Working liquid and device utilizing same

An in-device, working fluid technology, used in transmission, fluid transmission, petroleum industry, etc., can solve problems such as corrosion and abnormal noise, and achieve the effect of suppressing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

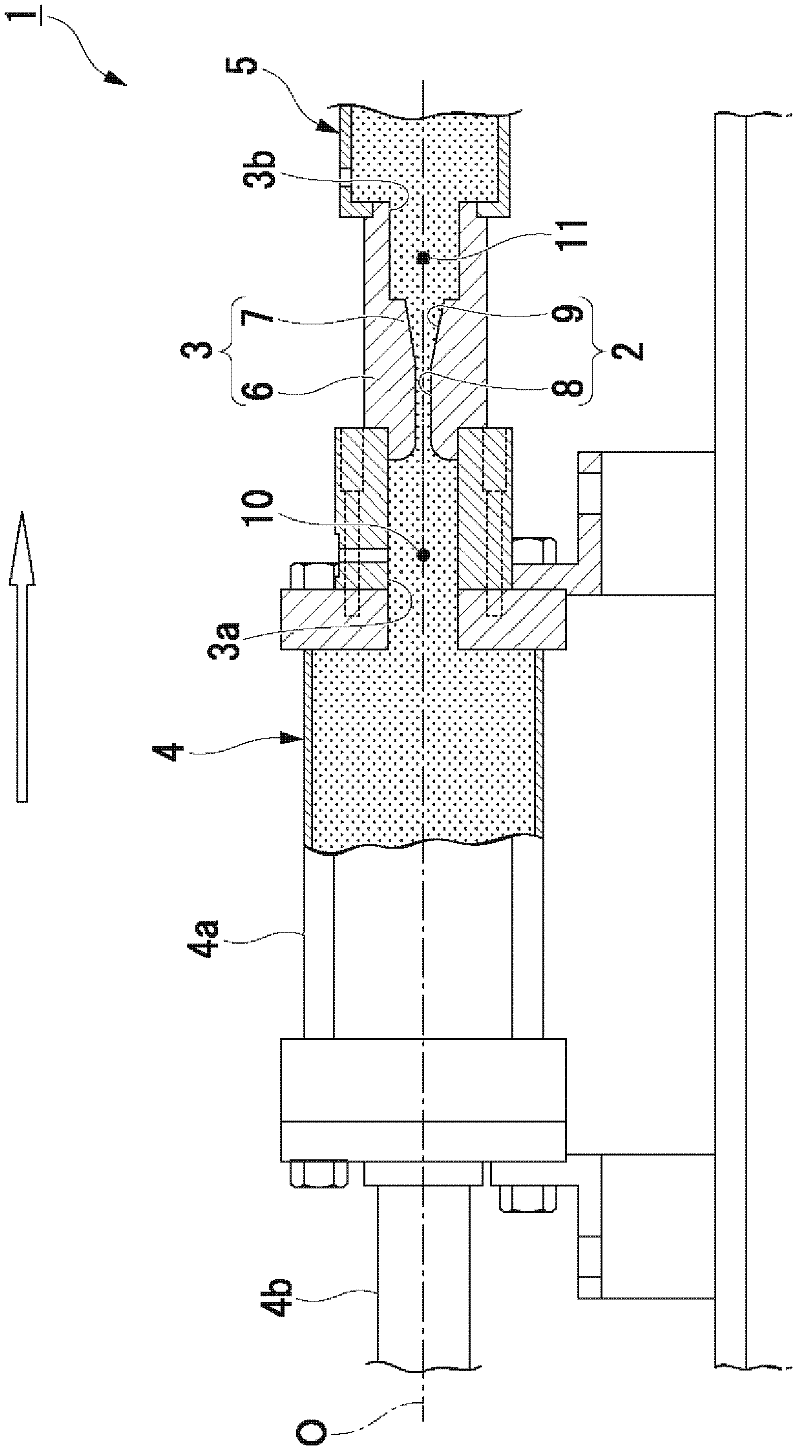

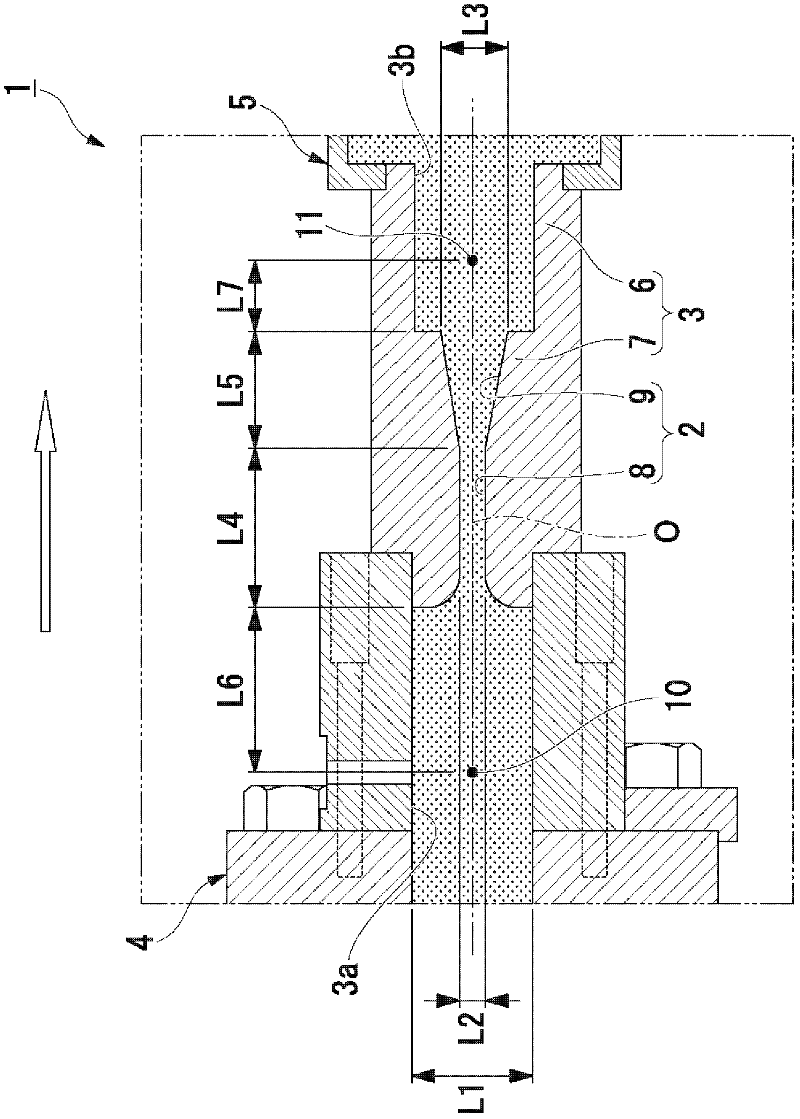

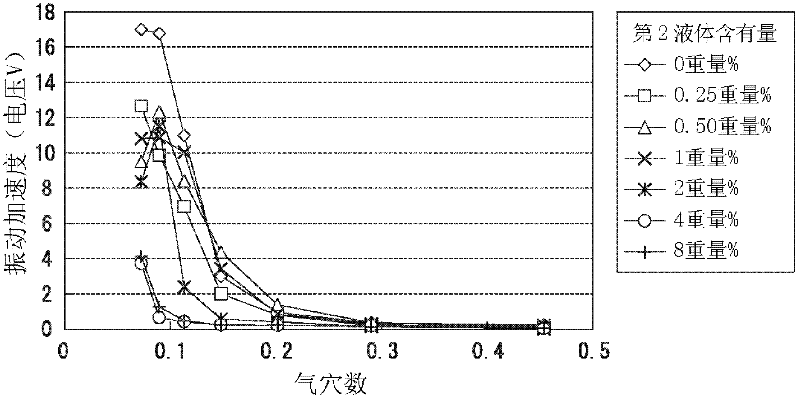

[0029] A working fluid according to one embodiment of the present invention will be described below.

[0030] The working fluid of the present embodiment is used by being sealed in the liquid sealing space in the device. In addition, the working fluid of the present embodiment plays a role of transferring energy such as kinetic energy or thermal energy in the device, absorbing and weakening a load applied from the outside of the device, and the like, for example. And, in the device in which the working fluid is sealed in the liquid sealing space, the function required for the device is exhibited based on the above-mentioned action of the working fluid.

[0031] This working fluid is suitable for the following cases, etc.: For example, working oil sealed in an ink pressurizing mechanism of an inkjet printer, various hydraulic devices, etc., and flowing inside the device to transmit kinetic energy; sealing a liquid crystal for cooling a liquid crystal projector; Heat medium (su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com