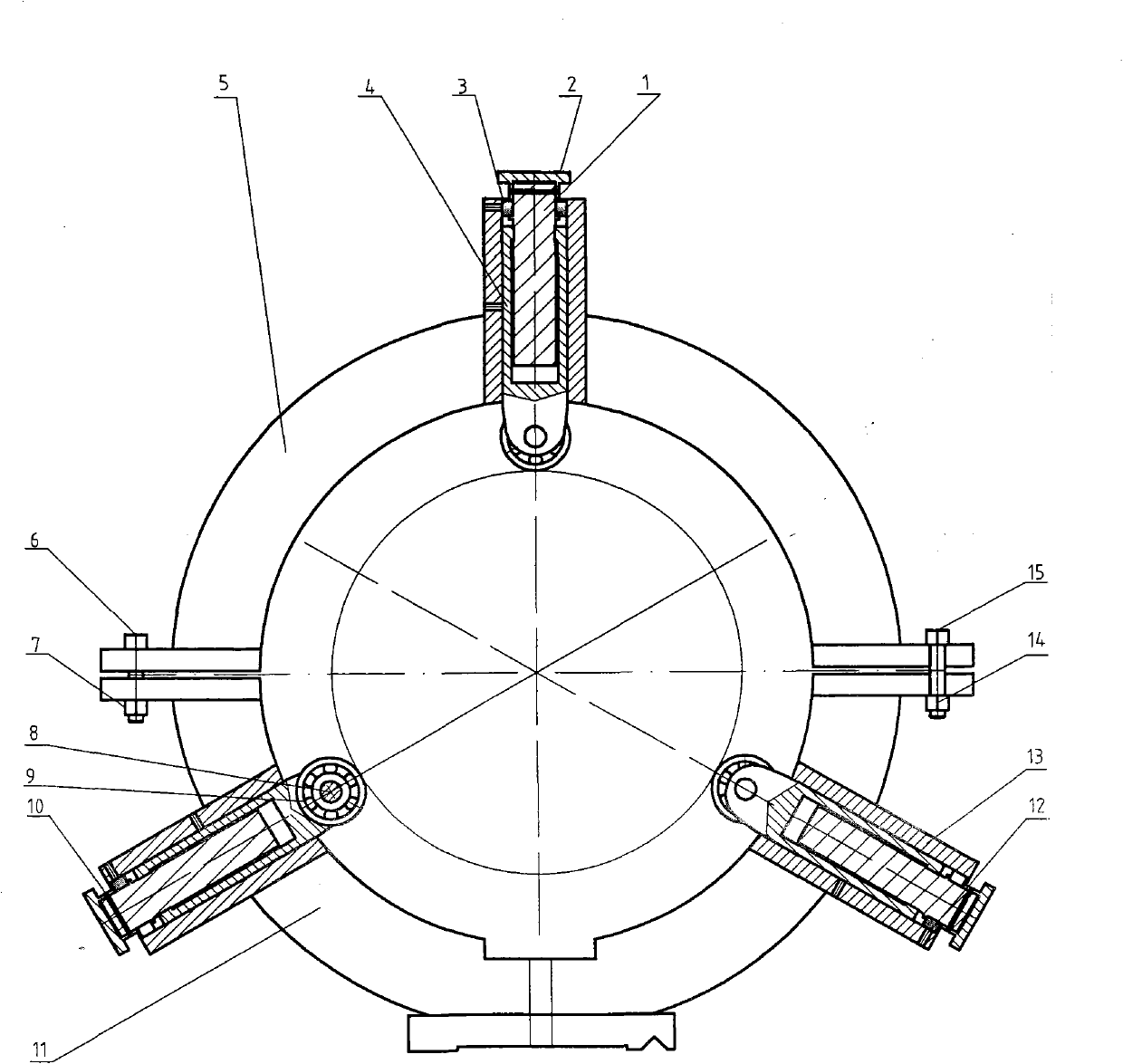

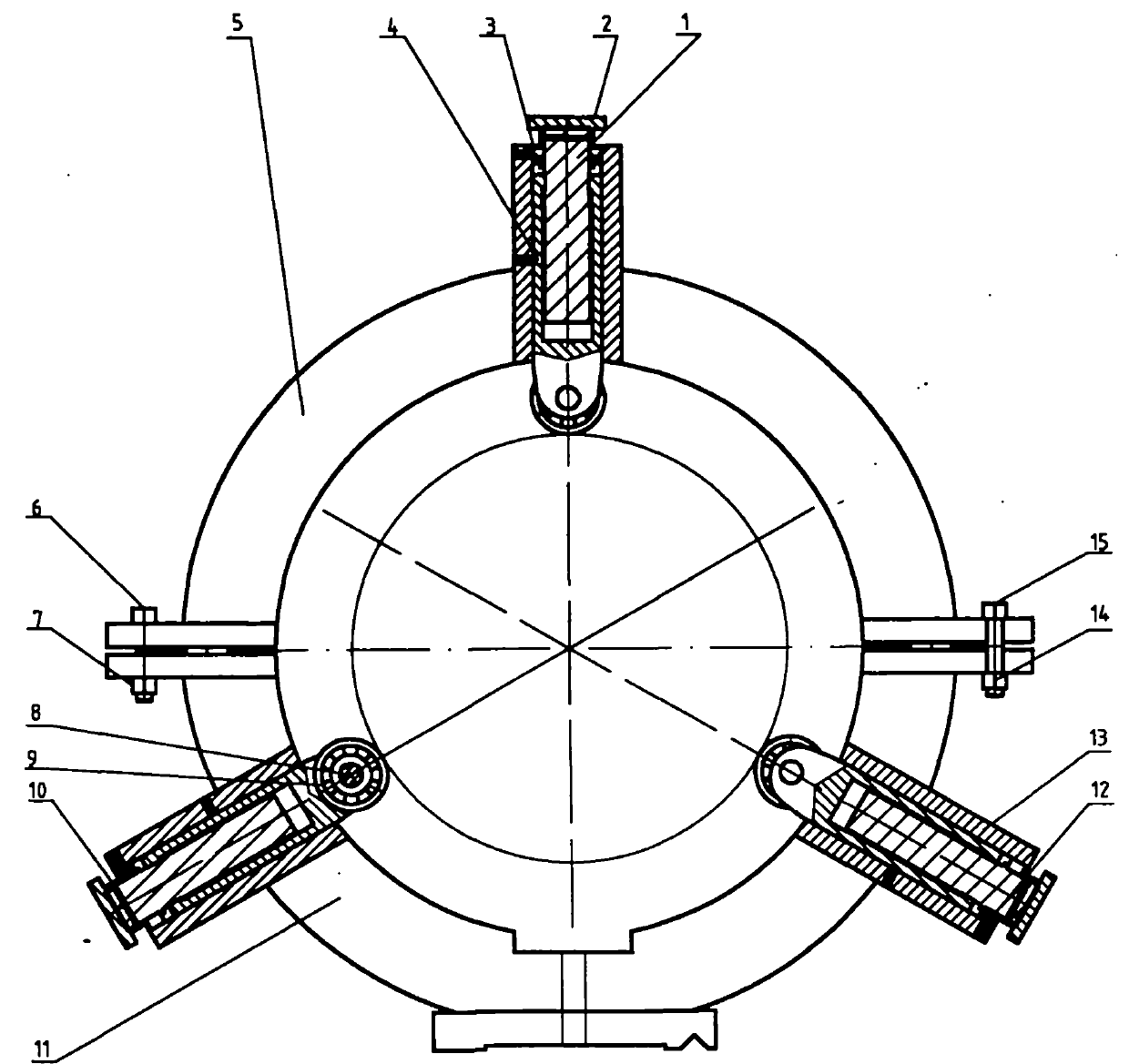

[0012] As shown in the figure, the center screw (1) is screwed into the jaw (4), the upper end of the center screw (1) is covered with the screw fixing sleeve (3), the center screw (1) and the screw adjusting screw sleeve ( 2) Fix it with the fixing pin (10), and put the combination of the central screw rod (1), jaws (4), screw adjusting screw sleeve (2) and screw fixing sleeve (3) into the clamping jaw fixing sleeve ( 13), the screw mandrel fixing sleeve (3) is fixed in the fixing sleeve (13) by the jaw fixing pin (12). The movable frame (5) and the fixed frame (11) are fixed by bolts (6), nuts (7), bolts (15), and nuts (14). The jaws (4) are in contact with the workpiece, and the radial ball bearing rotates around the center of the workpiece under the action of the cutting force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com