Multi-membrane reservoir sealing test

A leak detection and cabin technology, applied in container discharge methods, fluid tightness testing, container filling methods, etc., can solve problems such as difficult to find optical camera thermometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

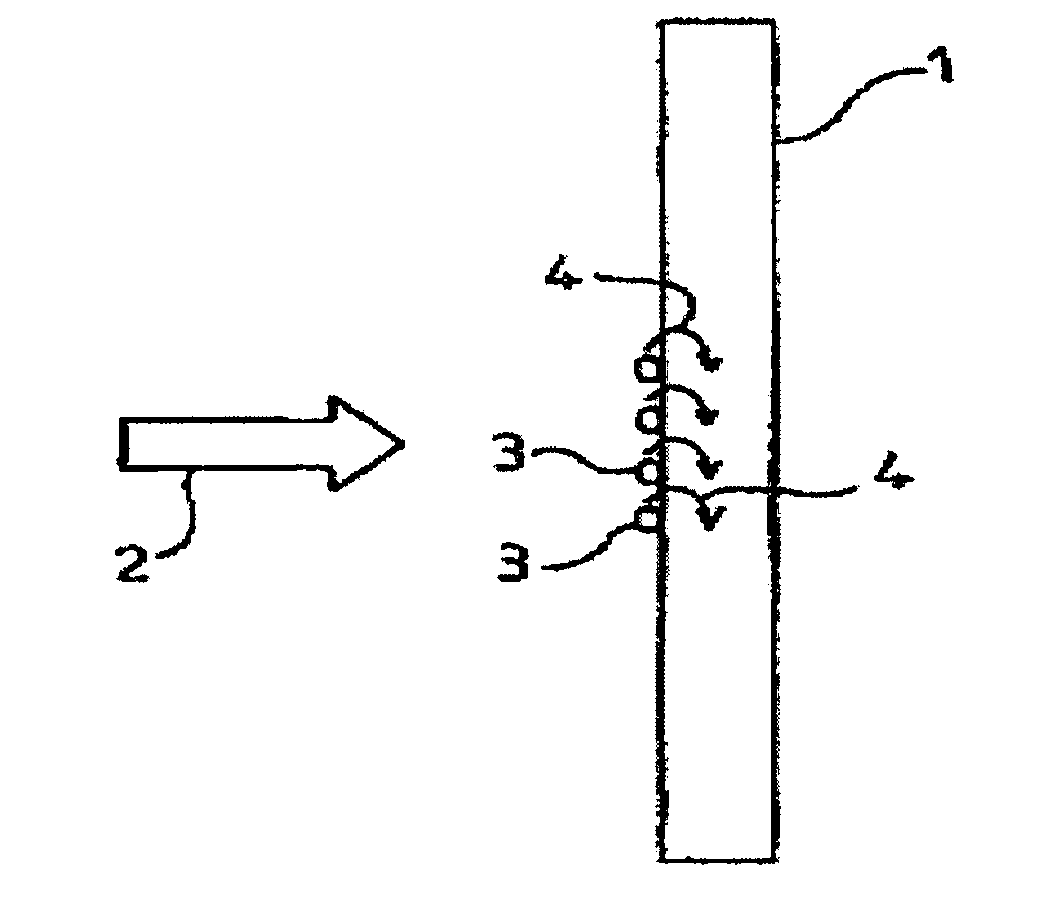

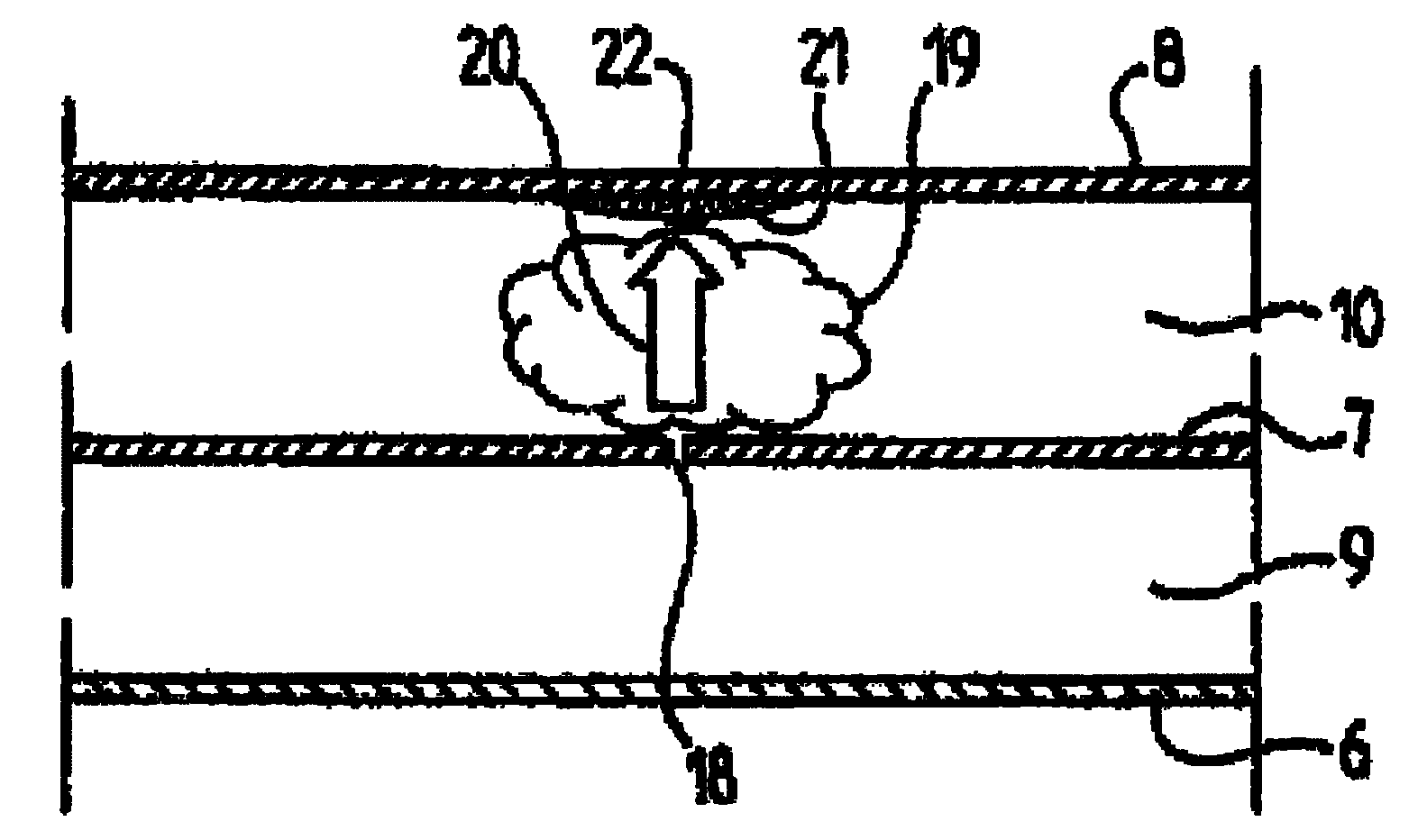

[0039] figure 1 Bulkhead 1 is depicted and the mean temperature of the bulkhead is TM. At pressure P the gas comes into contact with the bulkhead 1 as indicated by arrow 2 . If the condensation temperature TC of the gas is higher than the temperature TM, the gas will condense in the form of liquid or solid precipitate 3 . According to this mode, the