Gear support and method of manufacturing the same

A manufacturing method and technology for gear racks, which are applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of increasing the number of processing steps and decreasing the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

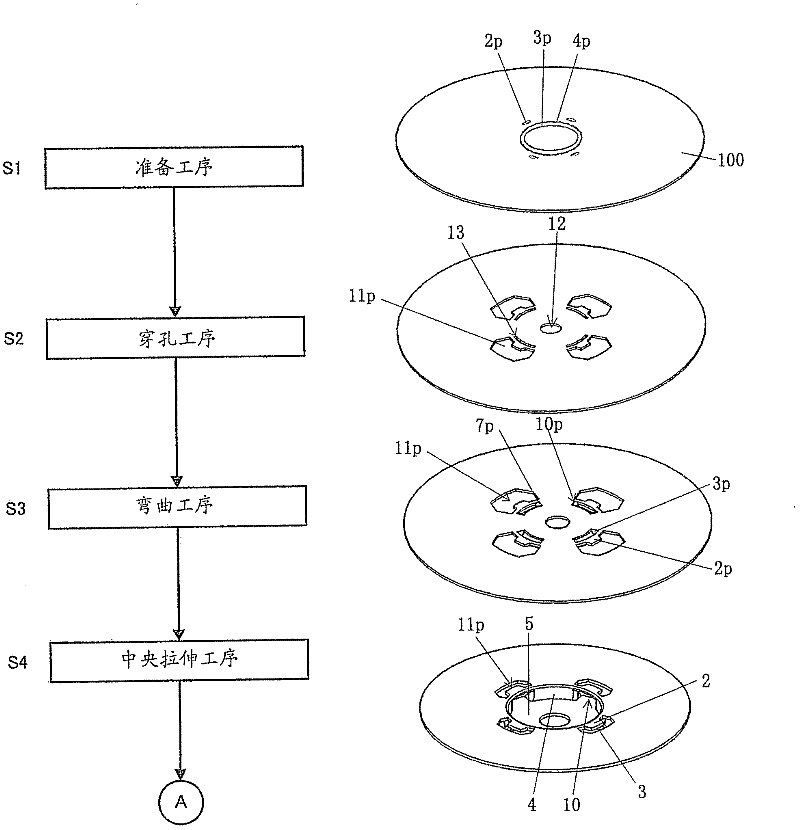

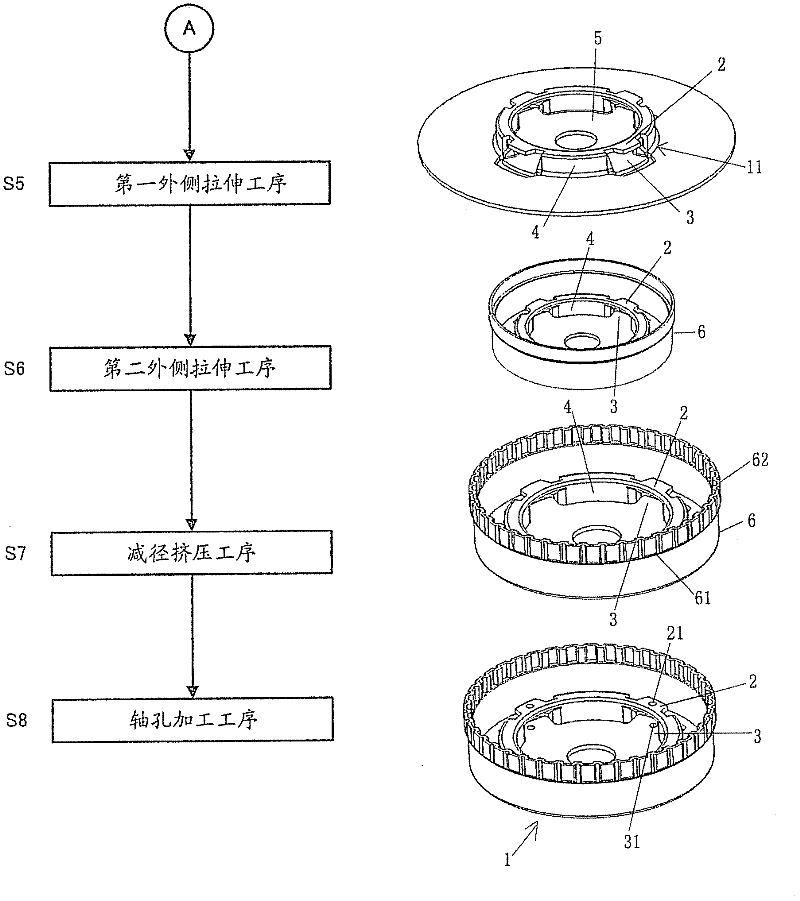

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the positional relationship of each component is described based on the up-down relationship in the figure. However, the up-down relationship in the following description is for the convenience of explanation after all, and is not intended to be used during molding or use. It is required to configure each component according to its upper and lower relationship. In addition, parts in the middle of forming are collectively referred to as workpieces.

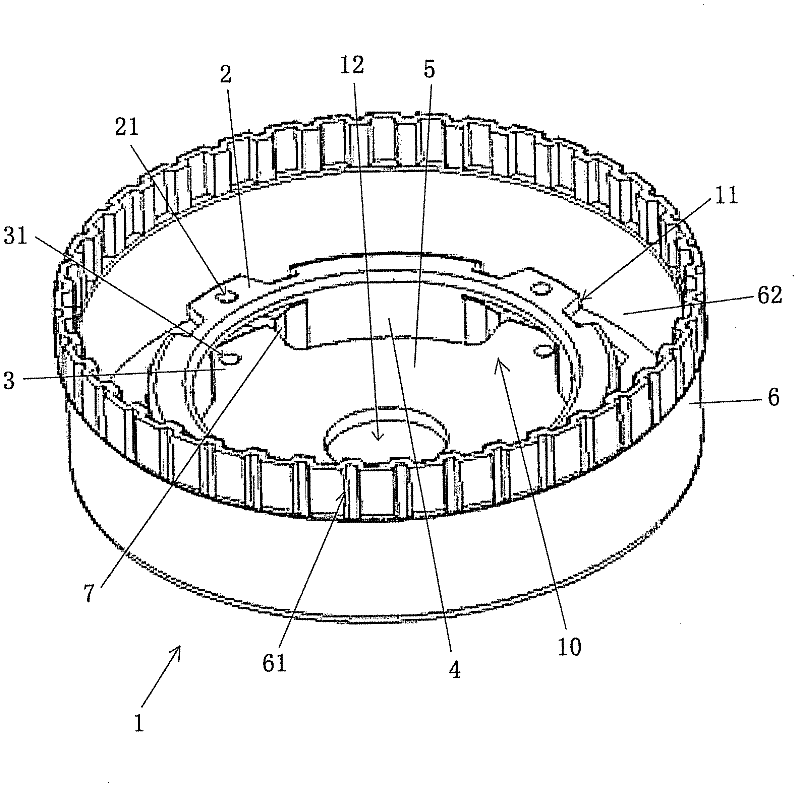

[0035] figure 1 It is a perspective view of the carrier 1 manufactured by the manufacturing method of embodiment of this invention.

[0036] The carrier 1 has a parallel upper support surface 2 and a lower support surface 3 for supporting a planetary gear not shown in the figure, and is arranged between the positions where the upper support surface 2 and the lower support surface 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com