Deep hole machining device and method

A processing device and deep hole technology, used in metal processing equipment, manufacturing tools, boring/drilling and other directions, can solve the problems of troublesome process, complex process, high equipment requirements, reduce the cumulative error of transmission, reduce the complexity, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

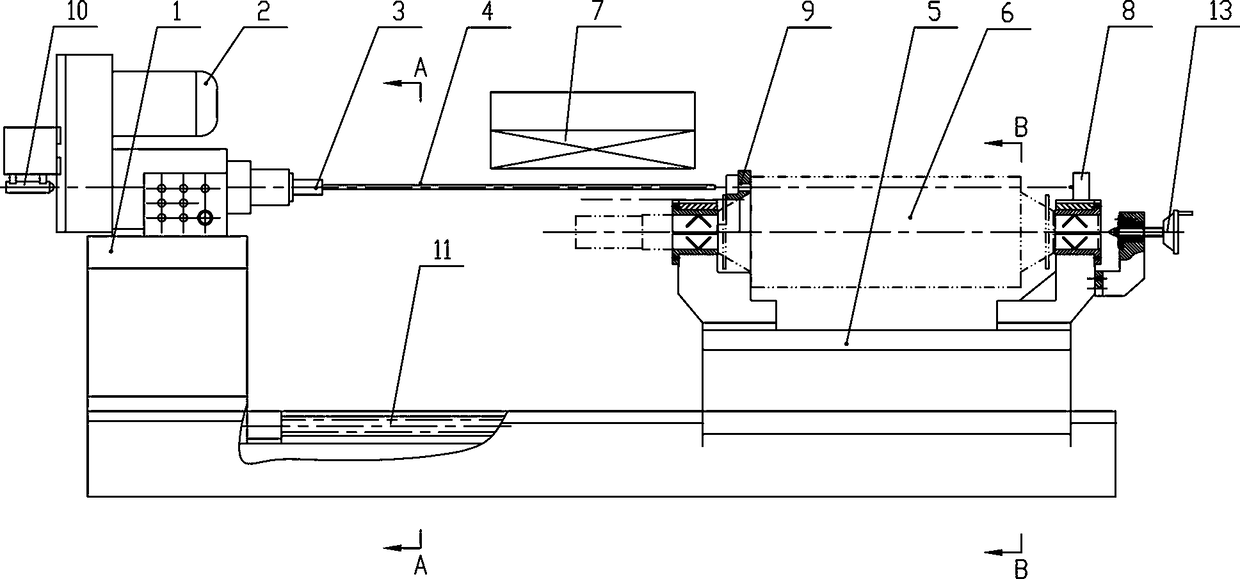

[0031] Such as Figure 1~3 Among them, a deep hole processing device includes a bed 1, a drilling power head 2 is fixed on the bed 1, and a deep hole drill 4 is installed on the drilling power head 2. In the drilling power head 2, The drill base is connected with the motor through the transmission mechanism. The deep hole drill bit 4 is fixedly installed on the drill base. The workbench 5 is slidably installed on the bed 1 through the guide rail. They are also connected by a lead screw nut mechanism 11, the workpiece 6 is clamped on the workbench 5, and the feed of the workpiece is realized by the lead screw nut mechanism 11. By adopting the feeding method of the worktable 5, the transmission mechanism is reduced in the drilling power head 2, that is, the cumulative error caused by the transmission mechanism is reduced.

