Air channel ignition system and ignition burner under bed

An under-bed ignition and burner technology, applied in the direction of burners, fluidized bed combustion equipment, burners burning powder fuel, etc., can solve the problems of fuel waste, cumbersome debugging process, oil dripping, etc., and achieve simplified start-up and The effect of debugging process, reducing fuel consumption and avoiding fuel waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

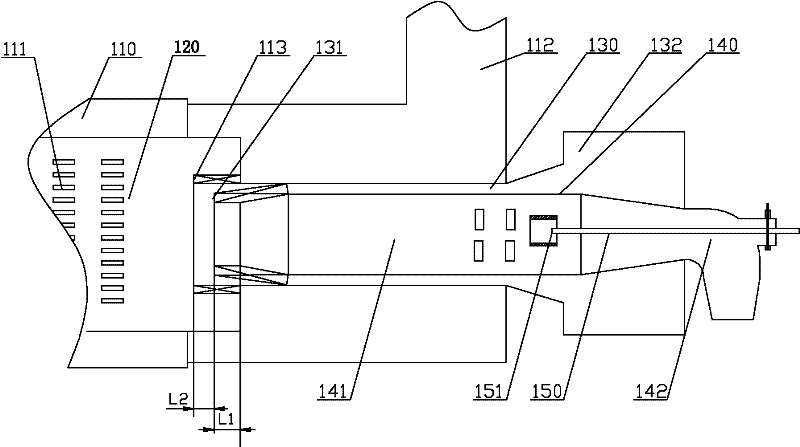

[0037] Please refer to figure 2 , which is a schematic structural diagram of an under-bed ignition burner provided in Embodiment 1 of the present invention. The under-bed ignition burner includes a supplementary air passage 110, a combustion air duct 120 and an air distribution duct 130; The duct 110 communicates with a predetermined air source through the supplementary air opening 112 . The rear end of the air distribution channel 130 forms a peripheral air nozzle 131 which communicates with the front end of the combustion air channel 120 , and the front part of the air distribution channel 130 communicates with a predetermined air source through an air distribution port 132 . In addition, the under-bed ignition burner also includes a burner body 140 and an ignition device 150 . The burner body 140 includes an internal combustion section 141; the front end of the internal combustion section 141 communicates with a predetermined pulverized coal passage (not shown in the fig...

Embodiment 2

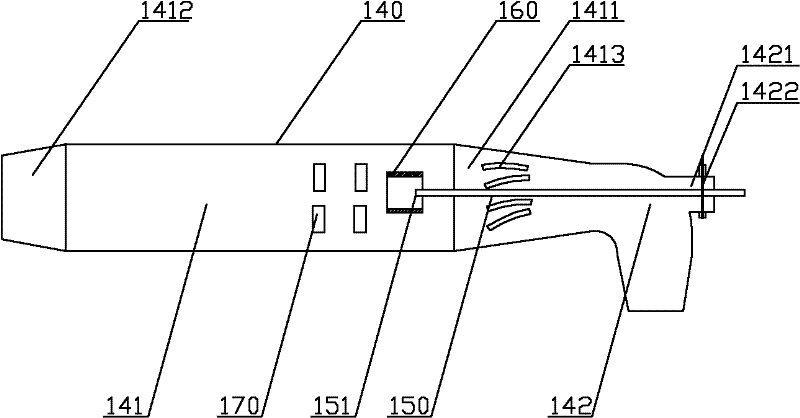

[0052] Please refer to Figure 4 , which is a schematic structural diagram of the under-bed ignition burner provided in Embodiment 2 of the present invention. Compared with Embodiment 1, the difference lies in that: the ignition device 150 is an oil gun assembly that consumes fuel; the oil gun assembly includes an oil gun and an air distributor used in conjunction with the oil gun. The ignition end formed by the oil gun assembly extends into the front end of the internal combustion section 141 . Same as the first embodiment, the oil gun assembly is movably installed in the burner body. Such as Figure 5As shown, this figure is a structural schematic diagram of another state of the under-bed ignition burner provided by Embodiment 2 of the present invention. When the ignition device 150 is an oil gun assembly, when there is a problem with the pulverized coal supply or other circumstances, the ignition device under the bed can be easily changed so that the oil gun assembly can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com