Patents

Literature

97results about How to "No loss of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

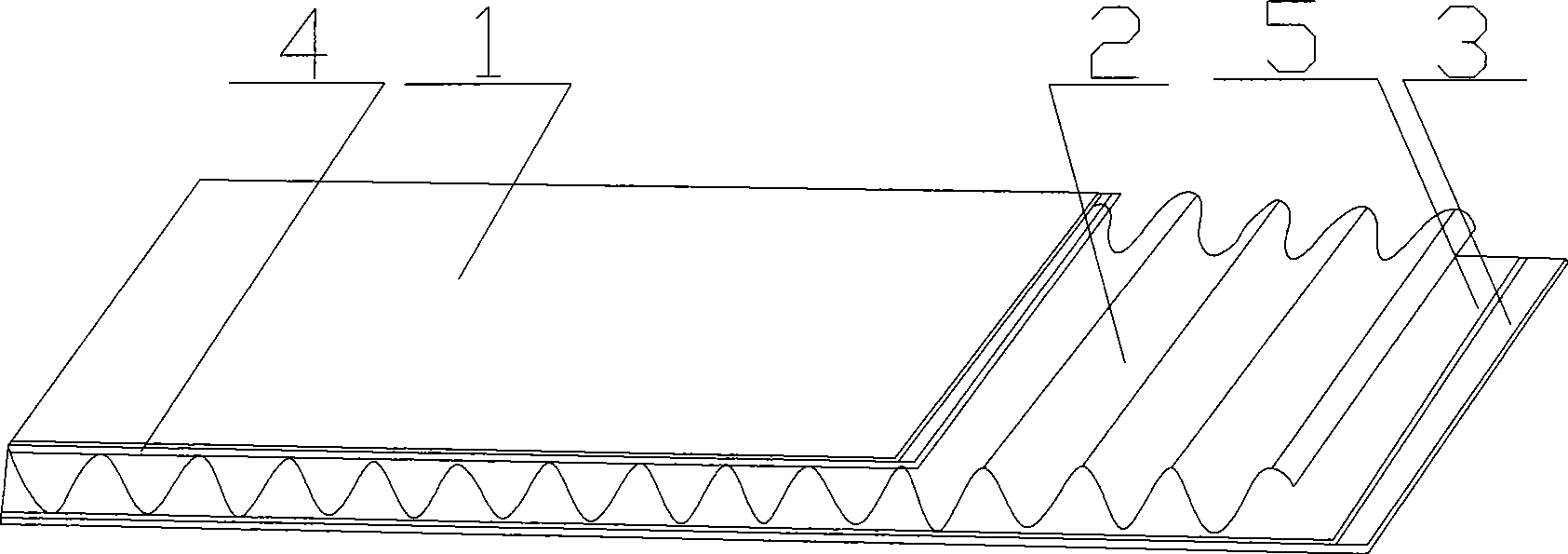

Composite material construction for high-speed train and its manufacturing method

InactiveCN101289017ARealize continuous variable thickness designImprove continuityLamination ancillary operationsLaminationGlass fiberEpoxy

The invention discloses a compound material used for a high-speed train and a manufacturing method thereof. A strengthening aluminum alloy layer panel with an upper layer of fiberglass and a lower layer of fiberglass is adopted to replace the existing single aluminum alloy panel, and the form of vicarious joint on the inside of the fiberglass strengthening aluminum alloy layer panel by an aluminum alloy thin plate and a high-strengthening fiberglass enhanced epoxide resin layer plate to realize the continuity of the large panels. The compound material of the invention has the excellent qualities of light quantity, high intensity, high anti-fatigue property, high impact damage allowance and high burning resistance property, etc.

Owner:TONGJI UNIV

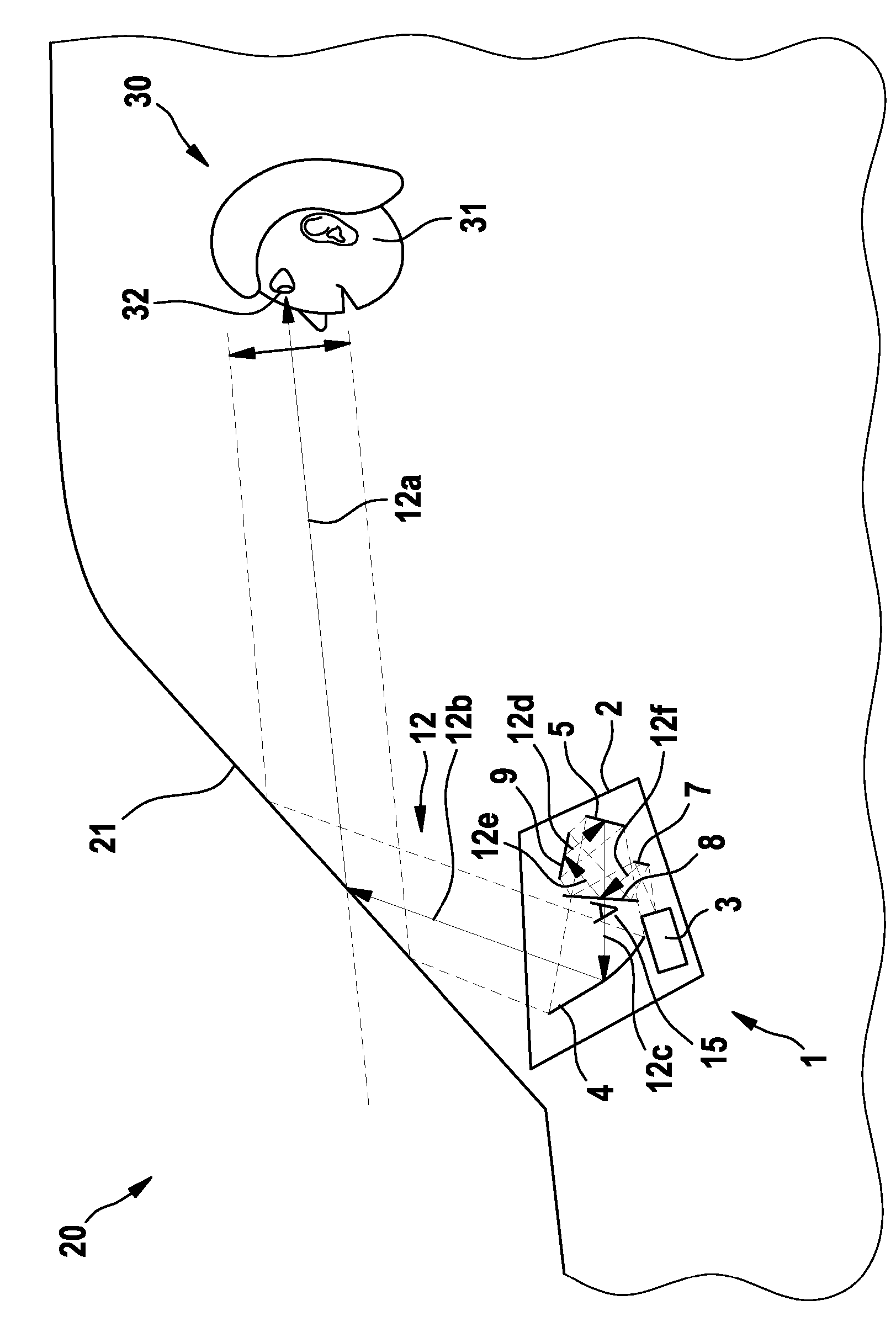

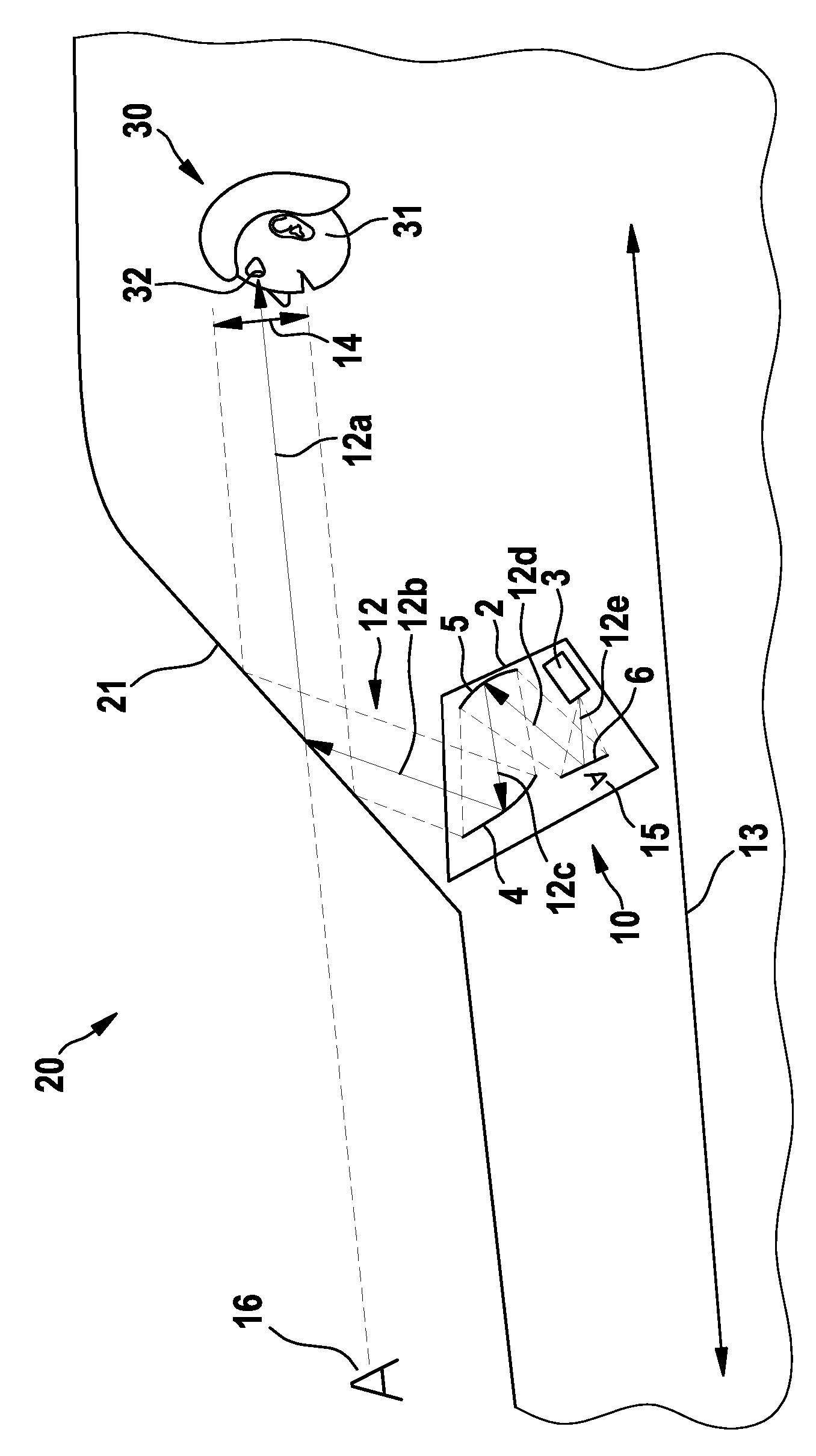

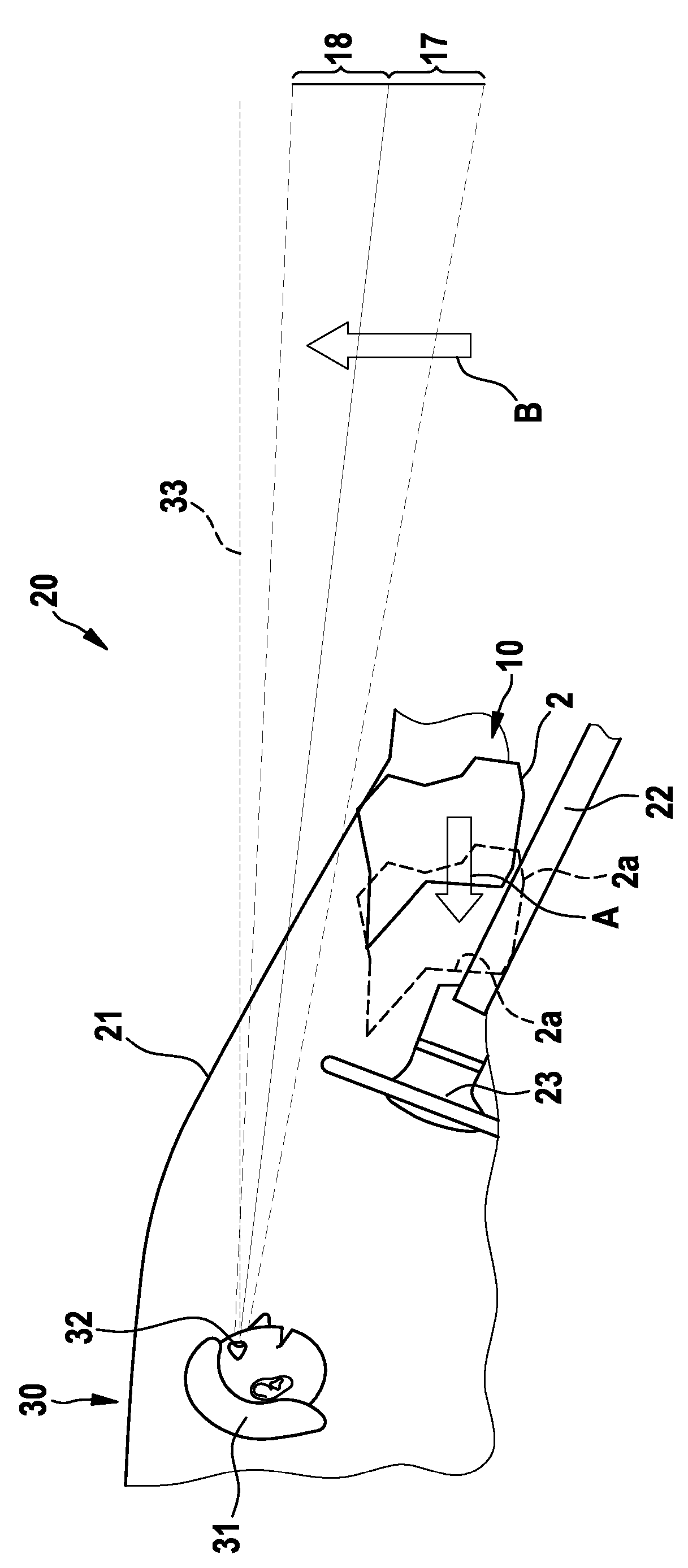

HUD comprising holographic optical elements

A display device (1), more particularly a head-up display, comprising a light-emitting image source (3) and comprising optical elements (4, 5, 6, 7, 8, 9) forming a beam path (12) for beams is presented. In this case, the optical elements (4, 5, 6, 7, 8, 9) comprise a holographic optical element (8) having a predefined optical imaging function and a reflector (5). The holographic optical element (8) is positioned in a manner spatially separated from the reflector (5) in the beam path (12). Moreover, the holographic optical element (8) is arranged in the beam path (12) in such a way that beams in a first section of the beam path are directed onto the holographic optical element (8) in order to deflect them under the influence of the imaging function of the holographic optical element (8) into a second section of the beam path in a new direction. The reflector (5) and the holographic optical element (8) are arranged relative to one another in such a way that beams emitted by the reflector (5) into a third section of the beam path (12) can at least partly transilluminate the holographic optical element, wherein illumination angles of transilluminating beams in the third section of the beam path (12) substantially deviate from angles of incidence at which an influence of the imaging function of the holographic optical element (8) is effective.