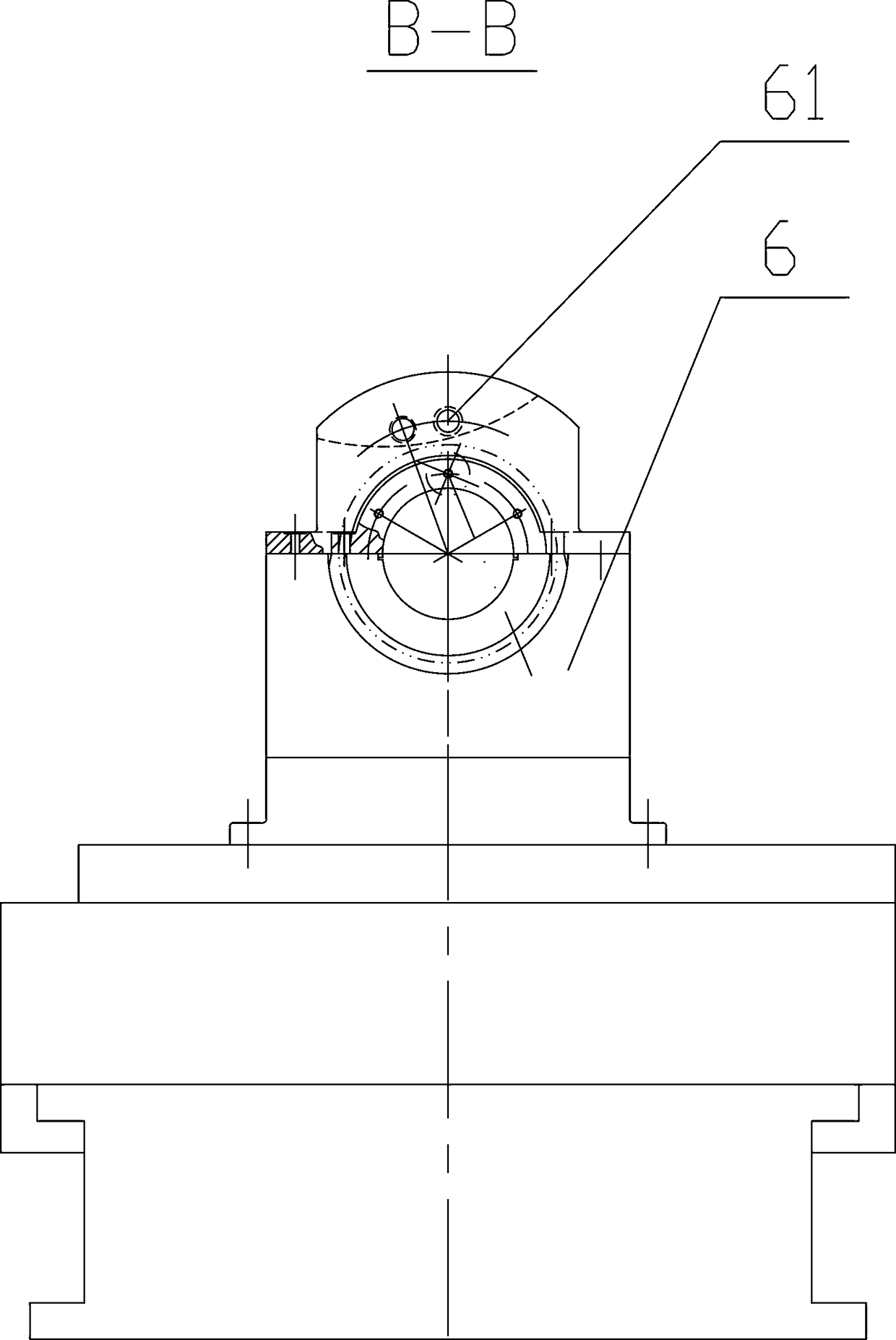

[0032] In a preferred solution, the workpiece 6 is rotatably clamped on the fixture 9 of the workbench 5 through a shaft, and the fixture 9 is also provided...

Embodiment 2

[0039] On the basis of Example 1, the preferred scheme is as figure 1 , 5 Among them, a laser-assisted calibration device is also provided. The structure is: a laser emitting device 10 is provided at one end of the bed, and a photoelectric collector 8 is provided at the other end. The laser emitting device 10 is used to emit a beam of collimated laser light through the deep hole. The drill bit 4 and the workpiece 6 are received by the photoelectric collector 8 .

