Hydraulic support and top beam thereof

A technology of hydraulic supports and roof beams, which is applied to support the roof beams of mine roofs, mining equipment, earthwork drilling and mining, etc. It can solve the problems of time-consuming manufacturing process, poor mechanical performance, and increased weight of roof beams, etc., to achieve Improve production efficiency, ensure mechanical properties, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

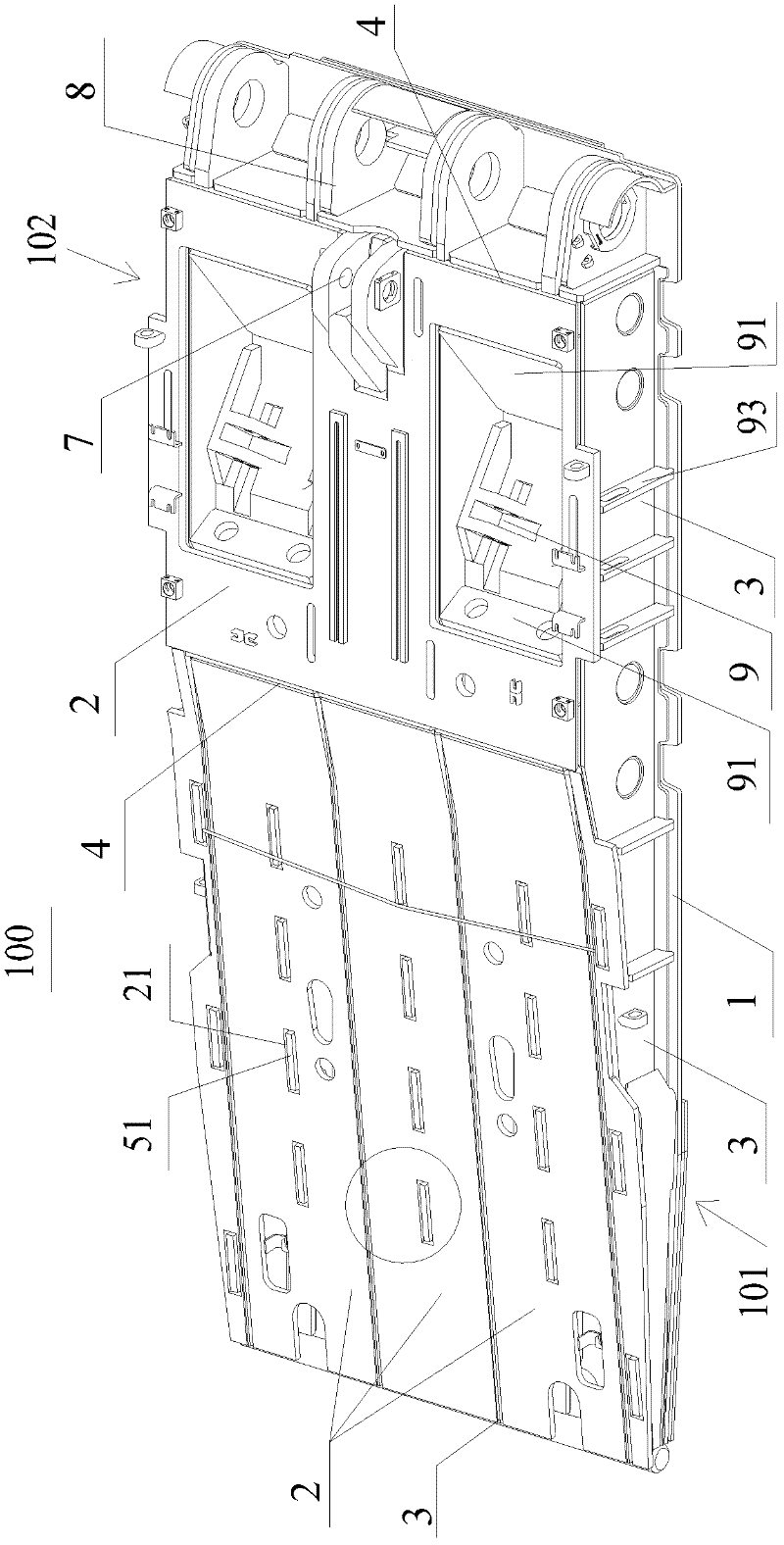

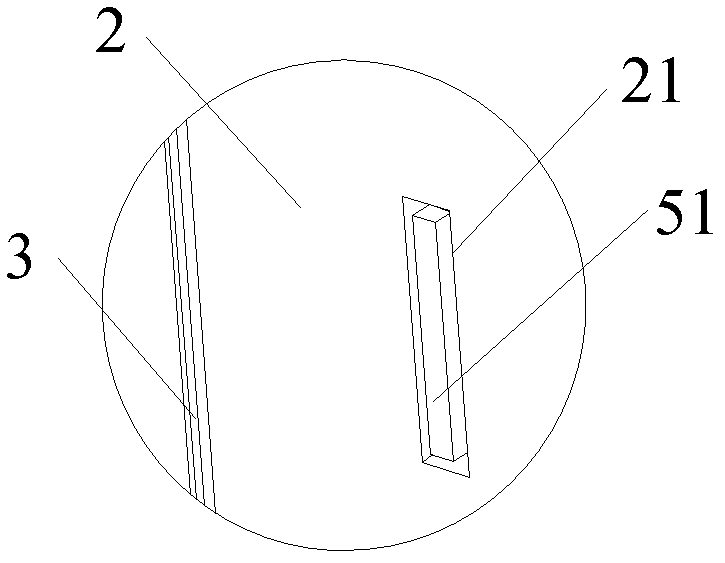

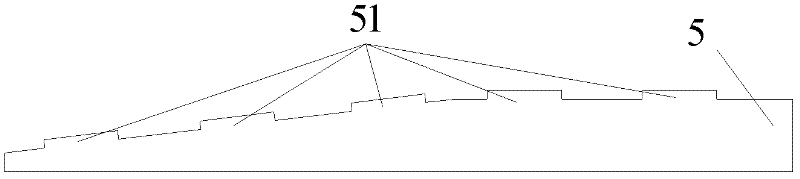

[0025] see figure 1 , shows a preferred structure of the top beam of a hydraulic support provided by the present invention, as shown in the figure, the top beam 100 of the hydraulic support at least includes a top plate 1, a cover plate 2, and is connected between the top plate 1 and the cover plate 2 And longitudinally run through a plurality of longitudinal main ribs 3 at the front and rear of the entire top beam.

[0026] The rear part of the top beam 100 is usually provided with a plurality of transverse ribs 4 perpendicular to the longitudinal main ribs, and the transverse ribs 4 , the longitudinal main ribs 3 , the top plate 1 and the cover plate 2 form a box structure part 102 . In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com