Contact exposure method and contact exposure apparatus

An exposure method and an exposure device technology, which are applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve problems such as inability to eliminate misalignment and non-convergence of calibration, and achieve rapid alignment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

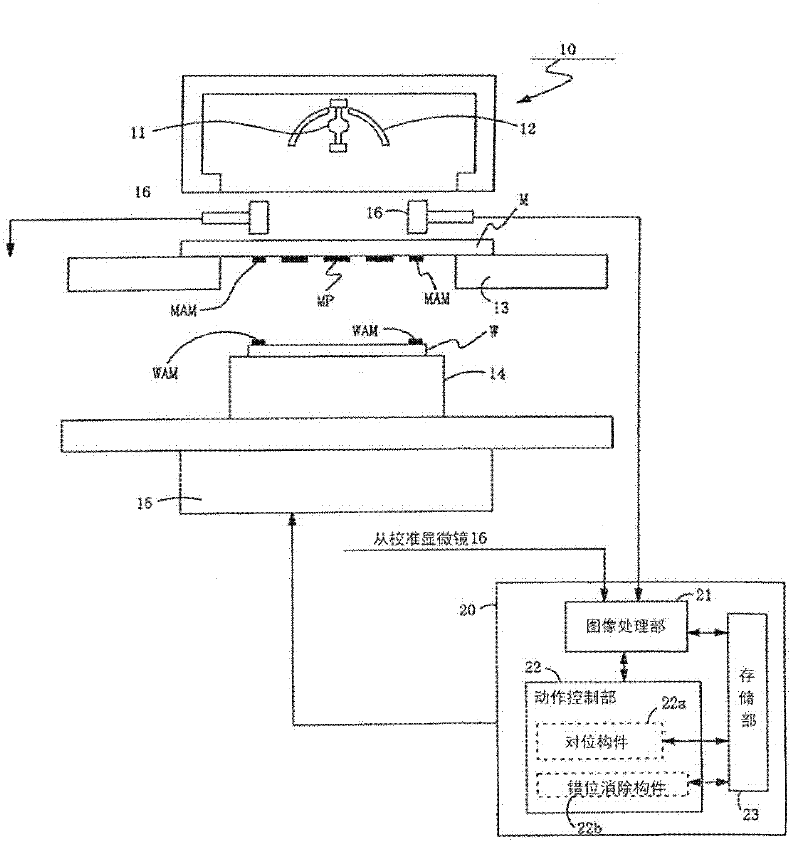

[0073] figure 1 It is a figure which shows the structure of the contact exposure apparatus of the Example of this invention, This figure is a cross-sectional view of an apparatus.

[0074] In this figure, for the above Figure 7 The same components are assigned the same symbols, and the contact exposure apparatus of this embodiment includes: a light irradiation unit 10 that emits exposure light; a mask stage 13 that holds a mask M; and a workpiece that holds a workpiece W to be exposed. Taiwan 14.

[0075] The light irradiation unit 10 includes a lamp 11 that emits light including exposure light, and a mirror 12 that reflects the light emitted from the lamp 11 . The mask stage 13 holds the mask M on which the pattern (mask pattern) MP is formed by vacuum suction or the like.

[0076] The work stage 14 holds the work W onto which the mask pattern MP is transferred. A work table driving mechanism 15 is attached to the work table 14 . The workpiece table driving mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com