Adaptability position correction device

A compliant and component-compliant technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve problems such as the inability of the robotic arm to complete correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

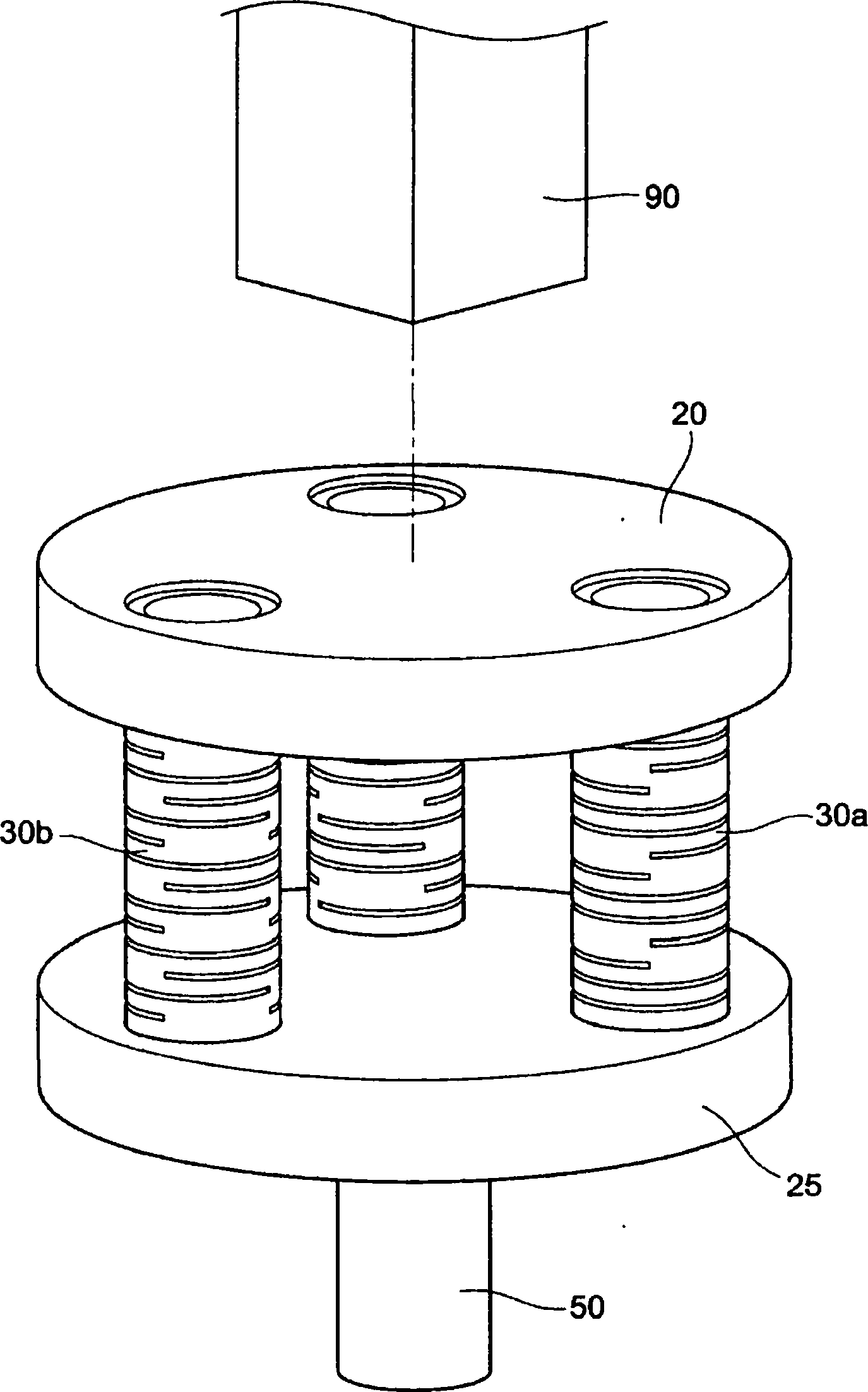

[0028] Please refer to figure 1 , which is a schematic perspective view of the first embodiment of the compliance position correction device according to the present invention. The compliance position correction device (or remote center compliance device, Remote center compliance device) is suitable for connecting to the remote 90 (Remote End) of a robot arm, and corrects the errors caused by the error of the robot arm, rigidity factors, Or the offset caused by positioning error. This offset may occur on a single axis (such as one of the two horizontal axes or the vertical axis), or it may occur on all three axes (two horizontal axes and the vertical axis) at the same time. Through the compliance position correction device, the offset of the aforementioned single axis or three axes can be corrected.