Owner:ROBERT BOSCH GMBH

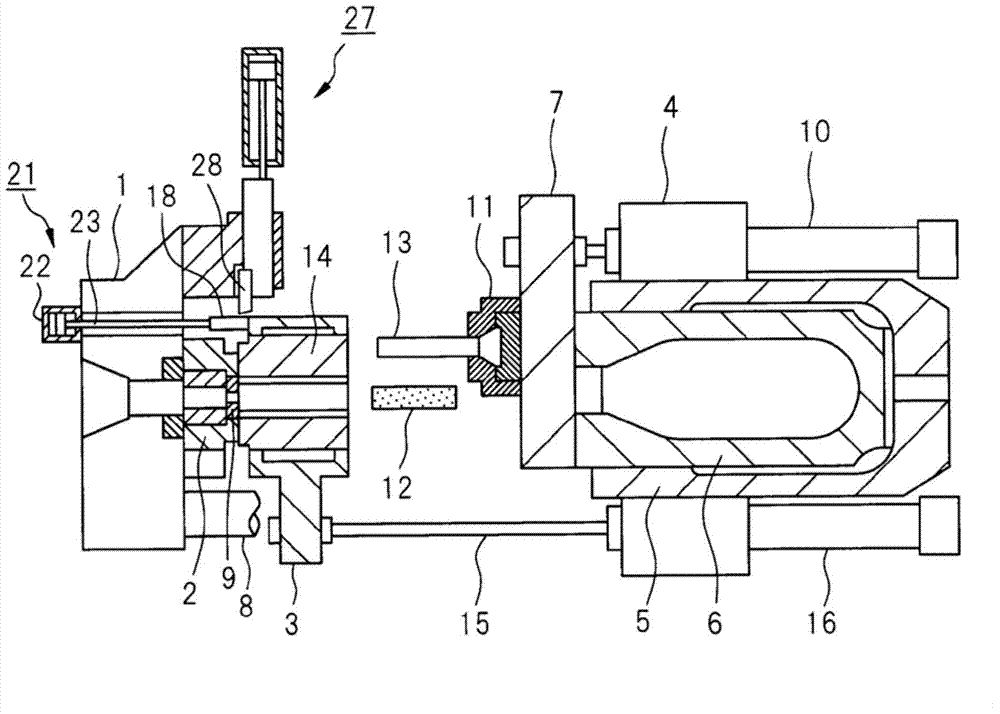

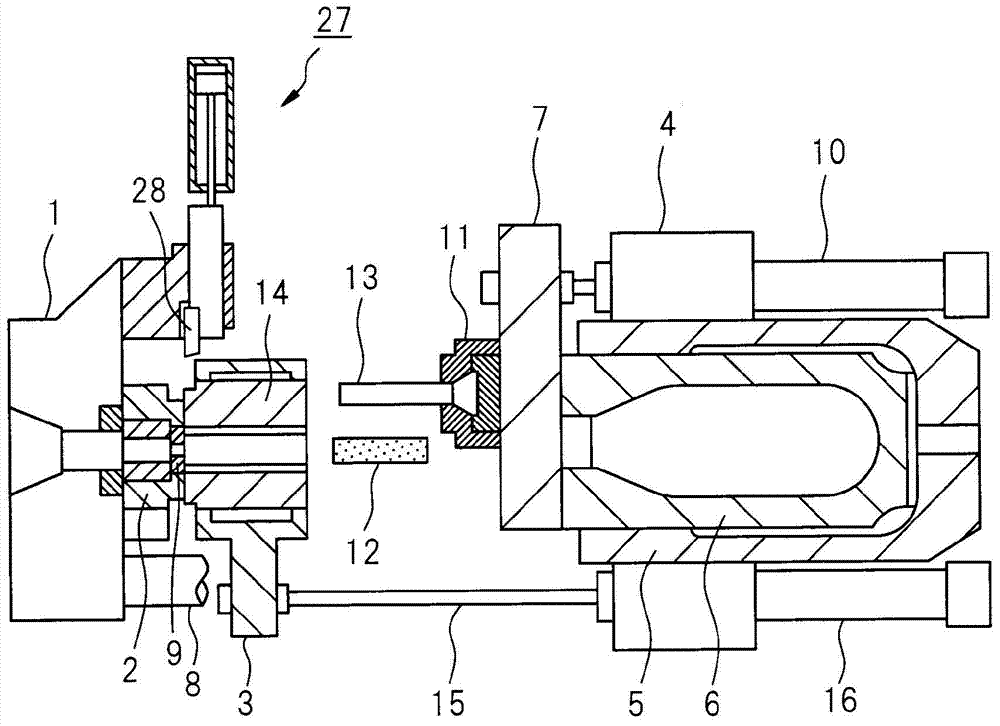

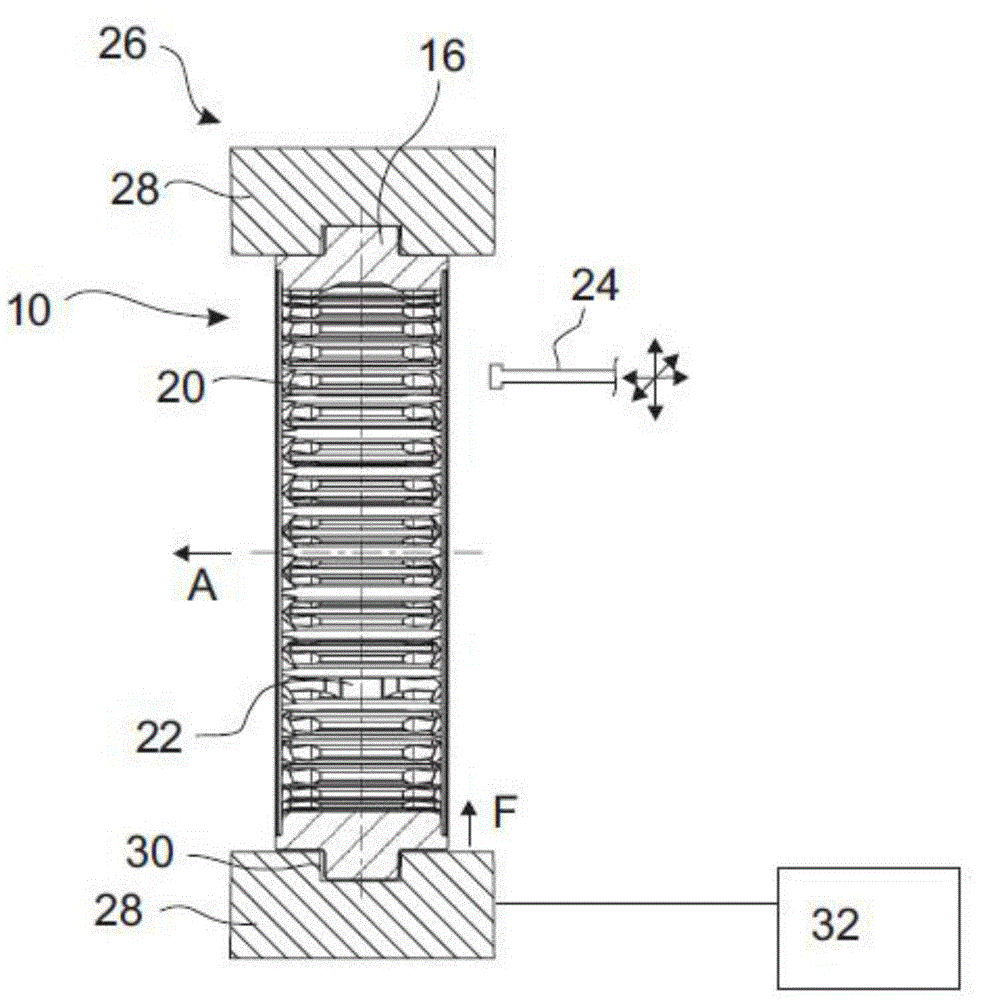

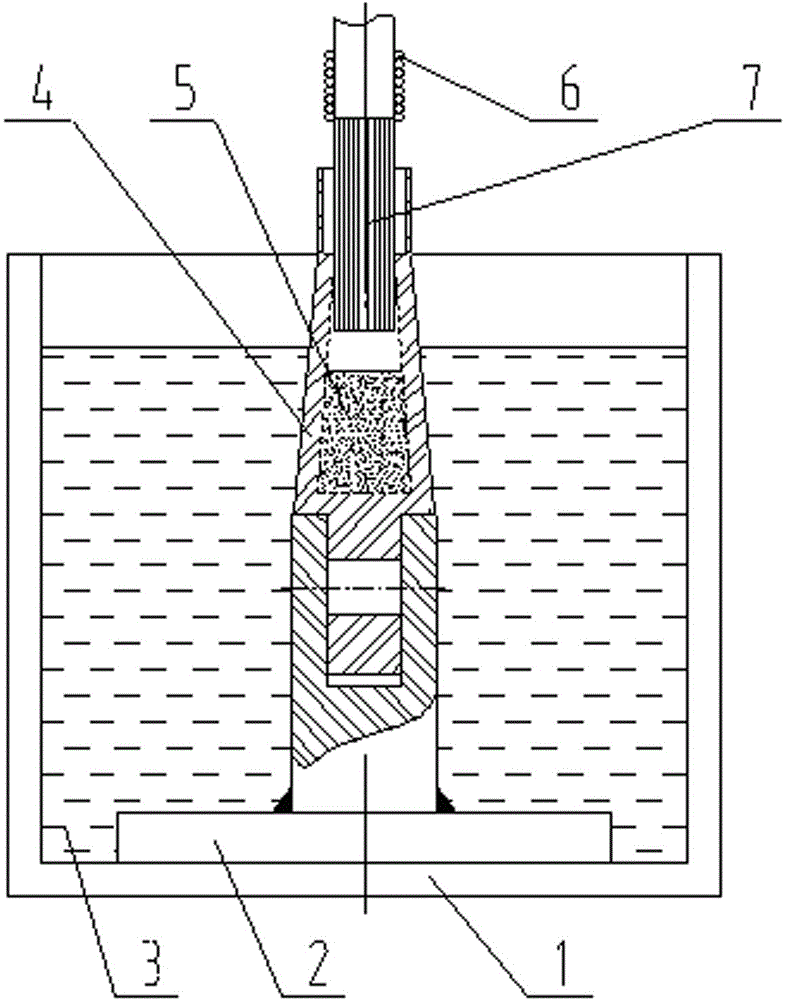

Extrusion press

ActiveCN103687679AIncreased peel forceNo loss of strengthExtrusion containersMechanical engineeringStroke Type

Provided is a short stroke type extrusion press which is capable of increasing a container strip force, improving energy efficiency, and saving space by reducing apparatus length. A main cylinder housing (4) of the extrusion press comprises a transfer medium (10) which advances or retreats an extrusion stem (13) in an extrusion axis direction, and a transfer medium (16) which advances or retreats a container (14) in the extrusion axis direction. A container pushing medium (21) is disposed at an end platen (1) disposed opposite the main cylinder housing (4) and makes it possible for at least four different transfer motions to be carried out independently or in collaboration with the container transfer medium in the direction in which the container (14) separates from a die (9).

