Method for producing wafer lens, and method and apparatus for producing wafer lens laminate

A technology of a wafer lens and a manufacturing method, which is applied in the directions of lenses, applications, instruments, etc., can solve the problems of not obtaining optical characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

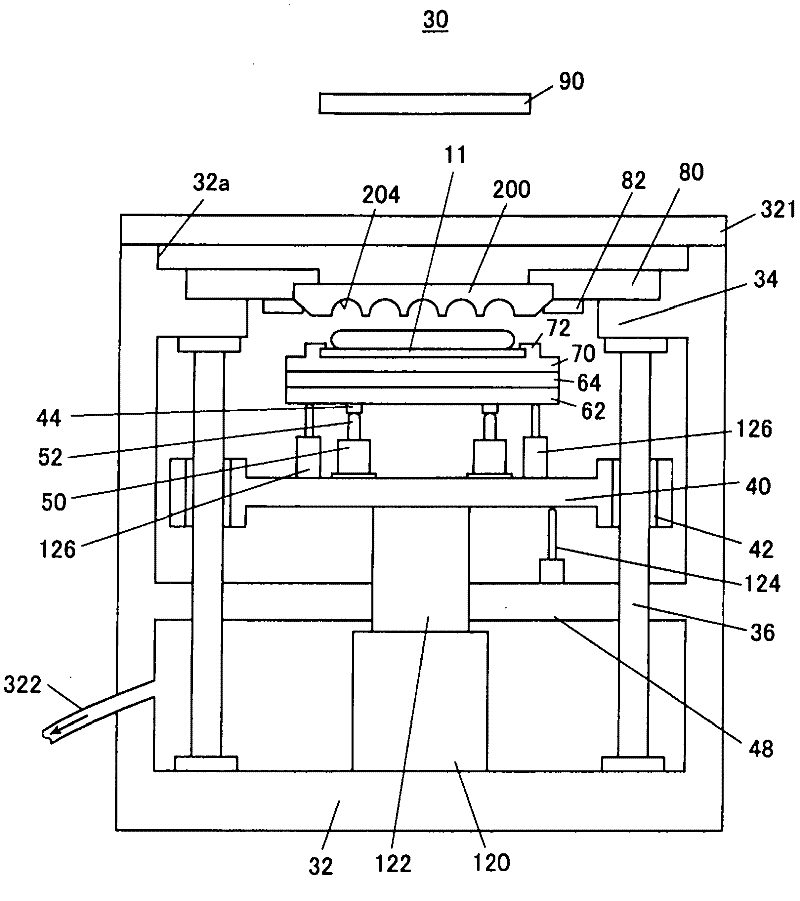

[0053] Preferred embodiments of the present invention will be described below with reference to the drawings.

[0054] [Wafer lens, wafer lens aggregate, wafer lens laminate]

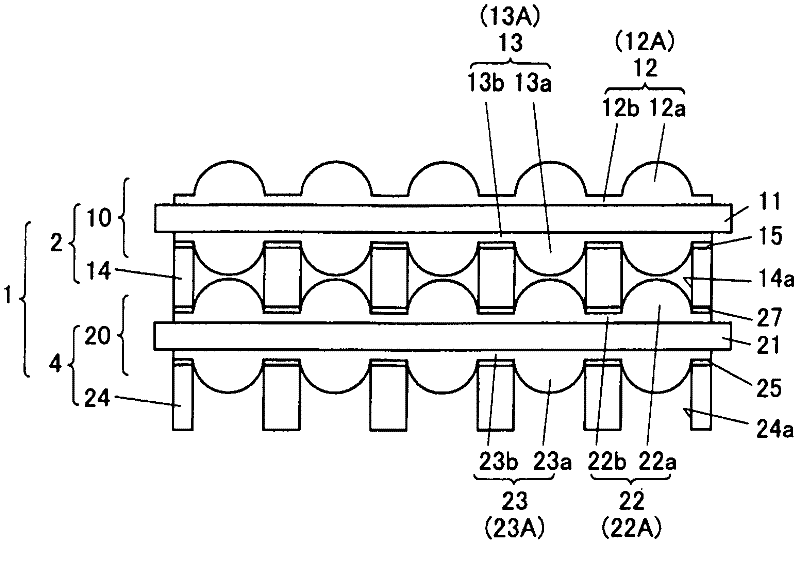

[0055] Such as figure 1 As shown, the wafer lens laminate 1 has a structure in which wafer lens aggregates 2 and 4 are stacked up and down, and the wafer lens aggregate 2 and the wafer lens aggregate 4 are bonded with an adhesive 27 .

