Glass rib clamp

A technology of glass ribs and fixtures, applied to building components, walls, buildings, etc., can solve problems such as high safety performance requirements, wind pressure, deformation and instability, and achieve the effects of high safety, enhanced strength, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

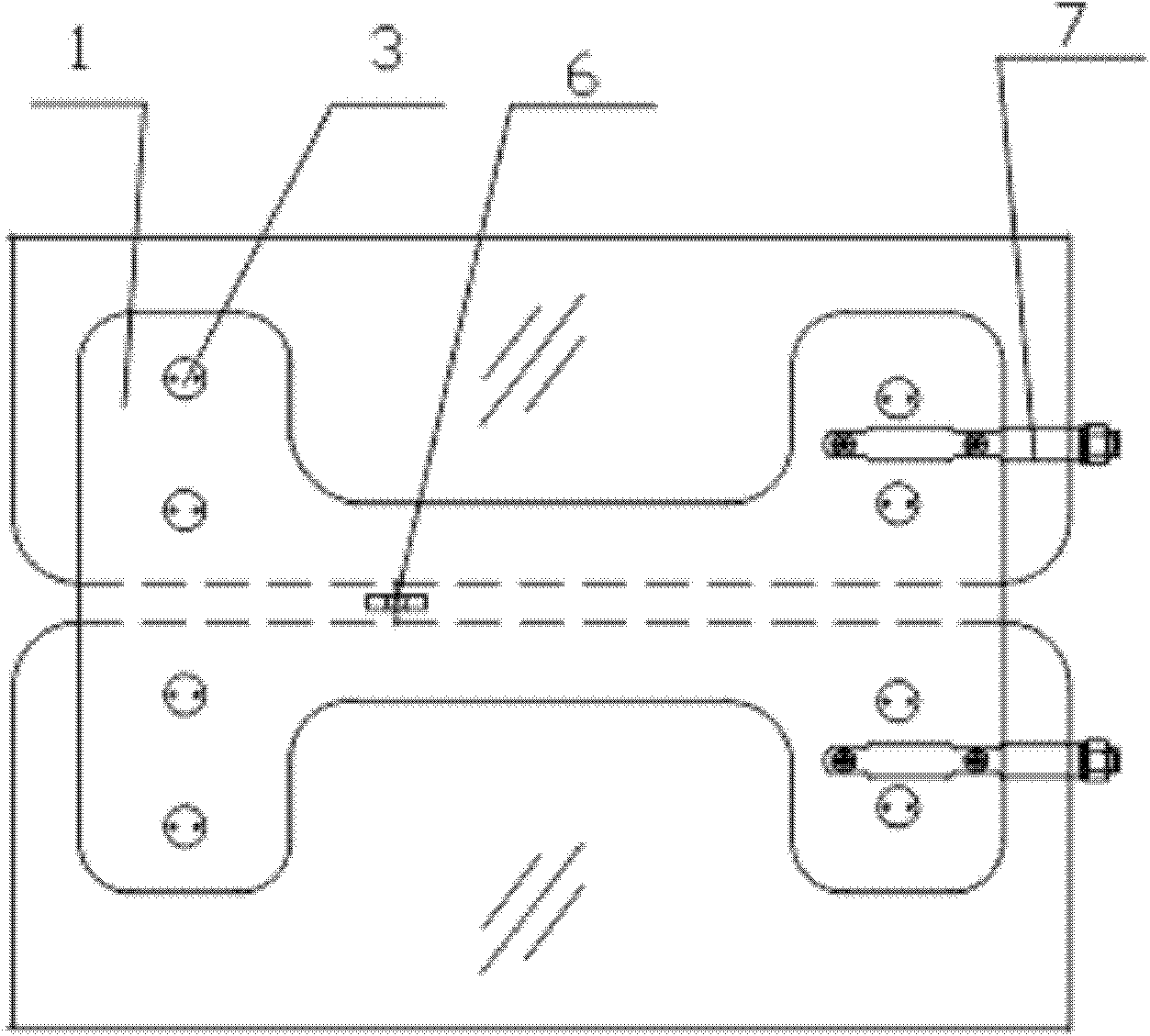