Owner:UBE MASCH CORP LTD

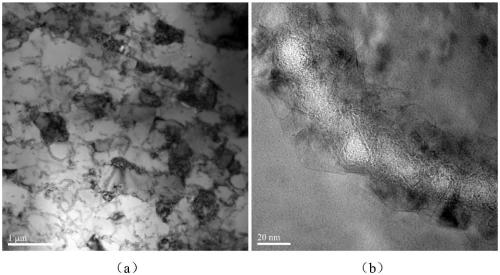

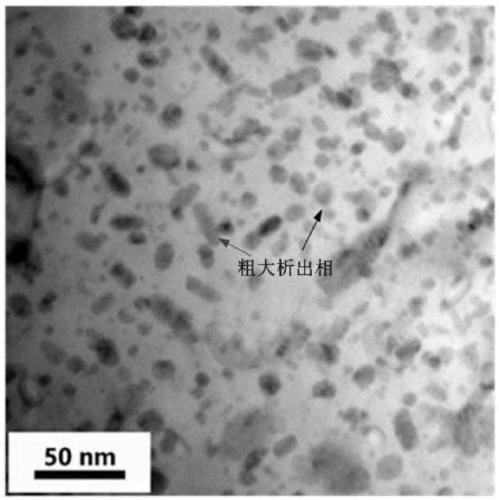

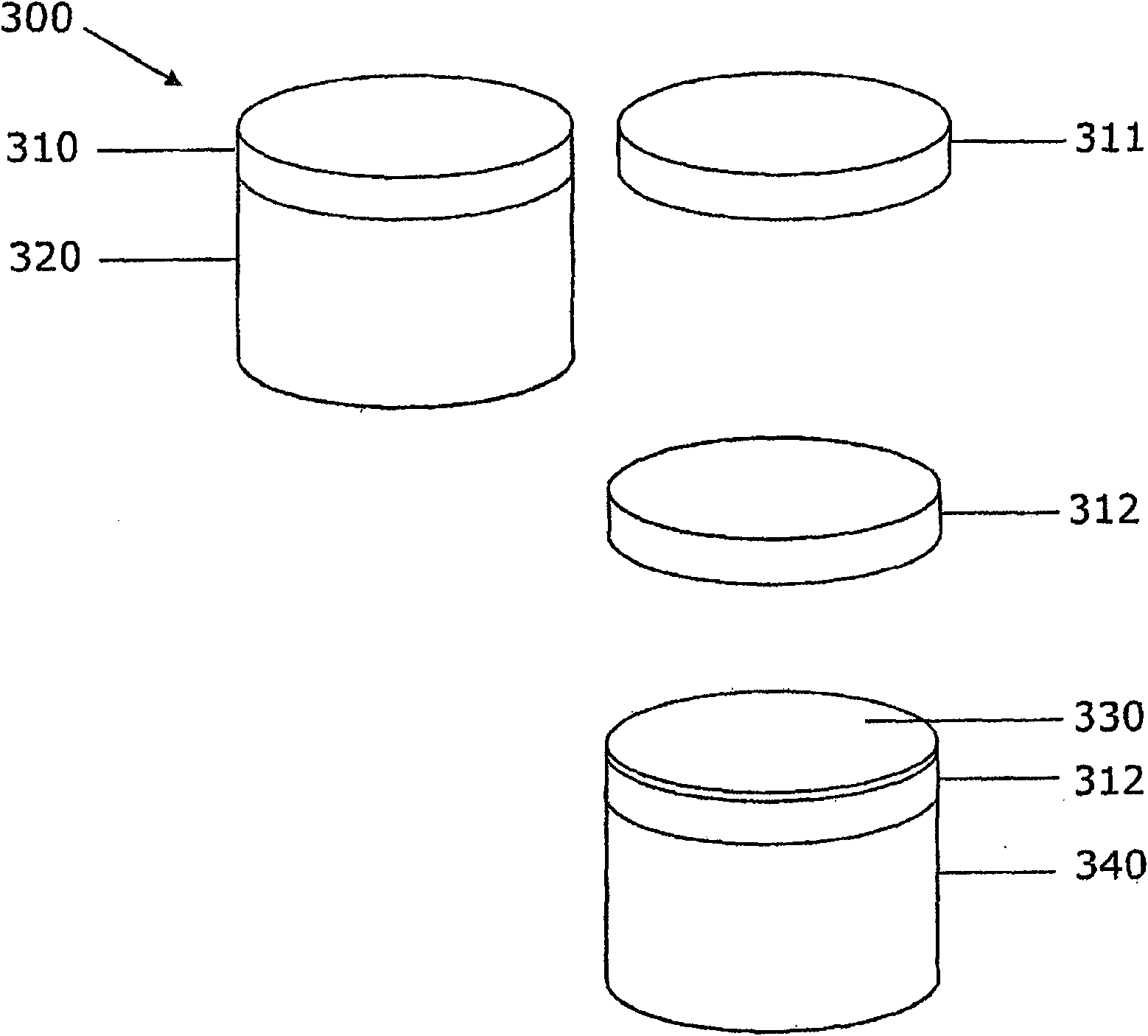

High-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material and method for preparing same

The invention discloses a high-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material and a method for preparing the same, and belongs to the technical field of metal-basecomposite materials. The method includes compressing superfine aluminum powder until the porosity of the superfine aluminum powder is appropriate, loading the superfine aluminum powder in jackets, sealing the jackets and drilling the peripheries of the jackets to allow an appropriate quantity air to flow into the jackets; placing the jackets in air furnaces, heating the jackets at the low temperatures and thickening oxidation films; increasing the temperatures until the temperatures reach the high temperatures, generating AlN and Al2O3 from nitrogen and oxygen in the air, sintering powder treated at the high temperatures, and carrying out heat processing on the powder to obtain the high-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material which is an (AlN+Al2O3) / Al composite material with excellent high-temperature strength and heat resistance. The high-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material and the method have the advantages that the air is used as oxygen and nitrogen sources, and complicated equipment can be omitted; risks such as aluminum powder combustion can be prevented, the quantities of oxide and nitride can be easily regulated and controlled, and the high-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material and the method are short in period, low in cost, easy to control and suitable for large-scale industrial preparation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Lightweight flexible pre-printed color corrugated paper board and method of making the same

InactiveCN101532270AReduce consumptionReduce weightMechanical working/deformationSpecial paperColor effectColor printing

The invention relates to lightweight flexible pre-printed color corrugated paper board less than or equal to 400 g / m2 and a method of making the same; the paper in the external and internal parts of the corrugated paper board is 125 to 150 grams boxboard; the corrugated base paper with 100 to 150 grams of core paper is sent into the corrugated paper forming module to press into corrugated paper, then two sides of the core paper are coated with a layer of aqueous bond layer; then the 125 to 150 grams external and internal paper is compounded on edges of corrugations at two sides of the core paper, then sent into the drying tunnel to bake such that the aqueous bond layer forms the solid support layer. The invention has the advantages that: firstly, the paper board uses three-layer corrugated paper board to replace the five-layer corrugated paper board, which has little material consumption, light weight and high strength; secondly, the paper board makes the color effects of the corrugated paper like the high-level color printing effect similar to offset printing; thirdly, the paper board ensures that the strength of the corrugated paper board and the paper box formed therethrough are not damaged.

Owner:绿成包装集团有限公司

Alkali-free accelerator for additive manufacturing buildings, structures or components thereof

Owner:王宇青

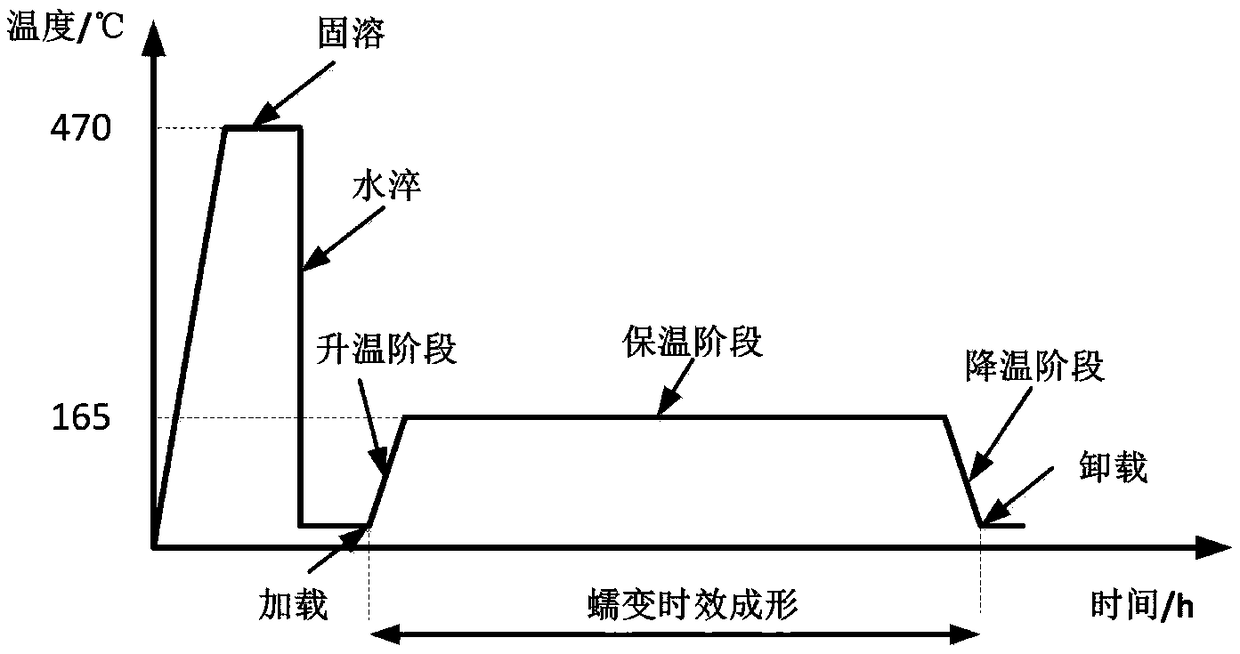

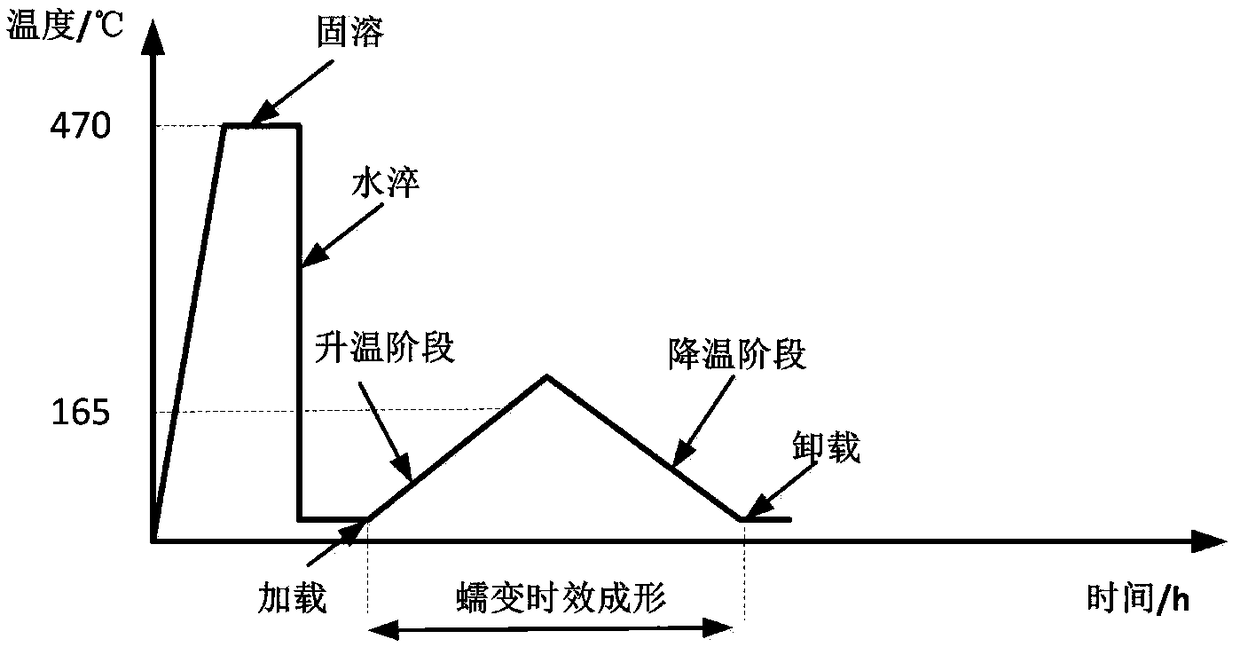

Al-Zn-Mg-Cu series aluminum alloy plate non-isothermalefficientcreep aging forming method

The invention discloses an Al-Zn-Mg-Cu series aluminum alloy plate non-isothermal efficient creep agingforming method. In the process of creep aging forming, a reasonable non-isothermal aging system is adopted and combined withcreep deformation to realize forming and property-formingintegral manufacture of an aluminum alloy complexcomponent. The Al-Zn-Mg-Cu series aluminum alloy plate non-isothermal efficient creep agingforming method comprises the main steps that firstly a plate is subjected to solid solution treatment, and is water-quenched immediately; after being placed at an indoor temperature for certain time, the plate is fixed and loaded on a forming mold; and the plate is heated from the indoor temperature to a highest temperature for creep aging according to a certain heating rate, then the plate is cooled down to the indoor temperature according to the same rate, and finally the plate is unloaded. Compared with a traditional creep aging forming process comprising three stages of temperature rising, temperature preserving and temperature falling, the Al-Zn-Mg-Cu series aluminum alloy plate non-isothermal efficient creep agingforming method only comprises a temperature-rising process and a temperature-falling process, and has no along-time temperature-preserving process, and total forming time is less than the time for traditional creep aging forming comprising an isothermal stage; and on the premise of ensuring a same forming effect, a production period is greatly shortened, the forming efficiency is improved, and the production cost is saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