[0056] The wafer lens aggregate 2 includes: a wafer lens 10 ; and a glass spacer 14 for maintaining a certain distance from the wafer lens 20 .

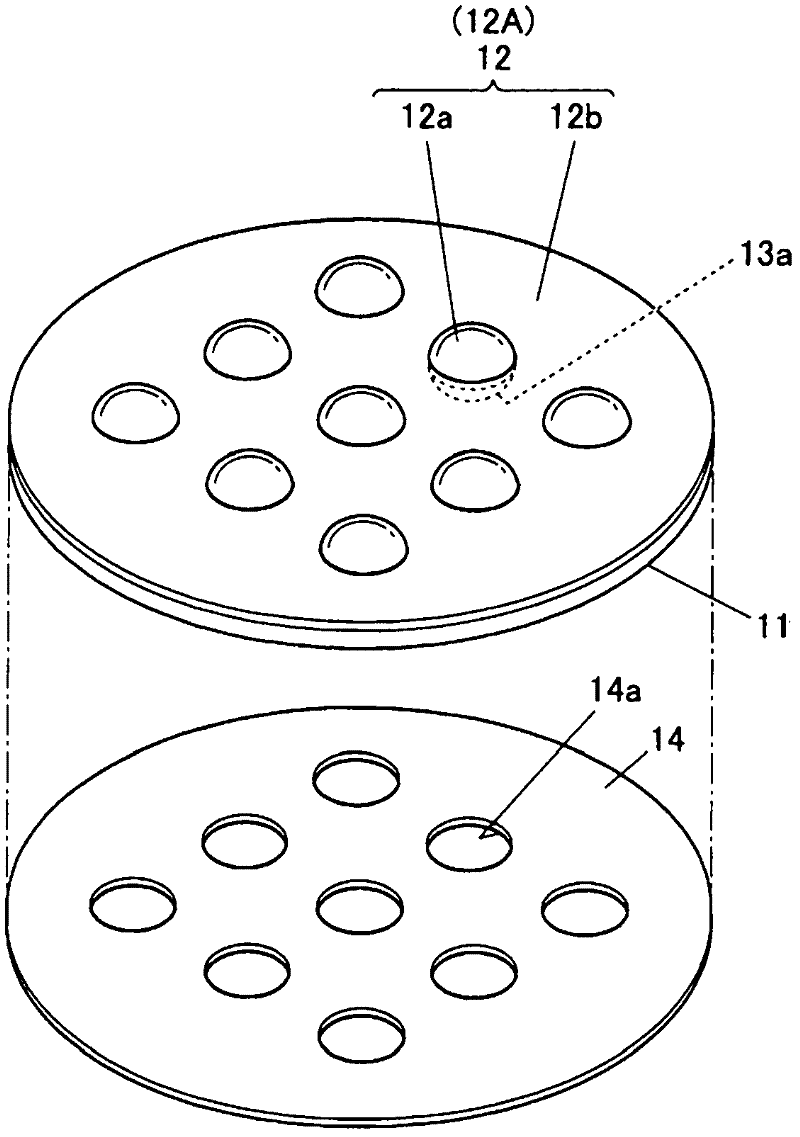

[0057] The wafer lens 10 includes: a circular glass substrate 11; and resin portions 12, 13 formed on the upper and lower surfaces of the glass substrate 11, respectively.

[0058] A resin portion 12 is formed on the upper surface of the glass substrate 11 . The resin portion 12 includes: convex lens portions 12a constituting an optical surface; and non-lens portions 12b formed between the convex lens portions 12a.

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com