Rod placing device

A bar and bar technology, applied in the field of bar placement devices, can solve the problems of high labor intensity and low work efficiency of workers, and achieve the effects of simple structure, satisfying configuration requirements, and realizing process mechanization and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

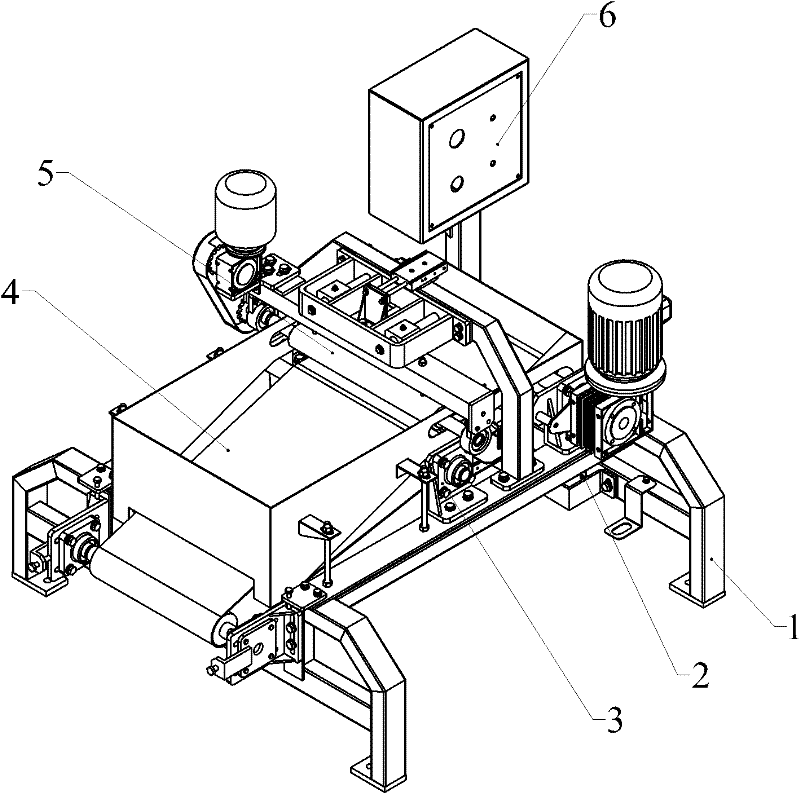

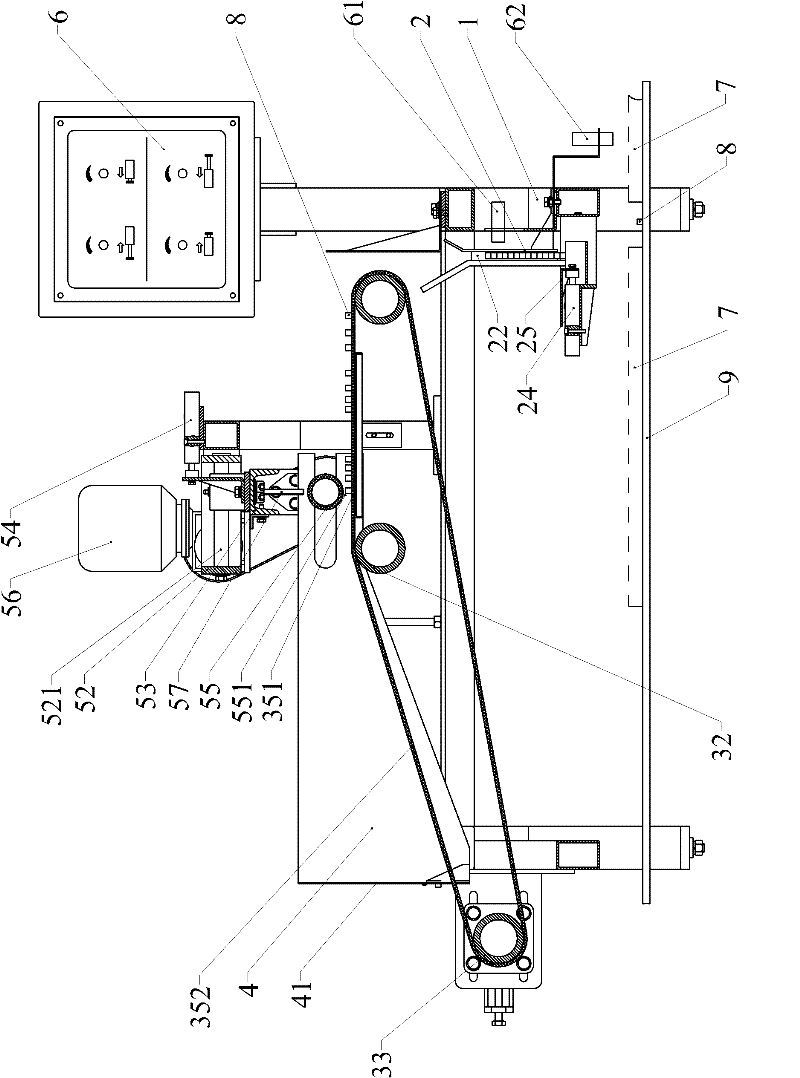

[0025] like Figure 2 to Figure 7 As shown, a rod placing device according to the present invention is tied to a frame 1 to set a rod blanking mechanism 2, a rod conveying mechanism 3, a feed bin 4, a lever mechanism 5 and an electric control device 6.

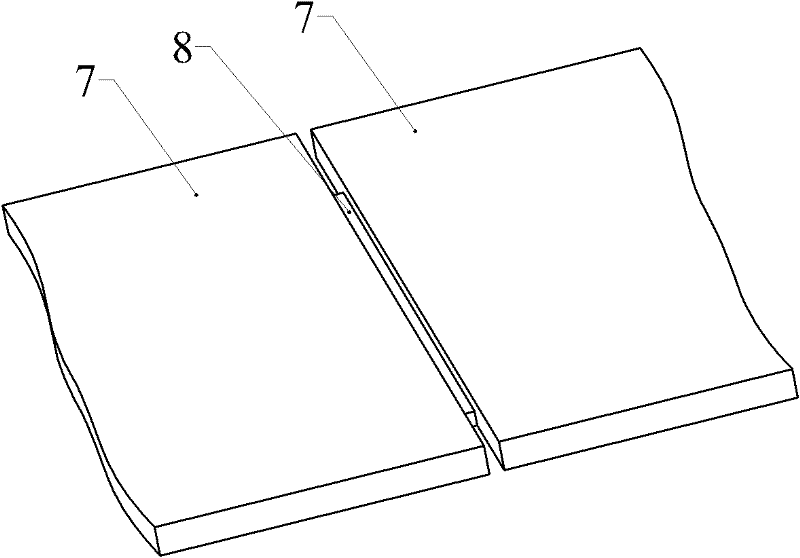

[0026] like image 3 , Image 6 and Figure 7 As shown, the bar blanking mechanism 2 includes a vertically arranged first bar 211 and a second bar 212, wherein the first bar 211 is connected to the frame 1 through a fixed connection, and the second bar The bar 212 is connected with the frame 1 in an adjustable manner. The gap between the two bars forms a bar channel 22, because the second bar 21 is adjustable, so the width S1 of the bar channel 22 is also adjustable, and the width S1 should be greater than or equal to the width of a bar and less The width of the two rods is preferably slightly wider than the width of one rod by 1-2mm. Therefore, the rods 8 placed in the rod channel 22 are stacked single from bottom to top....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com