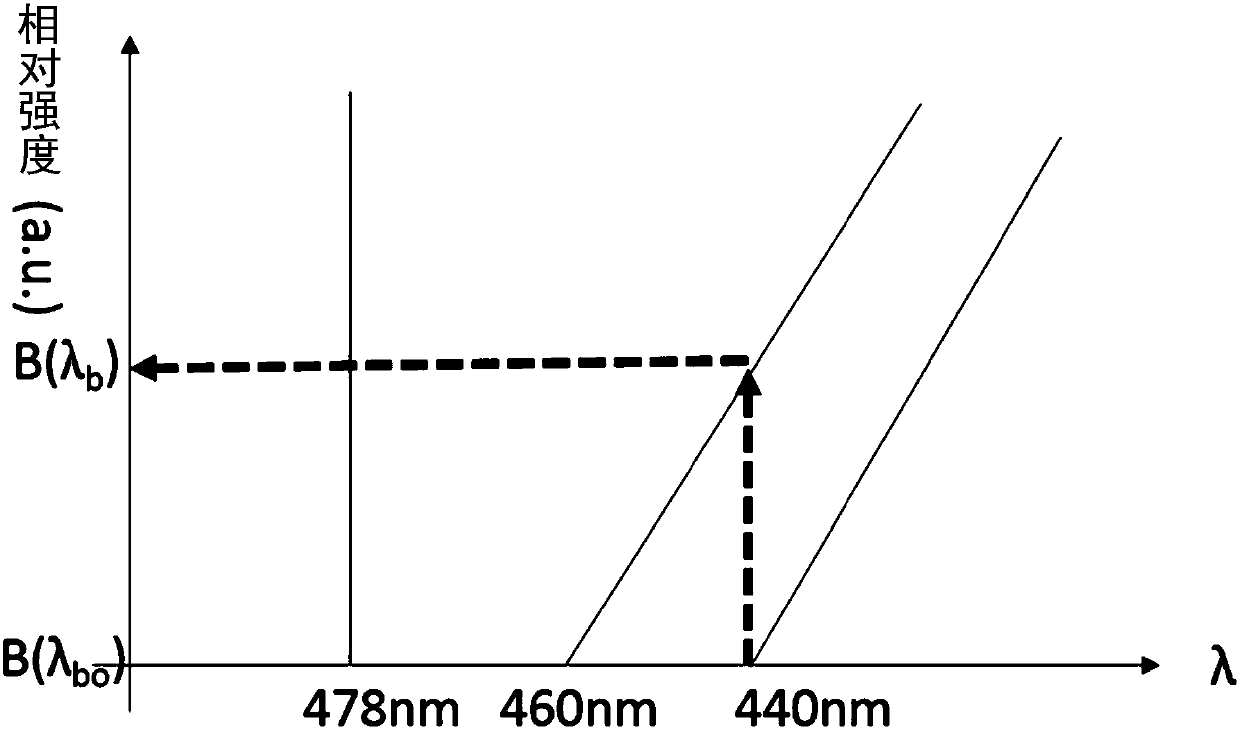

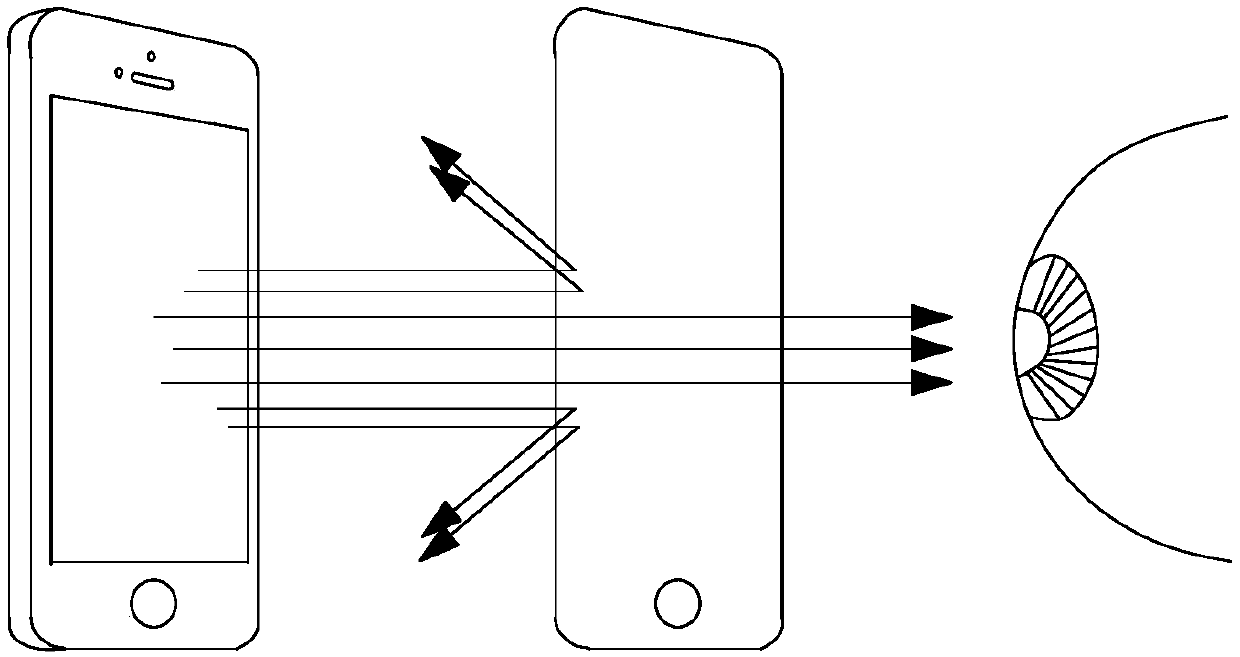

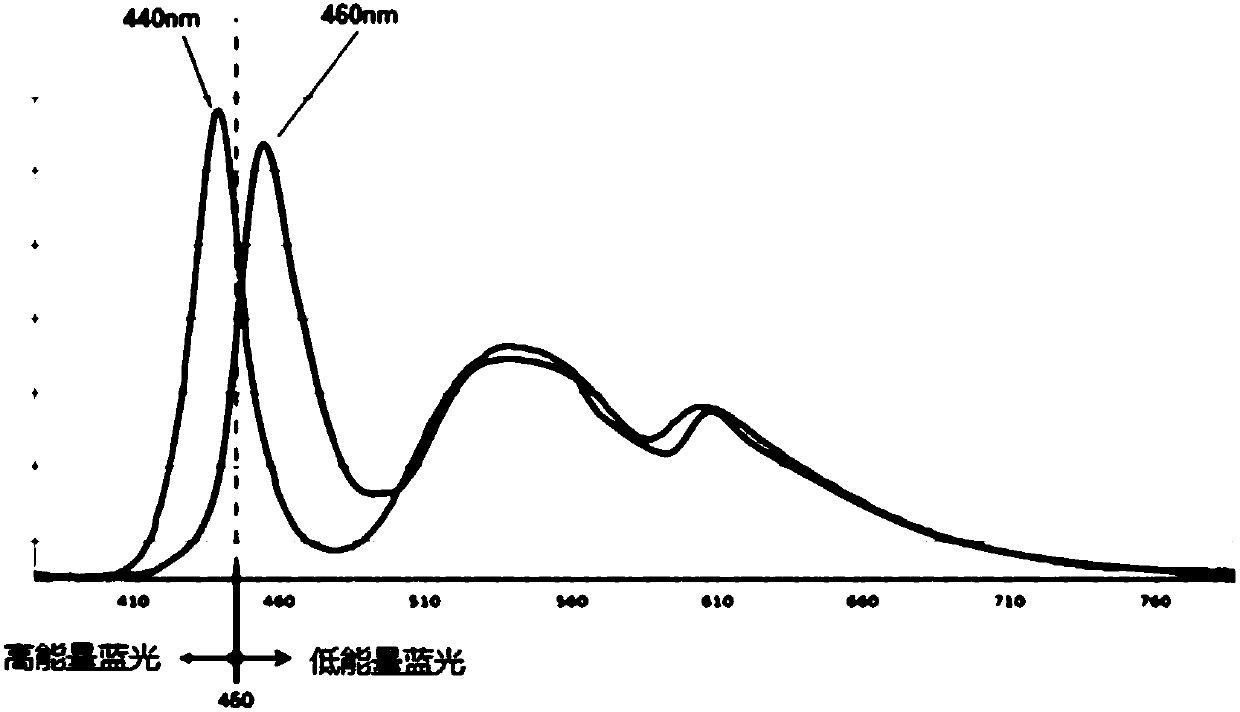

Display device and display driving method

The invention discloses a display device and a display driving method. The display device comprises a backlight module, a display panel arranged at a light outgoing surface of the backlight module, ablue light source arranged in the backlight module and a display driving circuit arranged on the display panel, and is characterized in that the first blue light wavelength of the blue light source isgreater than 440nm; the display driving circuit stores a blue light gamma curve of the blue light source; and the display driving circuit corrects the blue light source according to the blue light gamma curve. The display device can reduce influences imposed on the eyesight by blue light and improve the display image quality at the same time.

Owner:HKC CORP LTD

Method for bleaching fibrous articles

InactiveCN1673443AAvoid embrittlementPrevent hardeningNon-surface-active detergent compositionsBleaching apparatusFiberOxidizing agent

In a method for bleaching fibrous articles by impregnating the fibrous articles with oxidizing or reducing agent solutions and irradiating the impregnated fibrous articles with ultraviolet or visible light, the oxidizing or reducing agent solutions are re-added one or more times to the fibrous articles while they are being irradiated with ultraviolet or visible light.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

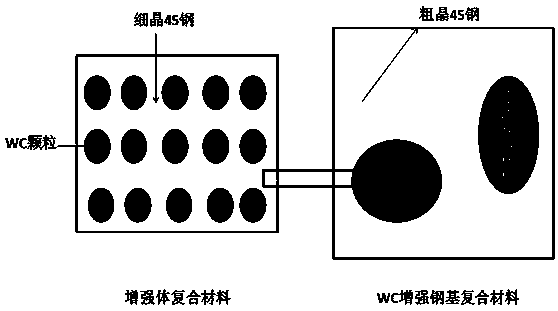

Wolfram carbide particle reinforcement base steel composite material and preparation method

ActiveCN107774984AImprove fracture toughnessImprove overall performanceWear resistantVolume fraction

The invention discloses a wolfram carbide particle reinforcement base steel composite material and a preparation method, and belongs to the technical field of wear-resistant material preparation. Thecomposite material comprises a reinforcement body and a base body. The reinforcement body is of mixed powders of wolfram carbide particles and 45 steel metal powders, the base body is of coarse-grain45 steel metal powders, wherein the volume fraction of the 45 steel metal powders in the reinforcement body is 10-30%, and the volume fraction of the wolfram carbide particles in the reinforcement body is 70-90%. The preparation method comprises the steps that firstly, ball-milling is conducted to the mixed powders of wolfram carbide particles and 45 steel metal powders, the mixed powders after the ball-milling and the coarse-grain 45 steel metal powders are further mixed, and then the ball-milling is further performed, and then compression is performed, finally vacuum sintering is performed,and the wolfram carbide particle reinforcement base steel composite material is obtained. The preparation method is easy, the structure effect of the composite material is fully considered, the volumefraction of the reinforcement particles to the composite material is larger, the reinforcement particles are evenly distributed, breaking tenacity of the composite material is improved, strength is almost no loss, and shock resistance and oxidation resistance are better.