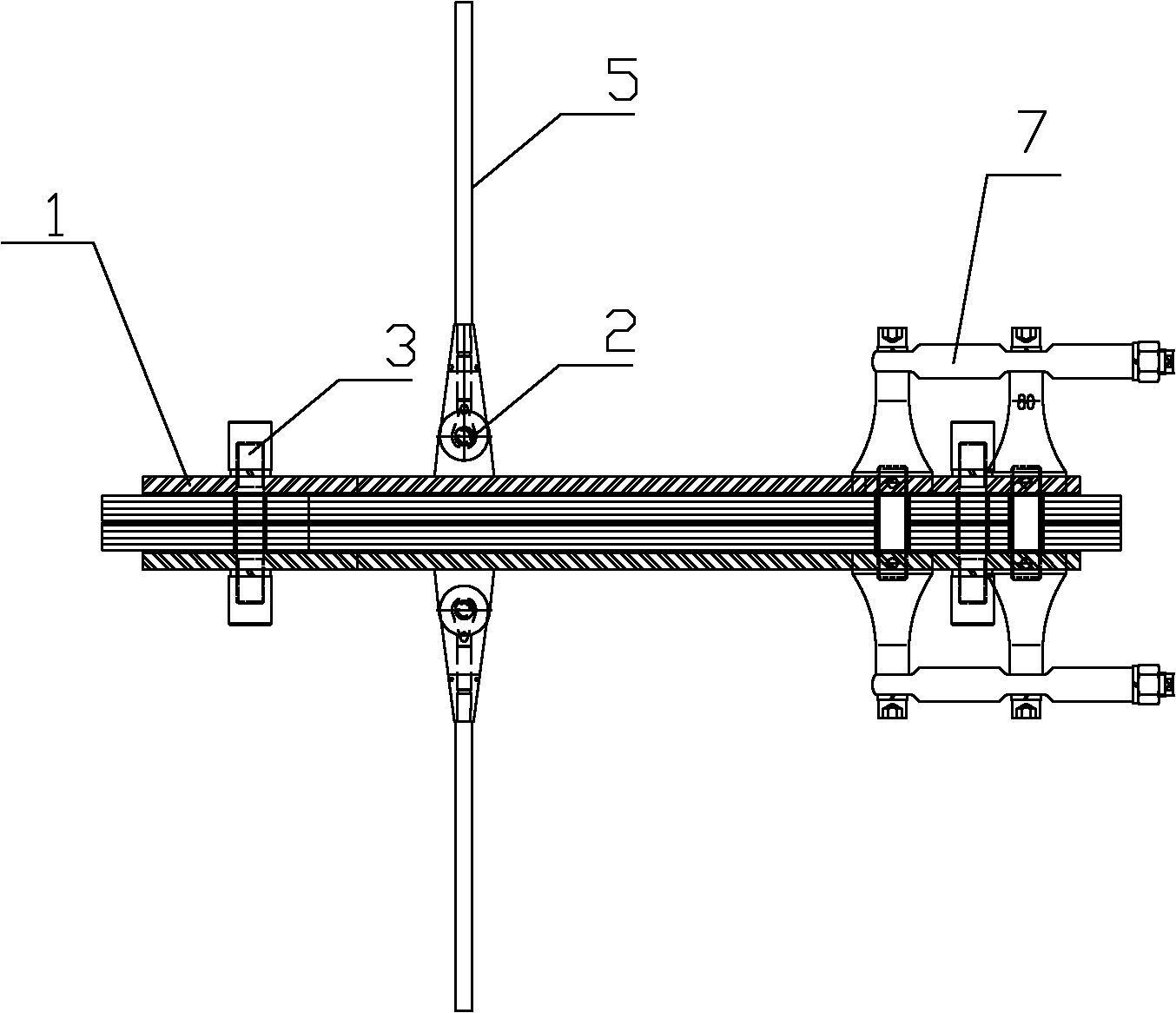

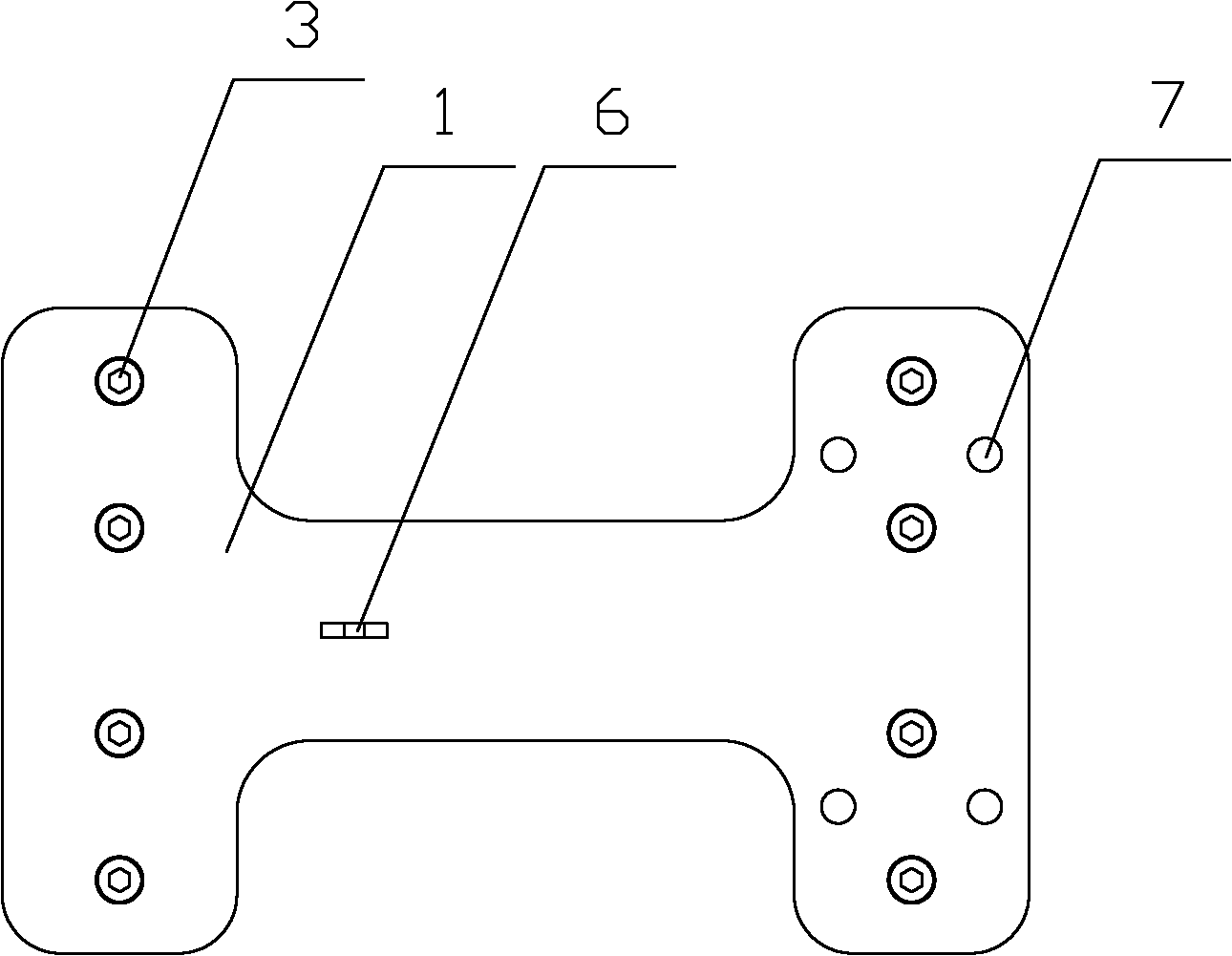

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the glass rib clamp includes a glass rib splint 1 and an ear plate 2. The glass rib splint 1 is composed of two "H" shaped stainless steel plates overlapped and connected, and the glass rib splint 1 is installed vertically. This shape is more conducive to overcoming The stress of the glass can increase the strength of the glass ribs and make the curtain wall structure more stable; the thickness of the stainless steel plate is 2-12mm, and its material is made of 316 stainless steel. The glass rib splint 1 is provided with a vertical row of connecting studs 3, and the connecting studs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap