Container case for vertically transporting gas bottles

A vertical, containerized technology, applied in the direction of transportation and packaging, packaging, containers, etc., can solve the problems of potential safety hazards, low work efficiency, inconvenient loading and unloading, and movement, and achieve convenient vehicle transportation, high work efficiency, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

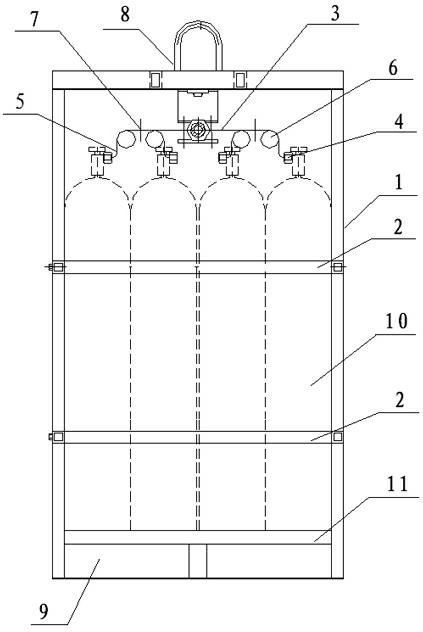

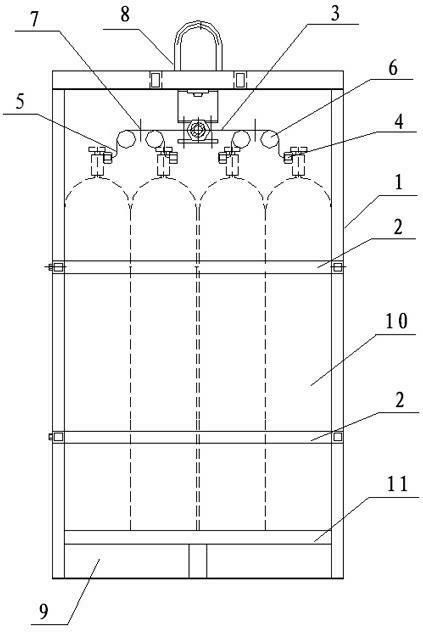

[0012] Such as figure 1 As shown, a vertical transport container for gas cylinders, a vertical transport container, is mainly a frame body 1, a stop bar 2 is provided in the middle of the frame body 1, and a bottom plate 11 is provided at the bottom, and the gas cylinder 10 is placed On the bottom plate 11 and limited by a stopper bar, the feature is that a bus bar 3 is installed on the top of the frame body 1 , and the bus bar includes a joint 4 , a pipe 5 , a pressure gauge 6 and a stop valve 7 .

Embodiment 2

[0014] It is different from the vertical transport container for gas cylinders in Embodiment 1, except that a lifting ring 8 is installed on the top of the frame to facilitate hoisting and transfer by a crane.

Embodiment 3

[0016] It is the same as the gas cylinder upright transportation container in Embodiment 1, the difference is that a fork opening 9 is provided under the bottom plate 11, which is convenient for forklift handling 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com