Shredder

A paper shredder and paper guide mechanism technology, which is applied to grain processing and other directions, can solve the problems of large paper particles, low paper shredding efficiency, and failure to meet the destruction standards of primary shredders, and achieves comprehensive paper shredding and uniform particles , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

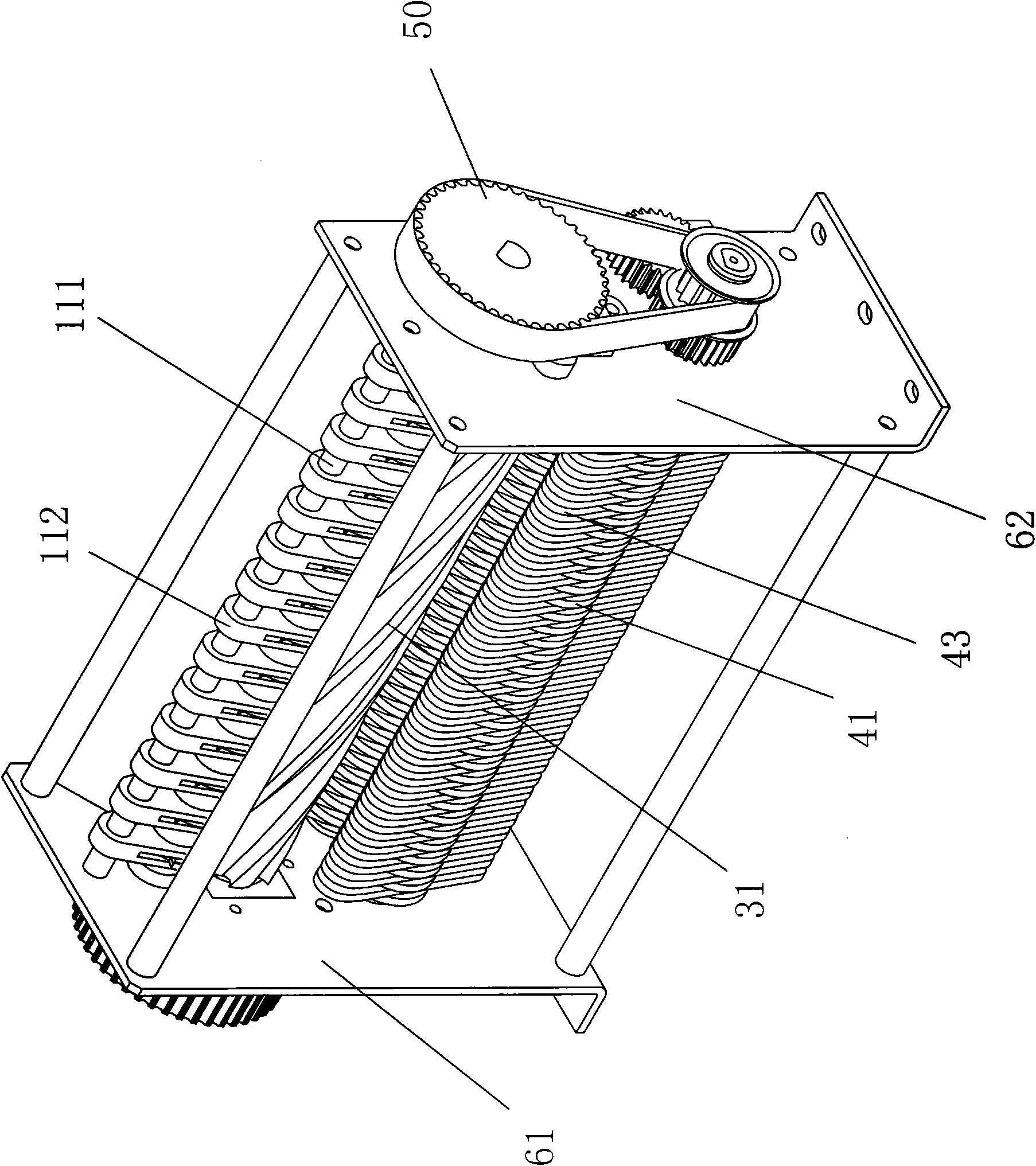

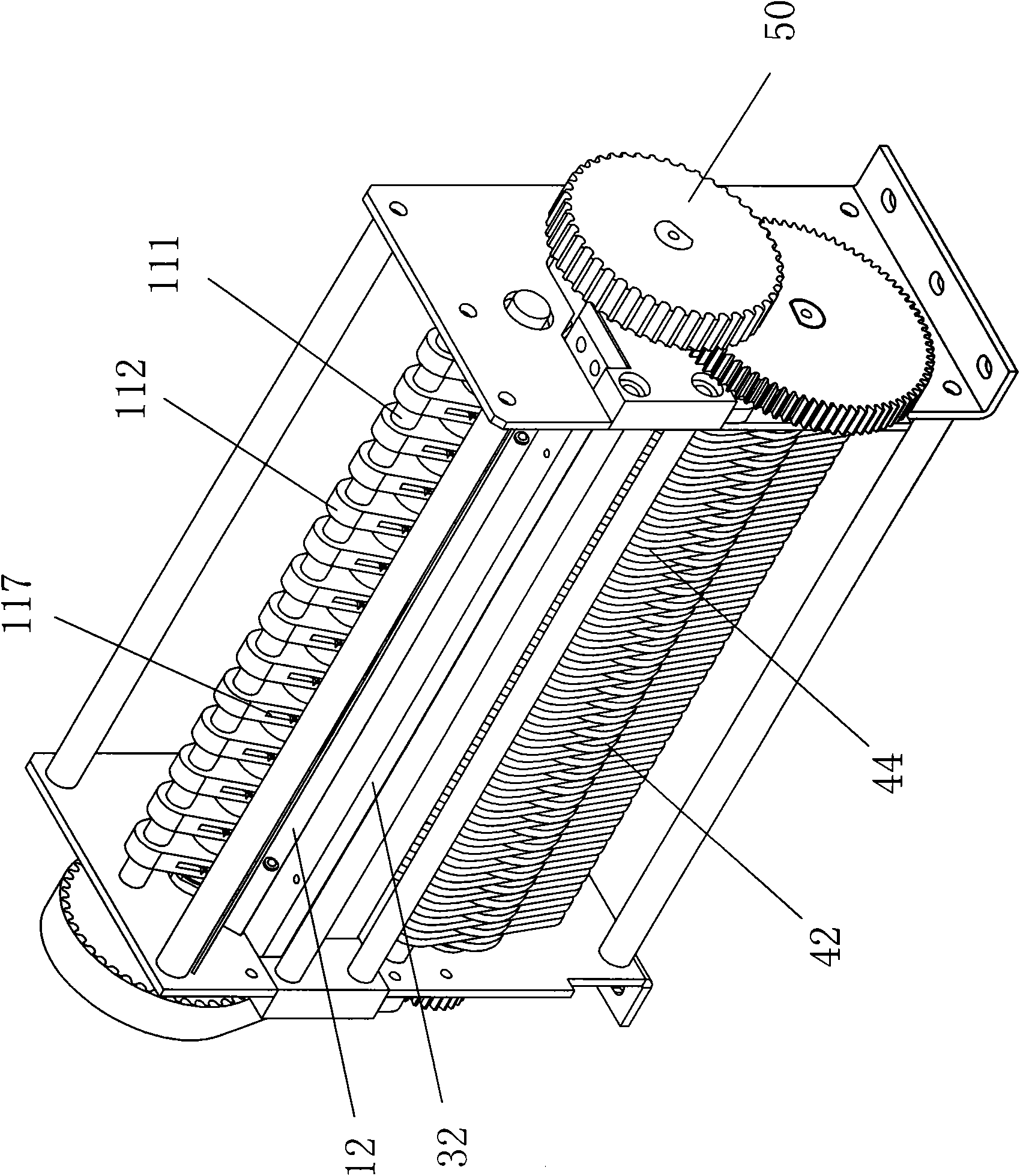