Owner:KUNMING UNIV OF SCI & TECH

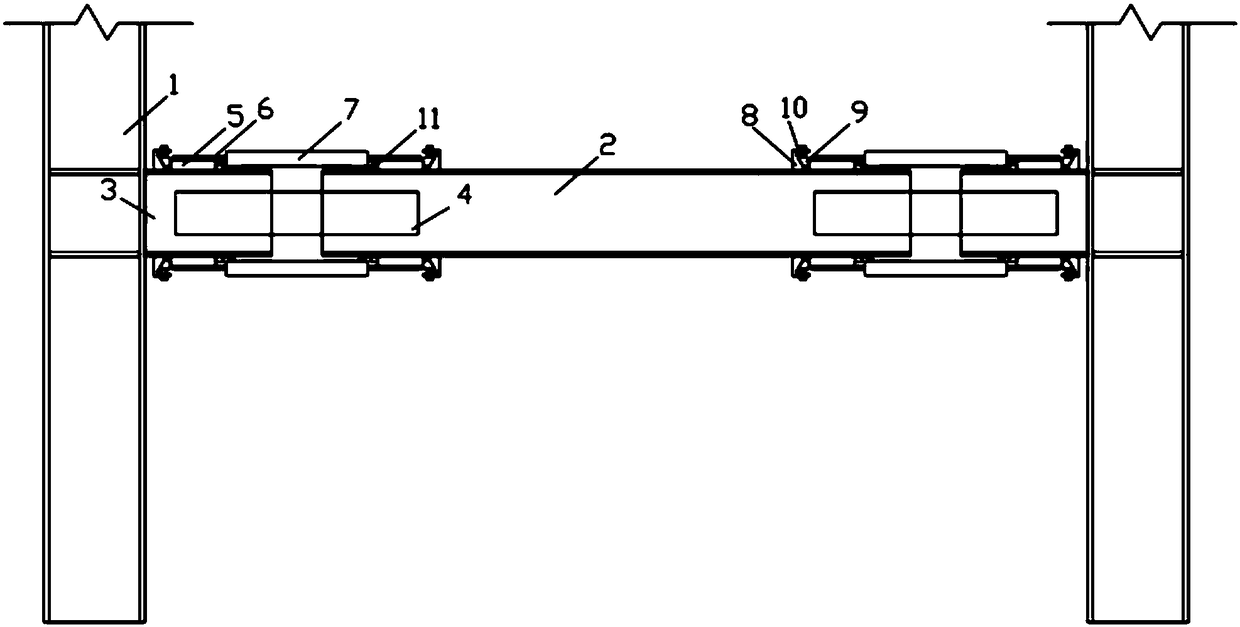

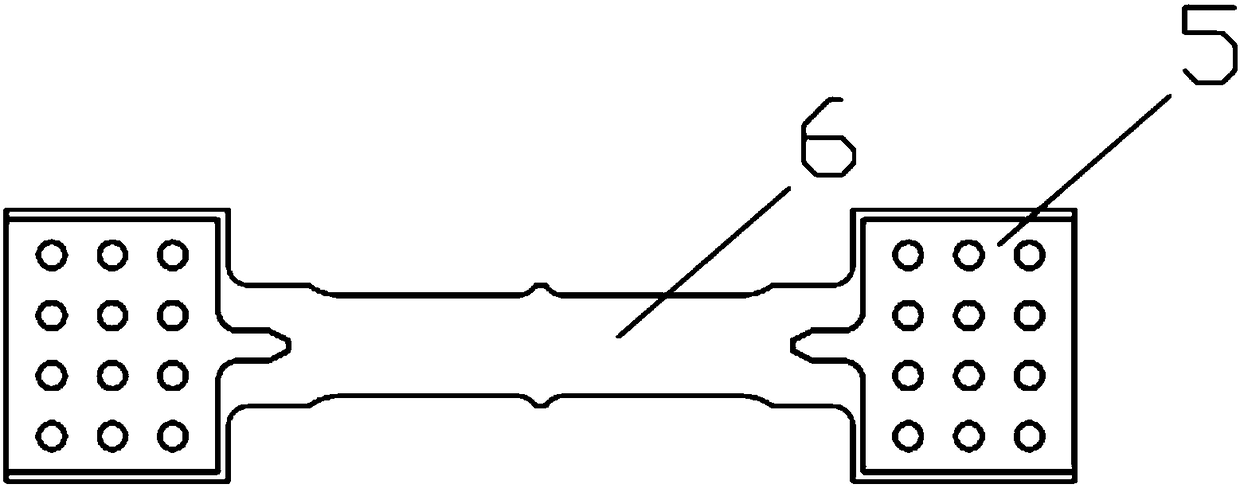

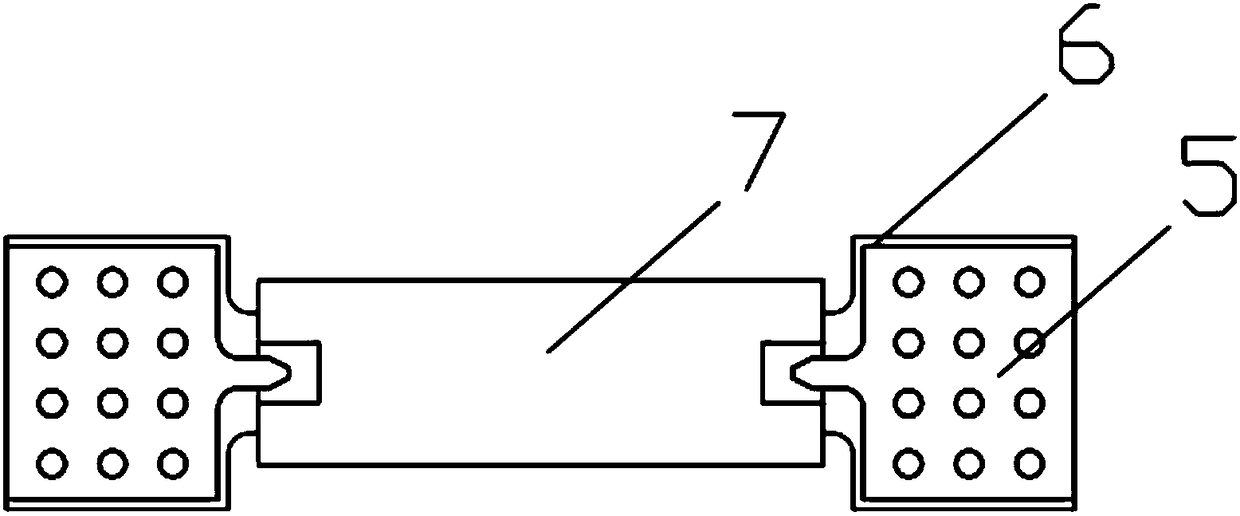

Novel assembled energy-consuming steel frame

ActiveCN108222250ANo loss of strengthImprove energy consumptionProtective buildings/sheltersPhotovoltaic energy generationSteel frameOut of plane

The invention provides a novel assembled energy-consuming steel frame which comprises a column, a long beam section, a short beam section and an energy-consuming section. The energy-consuming steel frame is connected with the long beam section and the short beam section to achieve the assembling ability of the steel frame. The energy-consuming section comprises a flange connector and a web connector, and a connector steel web yields to dissipate energy under an earthquake effect. A rectangular steel tube is arranged outside the flange connector to prevent deformation out of plane of the flangeconnector, and the whole structure has stable bearing capacity and excellent energy-consuming capacity. Shearing resistance devices are arranged at the two ends of a base plate of the flange connector to prevent the flange connector from slipping, and the energy-consuming performance of the energy-consuming section is guaranteed. Under the earthquake effect, the main body structure of the novel assembled energy-consuming steel frame always keeps elasticity, plastic deformation is controlled in the energy-consuming section, and the structure is restored after the energy-consuming section is replaced after earthquake. The novel assembled energy-consuming steel frame has excellent energy-consuming capacity and stable bearing force, and can achieve quick restoration after earthquake.

Owner:DALIAN UNIV OF TECH

Method for preparing waterproof and high-strength oil well plugging agent through miniemulsion method

The invention relates to a method for preparing a waterproof and high-strength oil well plugging agent through a miniemulsion method. The method includes: dissolving ammonium persulfate in deionized water, and then disposing the deionized water into a reactor at temperature of 70-75 DEG C; adopting modes of mechanical stirring and ultrasonic treating to introduce a ketone-hydrazide crosslinking system and a fluorine-containing monomer into an emulsion; preparing a plugging agent through a miniemulsion polymerizing method, dropwise adding the emulsion and initiator water solution for thermal reaction for 2h, cooling, using ammonia water to adjust pH to 7.5-8.5, adding a certain amount of adipic dihydrazide, stirring and discharging to obtain the oil well plugging agent. The oil well plugging agent is prepared by adopting a mode of miniemulsion polymerizing, so that under the condition of same consumption, strength of downhole crack plugging can be ensured, and existence of a lot of water exerts small influence on plugging strength of the oil well plugging agent.

Owner:PETROCHINA CO LTD

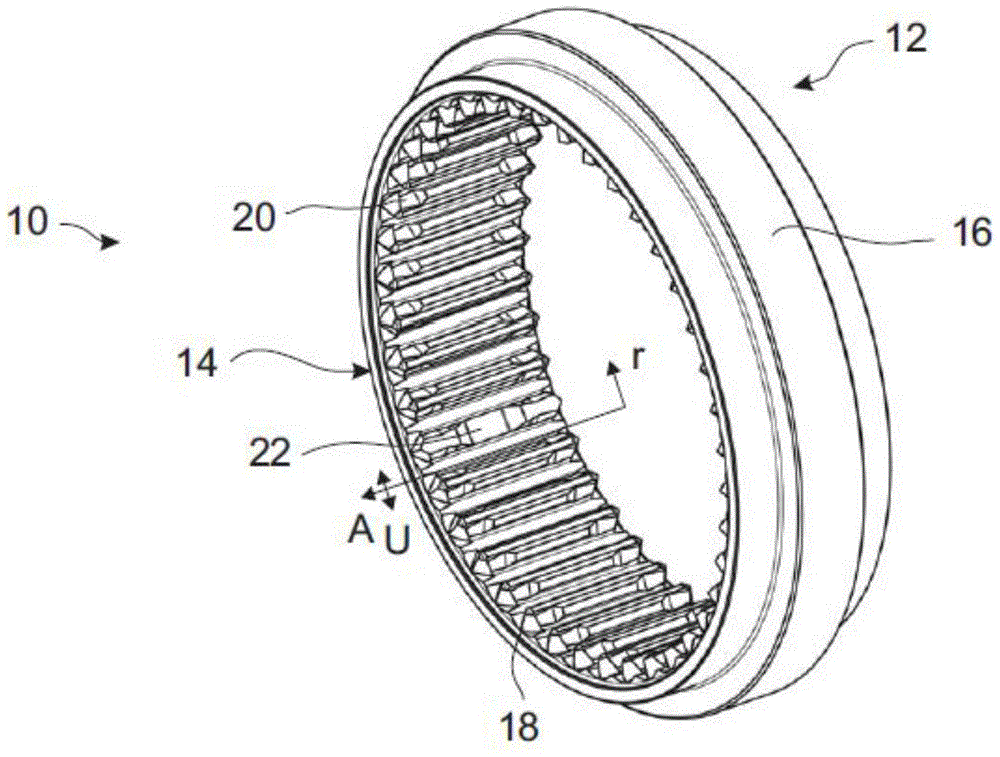

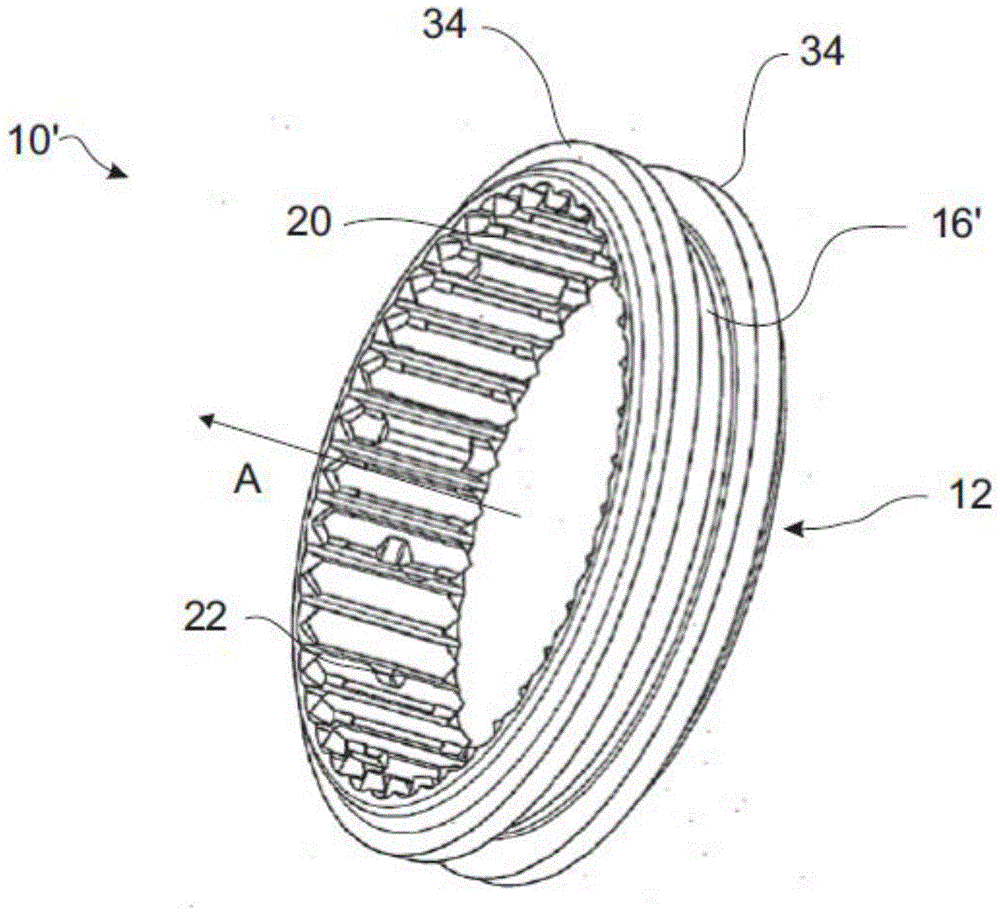

Method for making slide sleeve ring

The invention relates to a method for making a slide sleeve ring; metal powders are sintered so as to form the slide sleeve ring (12) through moulding; pressed product (10) can be made under pressure effect in a pressing process, can be cut and processed under pressing fixed state, and is sintered so as to form the moulding piece.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Seasoning for salting beef

The invention discloses a seasoning for salting beef. The seasoning for salting the beef comprises the following raw materials in parts by weight: 5 to 10 parts of ginger powder, 5 to 10 parts of garlic powder, 3 to 6 parts of a yeast extract, 3 to 5 parts of a lemon extract, 15 to 25 parts of traditional Chinese medicinal powder, 5 to 15 parts of proteolytic enzyme, and 1 to 5 parts of a fresh strengthening agent. The seasoning for salting the beef is obtained by mixing the raw materials in proportion. A using method comprises the following steps: cleaning the beef; mixing 20 to 30 g of the seasoning and 50 to 100 g of water uniformly, wherein 20 to 30 g of the seasoning is used for 500 to 1500 g of the beef; coating the beef with the mixture; salting for 10 to 15 minutes, and performing the cooking processes, such as stewing, boiling, deep frying and frying. The seasoning for salting the beef disclosed by the invention does not contain the pungent tastes of spiciness, piquancy, sourness and the like; the beef is easy to cook thoroughly, but the sense of strength and the freshness cannot lose along with the prolongation of time; the prepared beef is fresh without special smell, and is delicate in taste.

