Bacillus thuringiensis liquid fermentation culture medium as well as bacterium powder and oil suspension thereof

A technology of Bacillus thuringiensis and liquid fermentation, applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of further reduction in particle size, poor suspension stability, and adverse effects of organic agricultural production, and achieve physical and chemical Stable properties and biological activity, low production cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

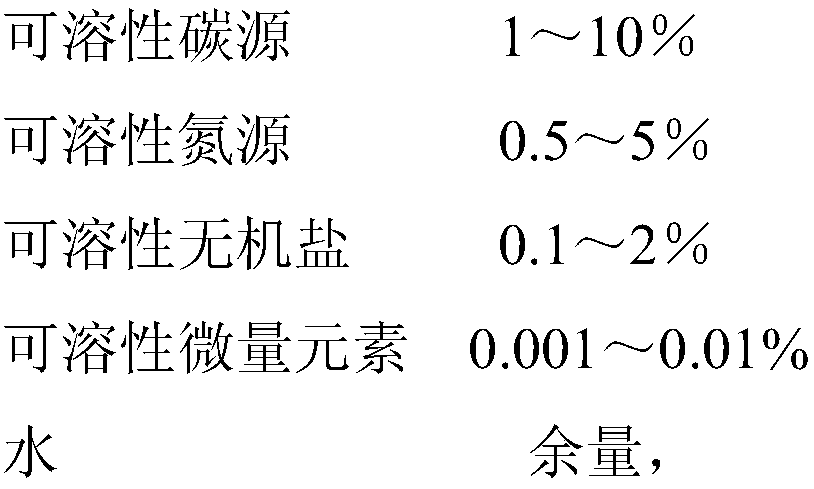

Method used

Image

Examples

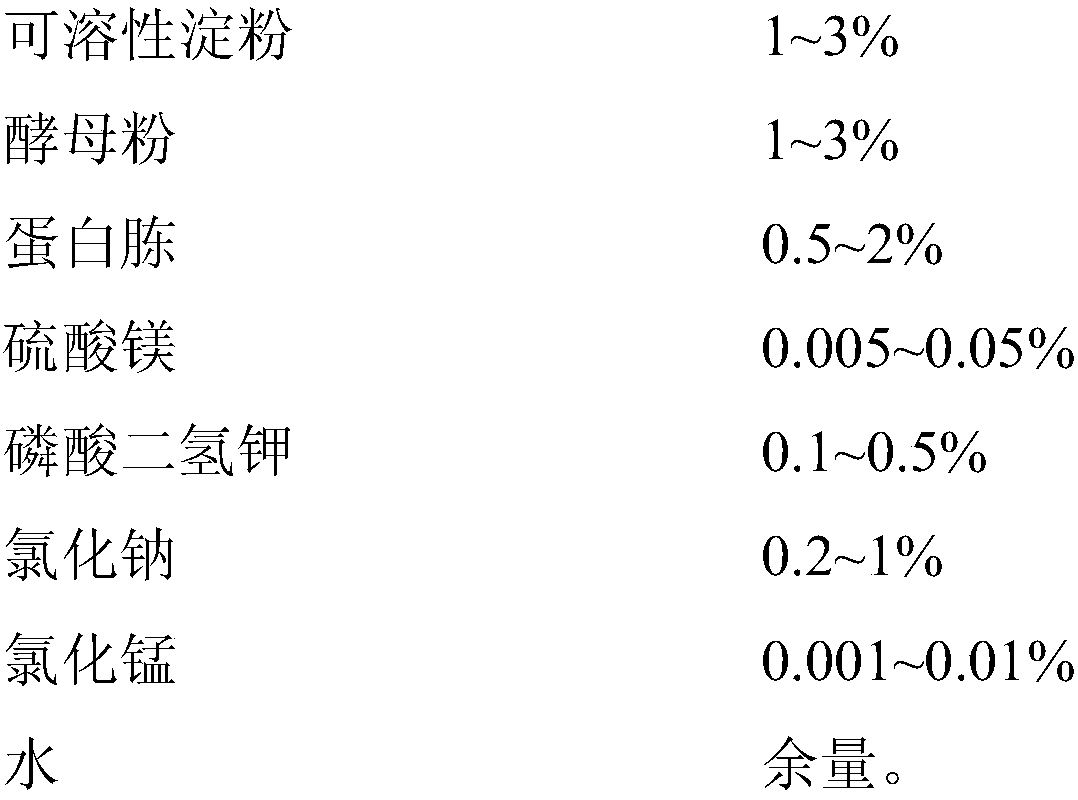

Embodiment 1

[0033] The first step: preparation of bacteria powder

[0034] 1. The liquid fermentation medium is prepared according to the following formula: glucose 4%, yeast powder 2%, soluble starch 2%, peptone 0.5%, magnesium sulfate 0.01%, manganese chloride 0.005%, potassium dihydrogen phosphate 0.15%, chloride Sodium 0.5%, water added to 100%. The above ingredients are all water-soluble ingredients, which are easy to remove by centrifugation and washing after fermentation. At the same time, because they do not have softness and plasticity, even if there are residues in the bacterial powder, they will not affect the particle size of the grinding.

[0035] 2. After the medium is prepared and dissolved, adjust the pH to 7.2, sterilize with high-pressure steam at 120°C for 30 minutes, pass in sterile air with a ventilation rate of 1.5v / v / min, cool to 31°C, insert bacteria to maintain temperature and The ventilation rate remains unchanged to start fermentation. Fermentation is complete...

Embodiment 2

[0039] The first step: preparation of bacterial powder

[0040] 1. The liquid fermentation medium is prepared according to the following formula: 5% glucose, 1% yeast powder, 1% soluble starch, 2% peptone, 0.05% magnesium sulfate, 0.001% manganese chloride, 0.3% potassium dihydrogen phosphate, Sodium 0.3%, water added to 100%.

[0041] 2. After the medium is prepared and dissolved, adjust the pH to 7.0, sterilize with high-pressure steam at 120°C for 30 minutes, introduce sterile air, ventilation rate 1v / v / min, cool to 33°C, insert bacteria to maintain temperature and ventilation The amount remains unchanged to start fermentation. Fermentation was completed after 20 hours, acidified pH was 4 after feeding, centrifuged and concentrated to obtain a bacterial slurry with a solid content of 15%, washed with water to remove the residual medium, and finally the bacterial slurry was concentrated and spray-dried to obtain bacterial powder.

[0042] The second step: preparation of oi...

Embodiment 3

[0045] The first step: preparation of bacteria powder

[0046] 1. The liquid fermentation medium is prepared according to the following formula: glucose 2%, yeast powder 3%, soluble starch 3%, peptone 0.5%, magnesium sulfate 0.005%, manganese chloride 0.01%, potassium dihydrogen phosphate 0.4%, chloride Sodium 0.8%, water added to 100%.

[0047] 2. After the medium is prepared and dissolved, adjust the pH to 7.5, sterilize with high-pressure steam at 120°C for 30 minutes, pass in sterile air, ventilation rate 2v / v / min, cool to 30°C, insert bacteria to maintain temperature and ventilation The amount remains unchanged to start fermentation. Fermentation was completed after 40 hours, acidified pH was 5 after feeding, centrifuged and concentrated to obtain a bacterium slurry with a solid content of 8%, the bacterium slurry was washed with water to remove residual medium, and finally the bacterium slurry was concentrated and spray-dried to obtain bacterial powder.

[0048] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com