Automatic plate wrapping machine for lead accumulator

A technology of lead-acid battery and wrapping machine, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. It can solve the problems of personal health damage, more plate contact, low work efficiency, etc., and achieve improvement Production efficiency, high degree of automation, and the effect of reducing heavy metal contact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

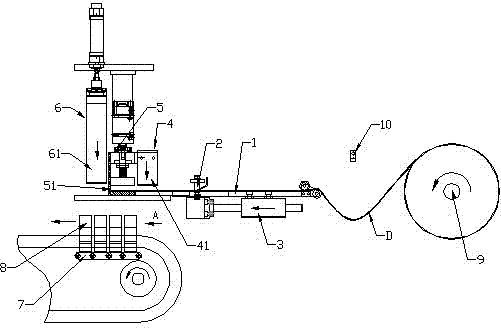

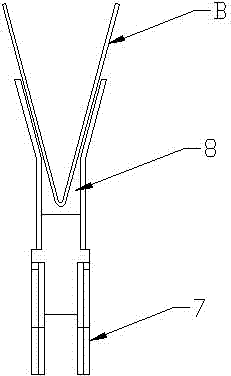

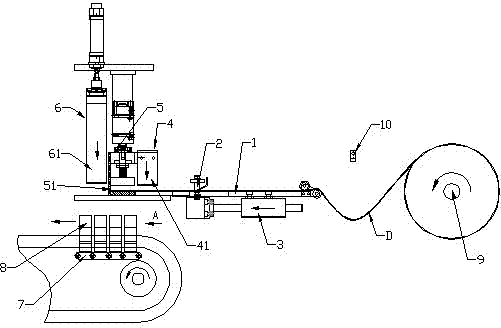

[0011] As shown in the figure, the lead-acid battery automatic packing machine includes a workbench 1, on which a feeding rail for strip-shaped separator material D to move longitudinally; The material clamping mechanism 2, the material clamping mechanism is driven by the feeding cylinder 3 arranged on the side of the workbench to move forward and backward in the longitudinal direction, so as to realize the gradual forward feeding of the strip-shaped partition material; the front section of the workbench 1 is from back to front The indentation mechanism 4, which can press the longitudinal indentation in the center of the separator material, and the cutting mechanism 5, which can cut the front-end separator material to form a single-piece battery separator, can be arranged in turn. Folding material folding mechanism 6; The material folding mechanism 6 includes a top plate 61 that can be vertically raised and lowered above the front end of the workbench. There is a feeding troug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com