Owner:杨建民

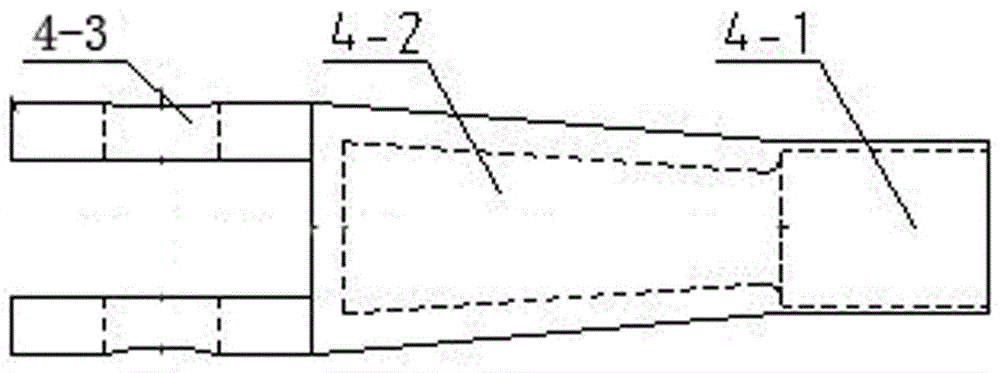

A plug-in wire rope joint and its manufacturing method

ActiveCN105156588BNo loss of strengthRopes and cables for vehicles/pulleyTextile cablesWeld seamFiller metal

The invention relates to a plug-in steel wire rope connector which comprises a casting body and a steel wire rope. The end of the steel wire rope is inserted into an opening of the casting body and welded together. The casting body is a closed type casting body with an opening formed in the end. An inner cavity of the opening end of the casting body is divided into an inverted-cone cavity body and a filling shrinkage cavity body. The inverted-cone cavity body is a cone opening gradually shrunk from inside to outside. The filling shrinkage cavity body is formed in the outer end of the inverted-cone cavity body. The inner diameter of the filling shrinkage cavity body is larger than the inner diameter of the inverted-cone cavity body at the transition portion of the filling shrinkage cavity body and the inverted-cone cavity body. According to the plug-in steel wire rope connector, as the casting body is arranged in a closed form with one end open, the filling shrinkage cavity body is designed in the end, before the end of the steel wire rope is inserted into the casting body, brazing filler metal is placed into the casting body, and the brazing filler metal in the filling shrinkage cavity body is shrunk due to the fact that liquid brazing filler metal in the inverted-cone cavity body is cooled and turned into a solid, so that most brazing filler metal flows into the inverted-cone cavity body, and a welding seam structure basically flawless in the inverted-cone cavity body is formed.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Packless casting temperature-resistant coating

InactiveCN101596575ANo accumulationImprove high temperature strengthFoundry mouldsFoundry coresHydrogen phosphateAqueous solution

A packless casting temperature-resistant coating is characterized in that the coating is prepared by the following components by weight percent: 60-70% of aluminium hydrogen phosphate, 0.01-0.05% of wetting agent, 0.001-0.005% of methylene blue and the allowance water and the specific gravity of the prepared solution is 1.2-1.3. The invention has the advantages that the new coating is aqueous solution without any filler so as to avoid all the problems in preparation, storage and use; coating can not be stacked so that castings without surplus or with little surplus can be obtained easily; the effects of avoiding burr, veining, sand penetration and sintering of the coating are incomparable to traditional coatings; blowhole is effectively prevented; the production cost can be promoted to reduce.