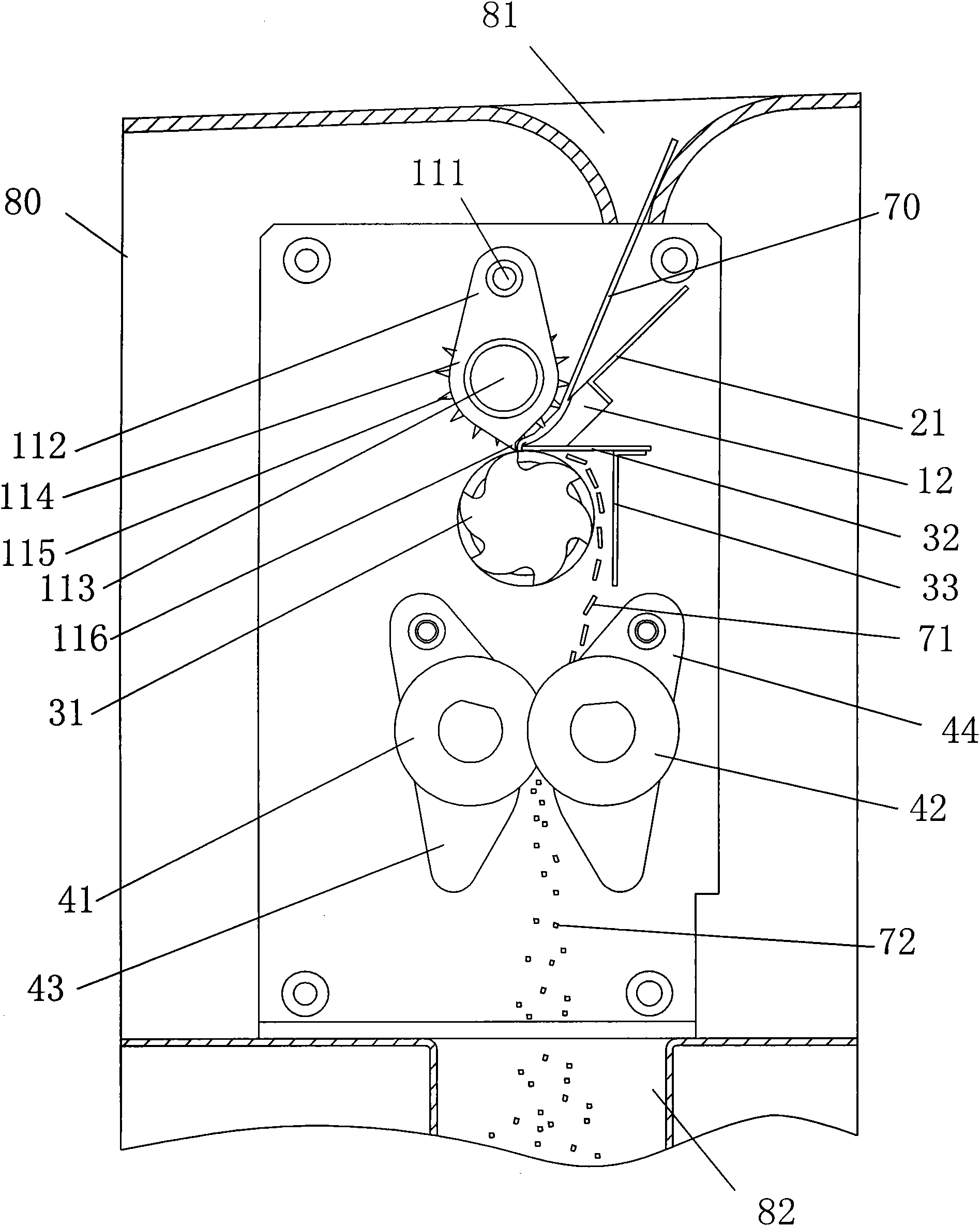

[0018] Such as Figure 1 to Figure 6 As shown, the paper shredder of the present invention includes a casing 80, the top and bottom of the casing 80 are respectively provided with a paper inlet 81 and a paper outlet 82, and a paper guide mechanism for rolling in and conveying the paper 70 is installed in the casing 80 , a horizontal paper cutting mechanism for cutting the paper 70 into horizontal strips 71 and a vertical paper cutting mechanism for cutting the horizontal strips 71 into particles 72, the horizontal paper cutting mechanism is located below the paper guide mechanism, the The vertical paper cutting mechanism is located below the horizontal paper cutting mechanism. The paper guide mechanism, the horizontal paper cutting mechanism and the vertical paper cutting mechanism are all connected to the transmission mechanism 50. The paper inlet 81 is set correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com