gas condenses and releases latent heat which is transferred to the bulkhead 1 . This thermal energy transfer is indicated by arrow 4, therefore, the local temperature T of the bulkhead 1 will be higher than TM. When the temperature TM, pressure P and the nature of the gas are controllable, the condensation at this time is called forced condensation.

[0040] Such gases may be:

[0041] A single gas whose inherent physical properties correspond to the ideal condensation temperature.

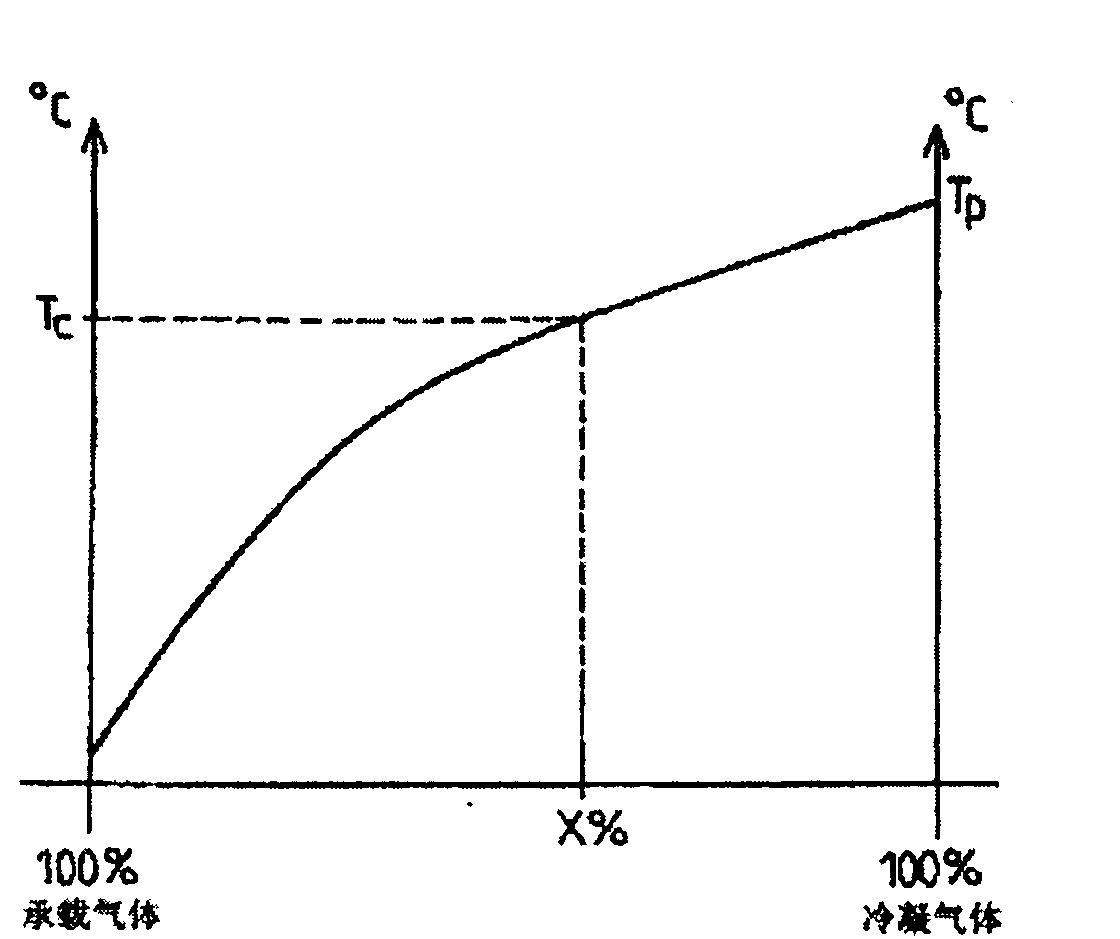

[0042] A mixture of noncondensable and condensable gases whose concentration can be adjusted to suit the condensation temperature. Specifically,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com