Owner:徐俊伟

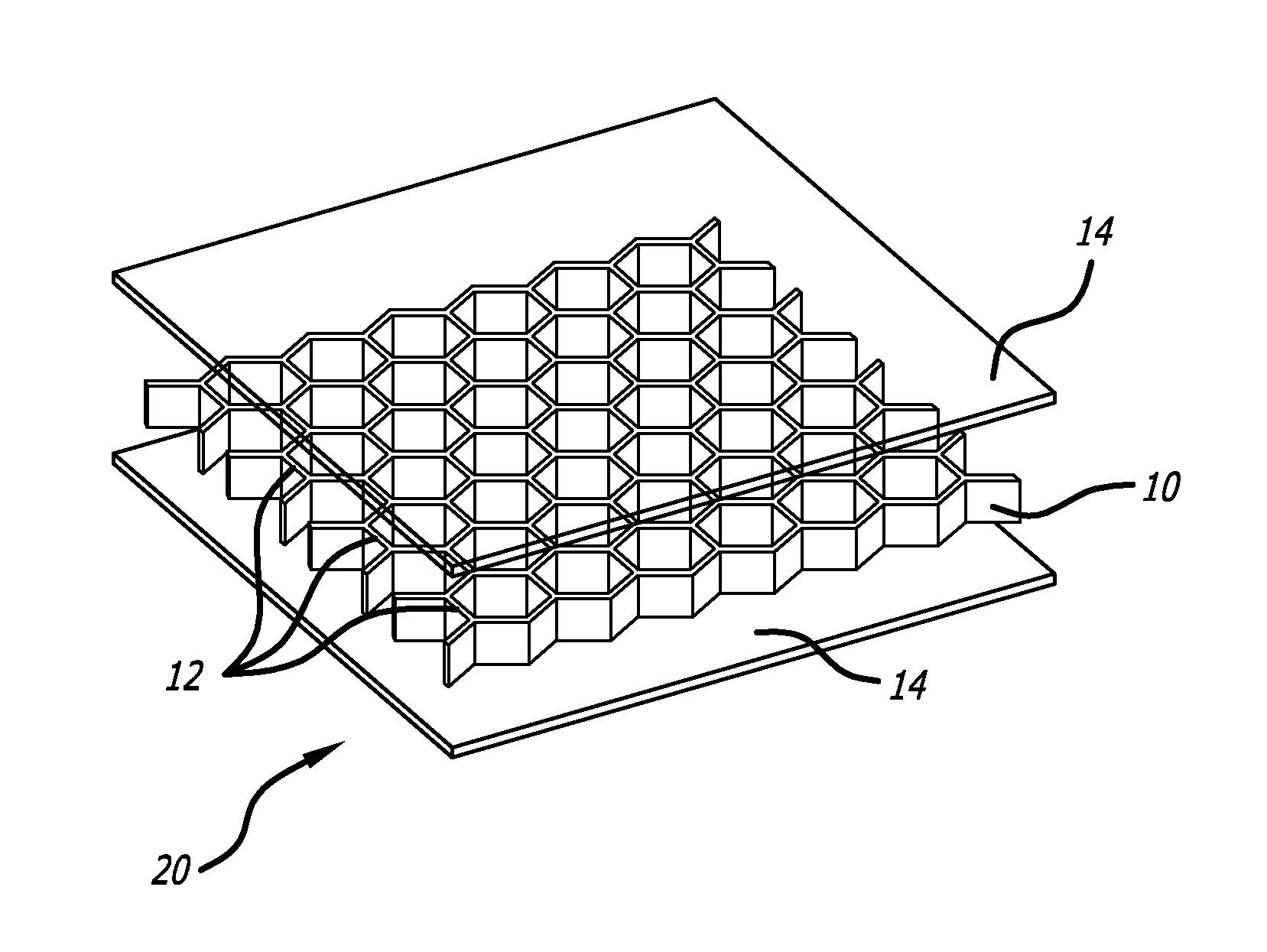

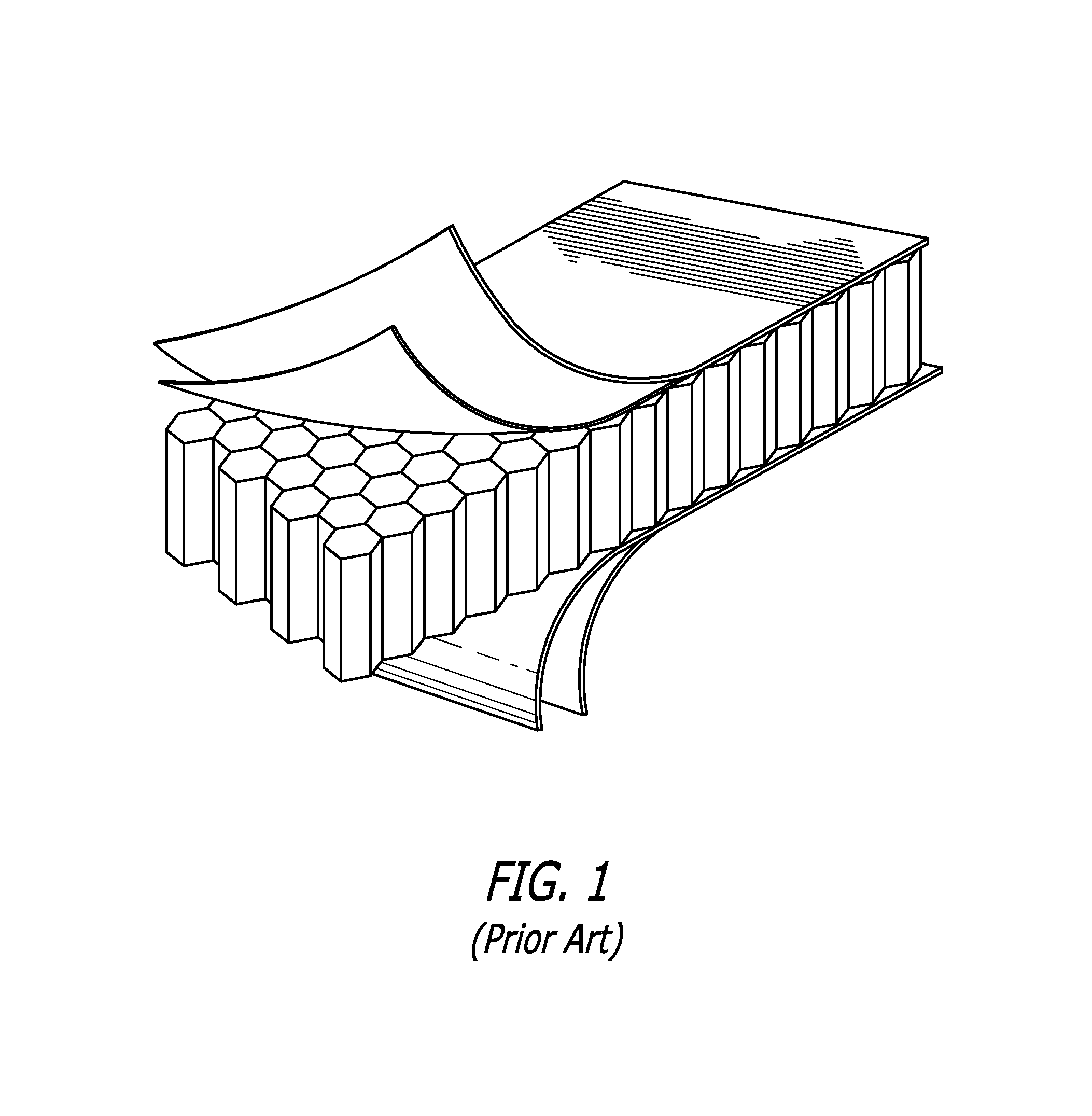

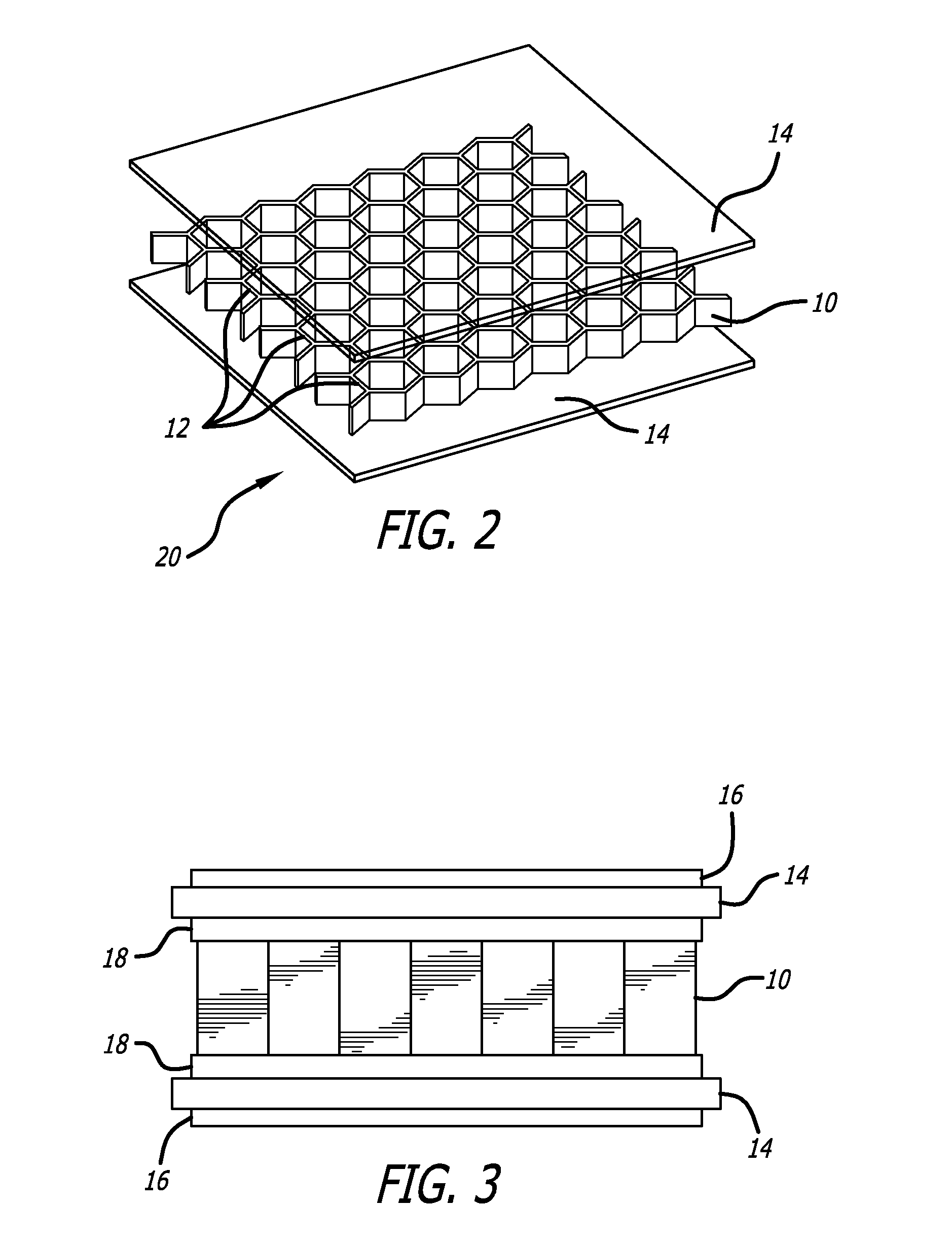

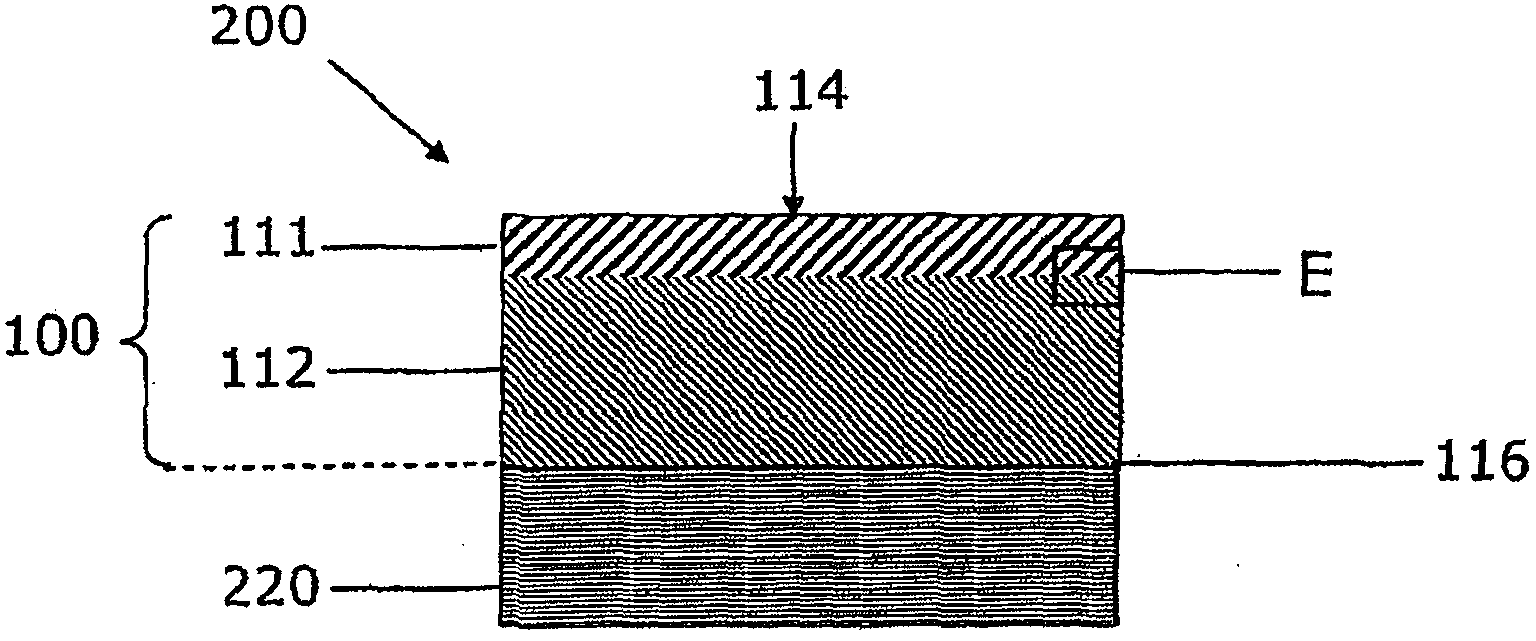

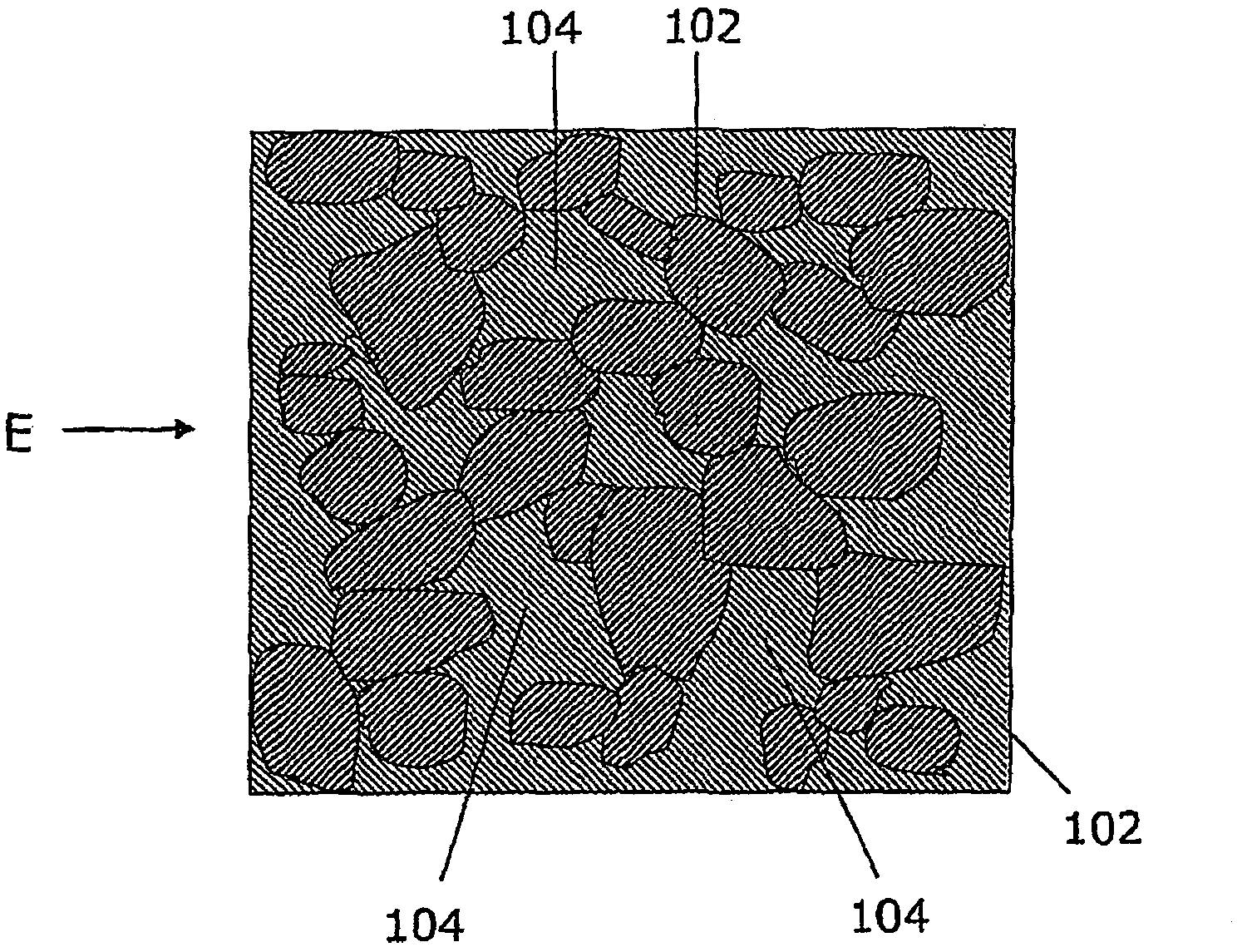

Composite sandwich panel with differential resin layers

ActiveUS9573338B2Improving weight characteristicNo loss of strengthSynthetic resin layered productsLaminationHoneycombEngineering

A composite panel includes a honeycomb core sandwiched by a pair of skins that are attached directly to the core with no separate adhesive layer. The skins are impregnated with a resin material that is unevenly distributed between first and second surfaces, and direct contact is established between the surfaces with the greater resin distribution and the core, reducing weight and eliminating the manufacturing step of incorporating an adhesive layer therebetween.

Owner:BE AEROSPACE INCORPORATED

Method for enhancing flexibility of pure cotton fabrics

InactiveCN108978202AGood flexibilityStable soft statePhysical treatmentGrip property fibresEngineeringVapor pressure

The invention discloses a method for enhancing flexibility of pure cotton fabrics and relates to the technical field of pure cotton fabrics. The method for enhancing flexibility of pure cotton fabricscomprises the following steps: (1) adding the pure cotton fabrics into water for heat treatment, and drying; (2) soaking the pure cotton fabrics with water to form a dripless state, tiling the fabrics on a flat worktable, flattening the pure cotton fabrics by a flat plate, and hanging up; (3) adding a soft preparation into water to be uniformly mixed, atomizing by an atomizer, and spraying onto the erected pure cotton fabrics; (4) baking the pure cotton fabrics sprayed with the soft preparation by a baker; and (5) seaming the baked pure cotton fabrics under saturated vapor pressure, cooling,tiling on the flat table-top, and heating and drying by using high infrared radiation. The flexibility of the prepared pure cotton fabrics is greatly increased, the fabrics can also maintain excellentflexibility after washing, and the breathability and strength of the pure cotton fabrics are not damaged, so that the wearing comfort is increased.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

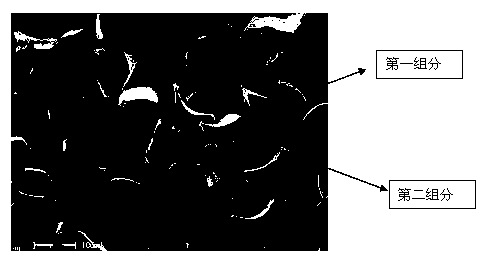

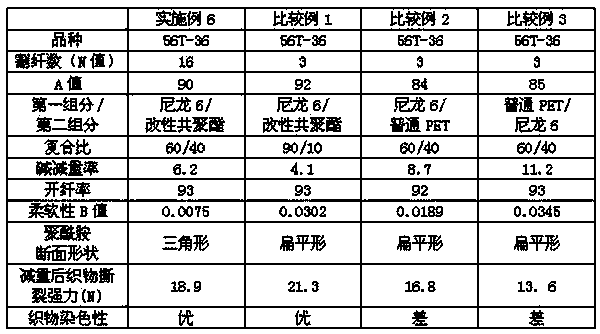

Split type composite fiber and superfine fiber fabric prepared by same

InactiveCN103422190AEliminate fiber formation difficultiesGood alkali resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsCopolyesterSide chain

The invention discloses a split type composite fiber. The fiber is composed of aliphatic polyamide as a first component and modified copolyester as a second component, wherein the second component is the modified copolyester prepared by copolymerizing aliphatic dibasic alcohol as a third monomer and with a side chain and having the carbon atom number of six or less; the second component is distributed on the cross section of the composite fiber in a continuous phase manner and splits the first component, and the first component is distributed on the cross section of the composite fiber in a discontinuous phase manner. The split type composite fiber containing aliphatic polyamide and modified copolyester is obtained by adopting a composite spinning method, and the composite fiber further forms a fabric; after the fabric is subjected to aqueous alkali decrement treatment, the two components can be fully stripped so as to form a superfine fiber fabric; and the superfine fiber fabric can be dyed under a normal pressure, has water absorption and quick-drying properties, soft hand feeling and higher tear strength, and achieves wide application in the clothing field.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

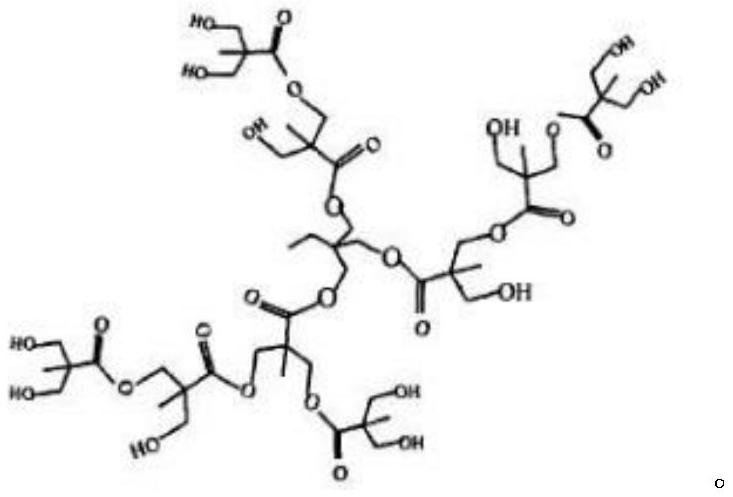

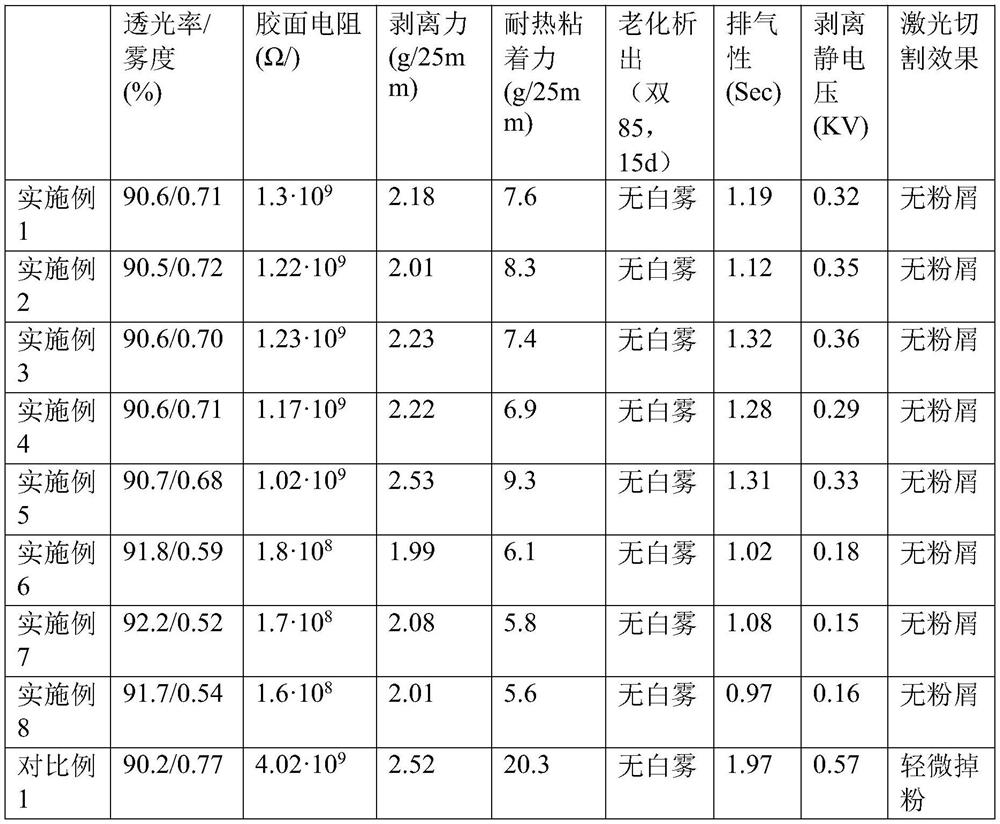

PU protective film for display screen manufacturing process and preparation method of PU protective film