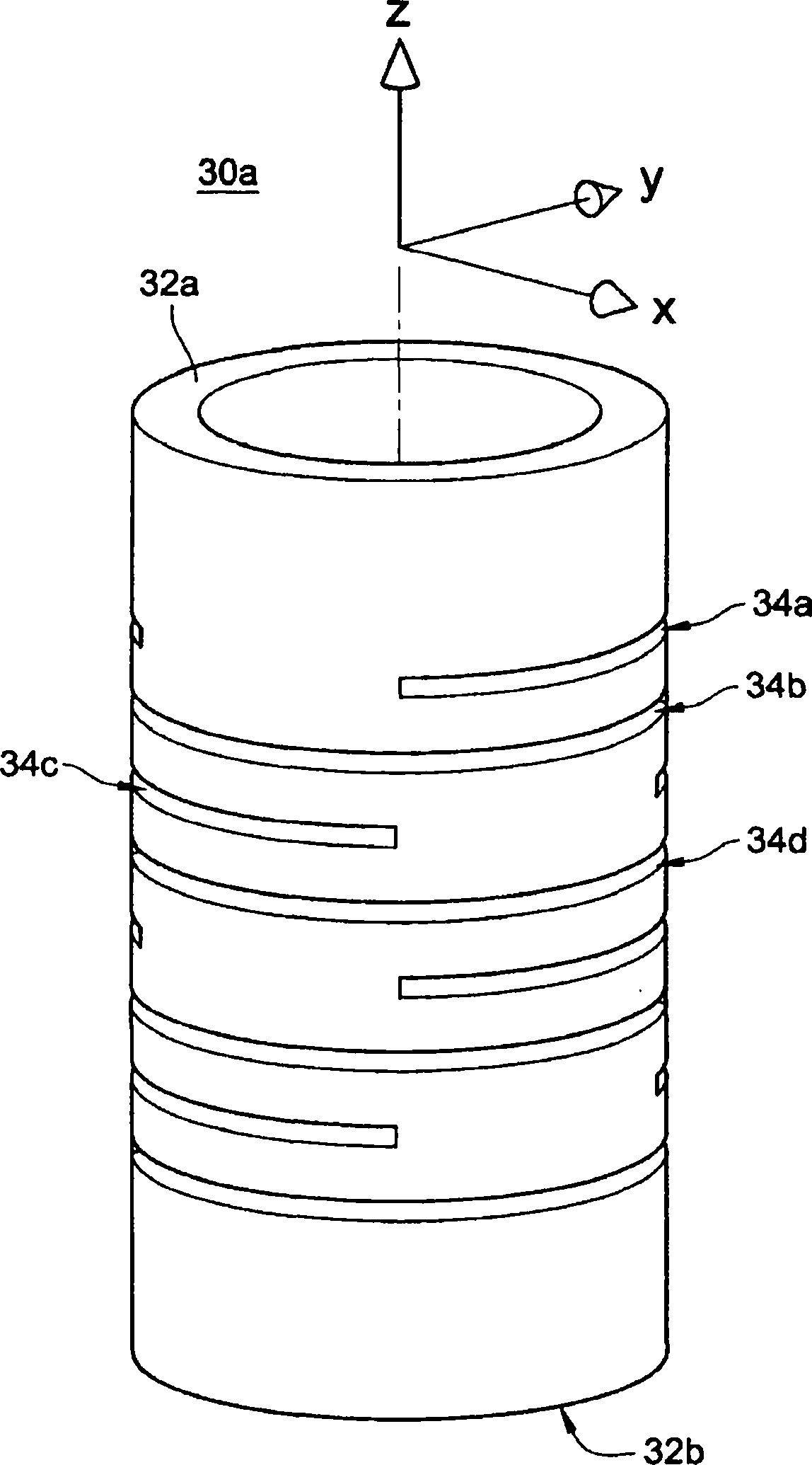

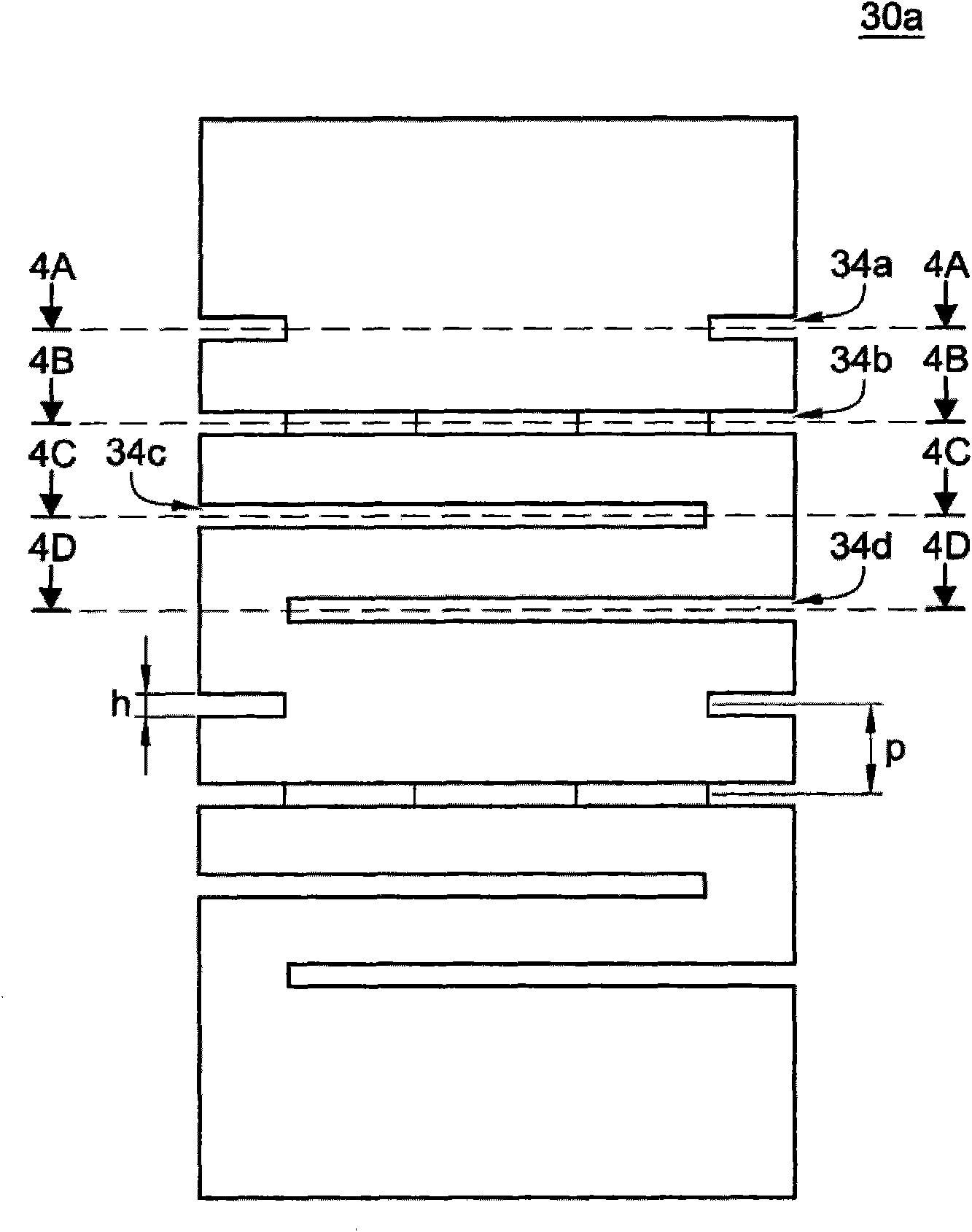

[0029] Please also see figure 1 and figure 2 , figure 2 It is a three-dimensional schematic diagram of the first embodiment of the position compliance component of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com