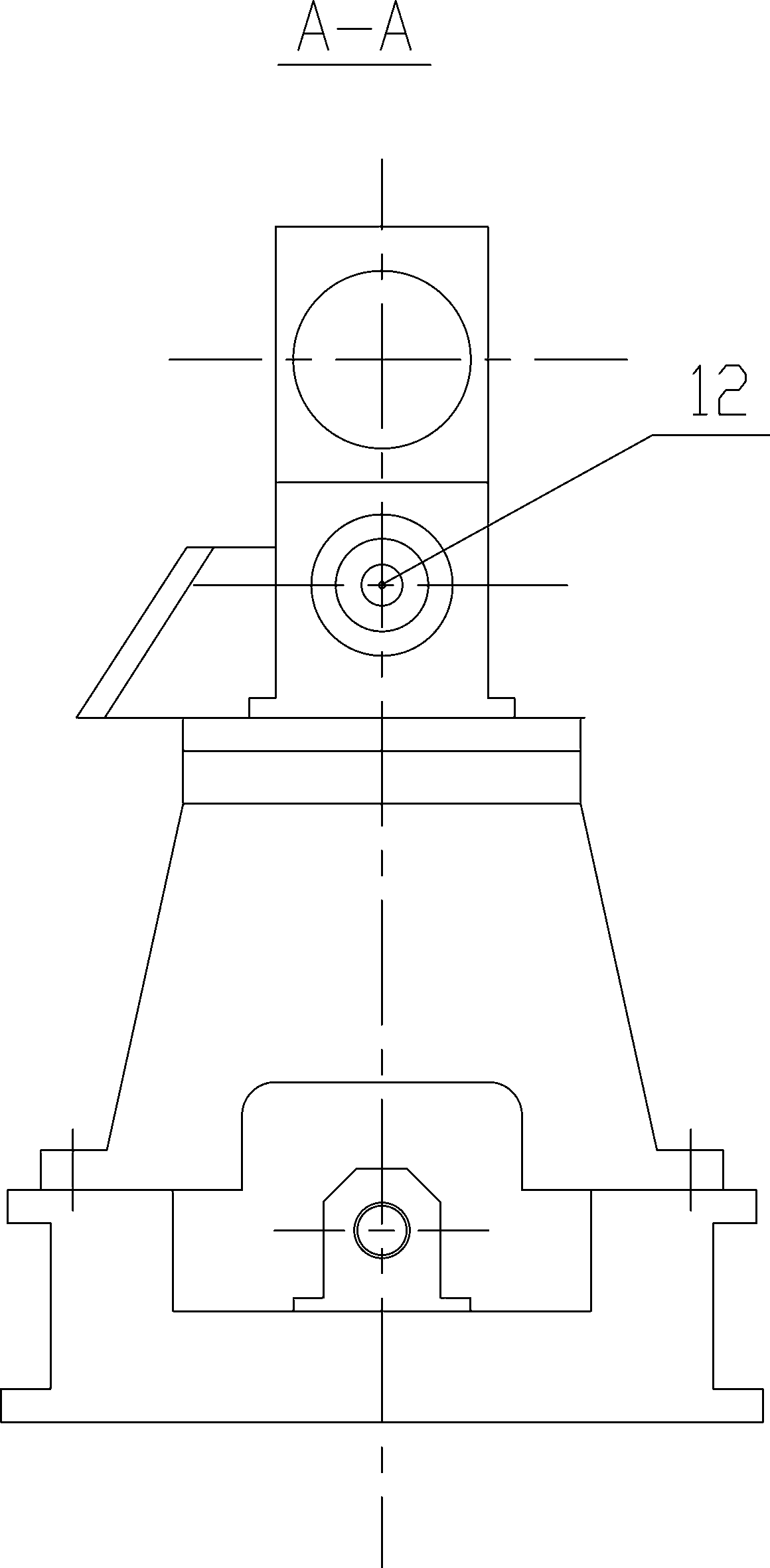

[0040] In a preferred solution, the laser emitting device 10 is fixed on the drilling power head 2, and the laser emitting device 10 is used to emit a beam of laser beams along the axis of the deep hole drill 4, between the drilling power head 2 and the deep hole drill 4 There is a correction hole 12 on it;

[0041] The photoelectric collector 8 is fixed on the side of the fixture 9 away from the deep hole drill 4 , and an array of photosensitive elements is arranged on the photoelectric collector 8 . Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com