PendingCN114369418AImprove cohesionHigh peel strengthPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesPolymer scienceSide chain

According to the PU protective film for the display screen manufacturing process and the preparation method of the PU protective film, a macromolecular chain is formed and a complex net-shaped structure is constructed through a grafting modification method, and a hyperbranched structure and a fluorine-containing structure are introduced into polyurethane, so that the prepared protective film has relatively good cohesion and relatively high peel strength; the advantages of low-viscosity climbing, no precipitation residue, good exhaust performance, no glue overflow in laser cutting and the like are achieved; allyl glycidyl ether is used as a monomer, anionic ring-opening polymerization and thiol-ene click reaction are utilized to introduce flexible alkyl into a side chain, alkyl functionalized poly (allyl glycidyl ether) in which an antistatic agent is added is prepared, the glass transition temperature of the PU protective film is reduced, the interaction of components in the PU protective film is enhanced, and the antistatic property of the PU protective film is improved. The toughness of the PU protective film can be obviously improved while the strength of the PU protective film is not lost, meanwhile, the surface resistivity of the PU protective film is effectively reduced, and more excellent aging precipitation resistance and antistatic effect are embodied.

Owner:苏州世诺新材料科技有限公司

Ultrahigh-temperature magnesium oxide fibre product and preparation method thereof

ActiveCN104529487AEasy to make glueLow costInorganic material artificial filamentsFilament/thread formingThermal insulationThermal shock

The invention relates to an ultrahigh-temperature magnesium oxide fibre product and a preparation method thereof. The ultrahigh-temperature magnesium oxide fibre product is composed of magnesium oxide fibres with the diameter of 0.2-30 mu m; the mass content of magnesium oxide is more than or equal to 98%; the density of magnesium oxide is 0.07-3.0g / cm<3>; and the ultrahigh-temperature magnesium oxide fibre product can be prepared into high-temperature-resistant products in shapes of plates, long strips, columns, cylinders and the like according to requirements, and can be used as thermal insulation materials. The fibre product prepared by the invention can be used at 1800-2700 DEG C for a long time; the intensity of the fibre product cannot be lost in the use process; and furthermore, the fibre product can bear high-frequency thermal shock and continuous impact of high-temperature and high-speed air flows.

Owner:SHANDONG UNIV

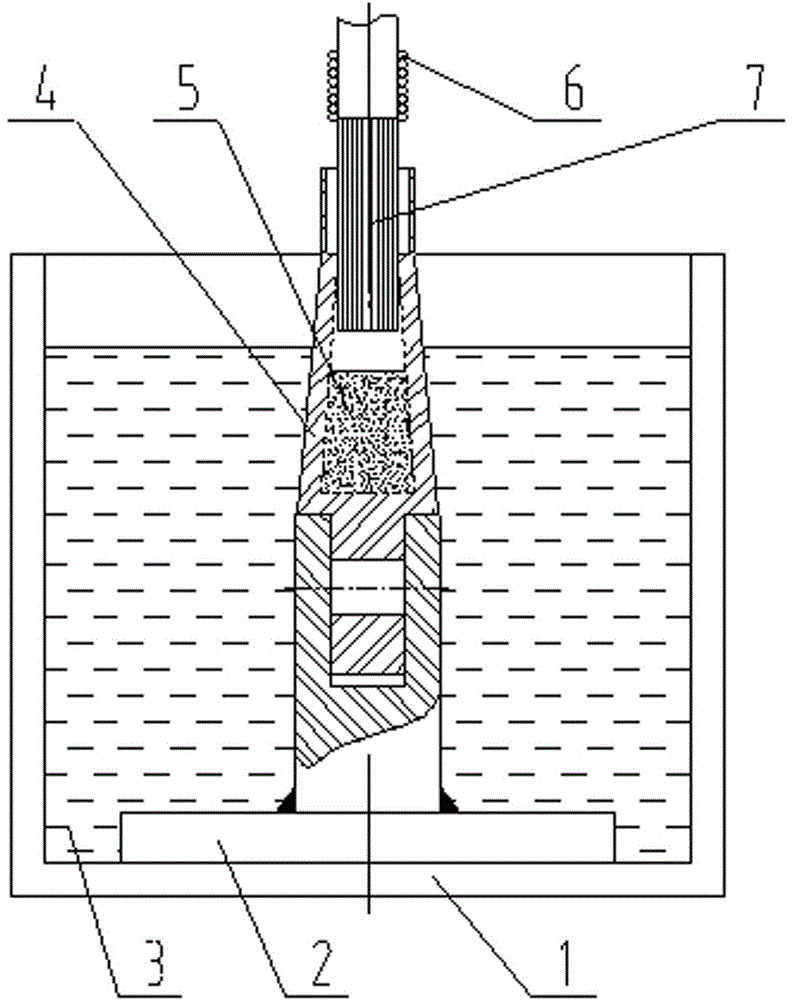

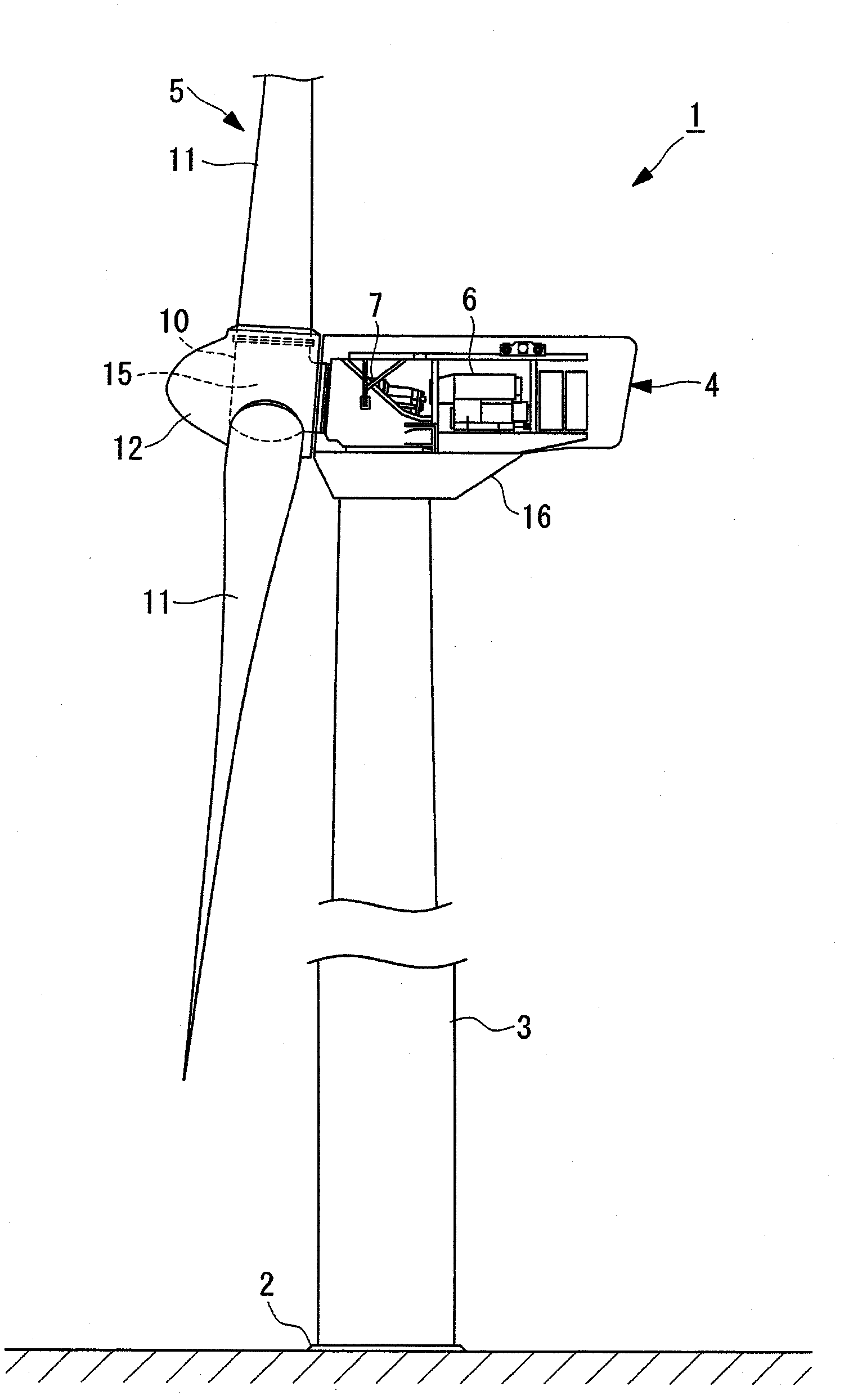

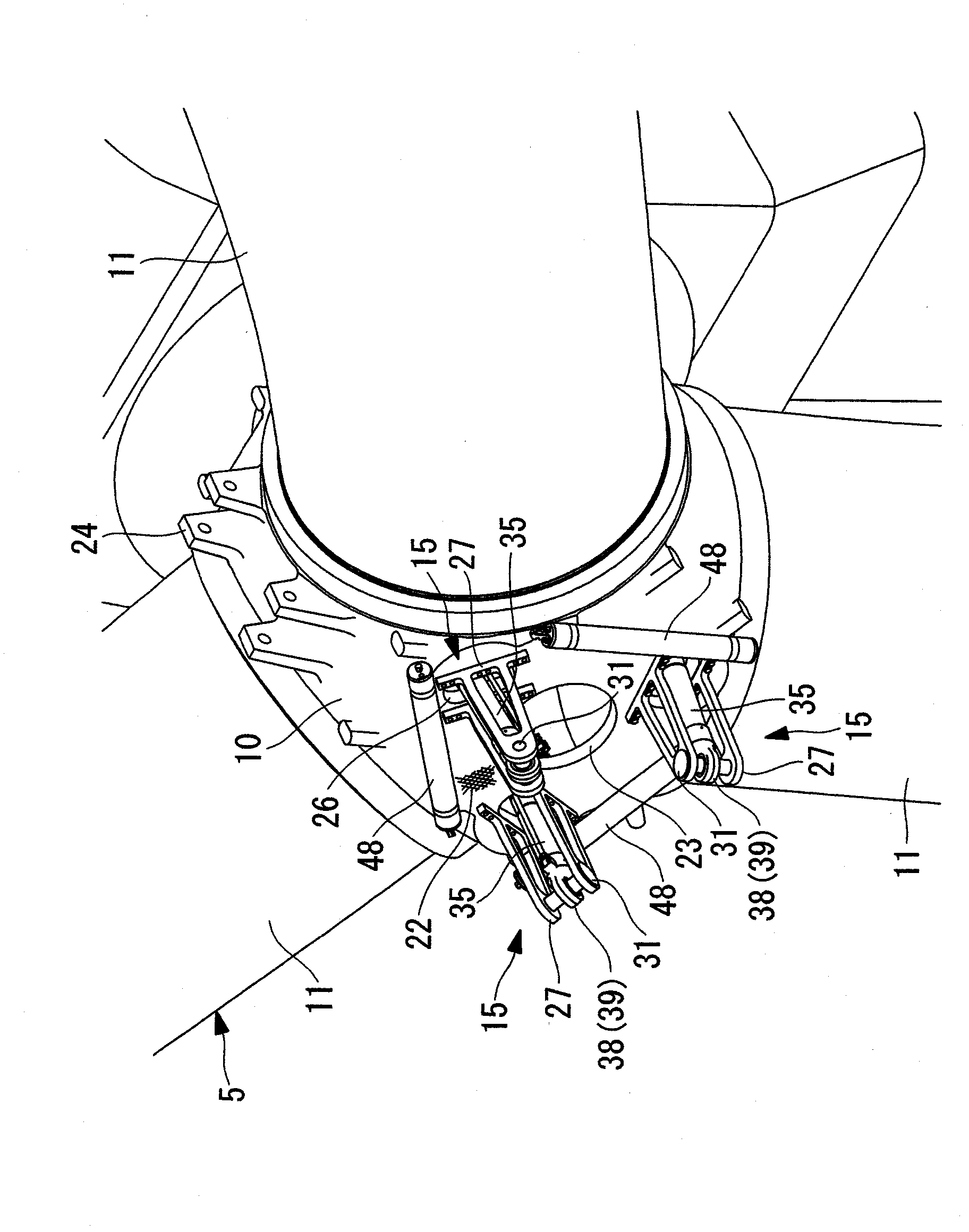

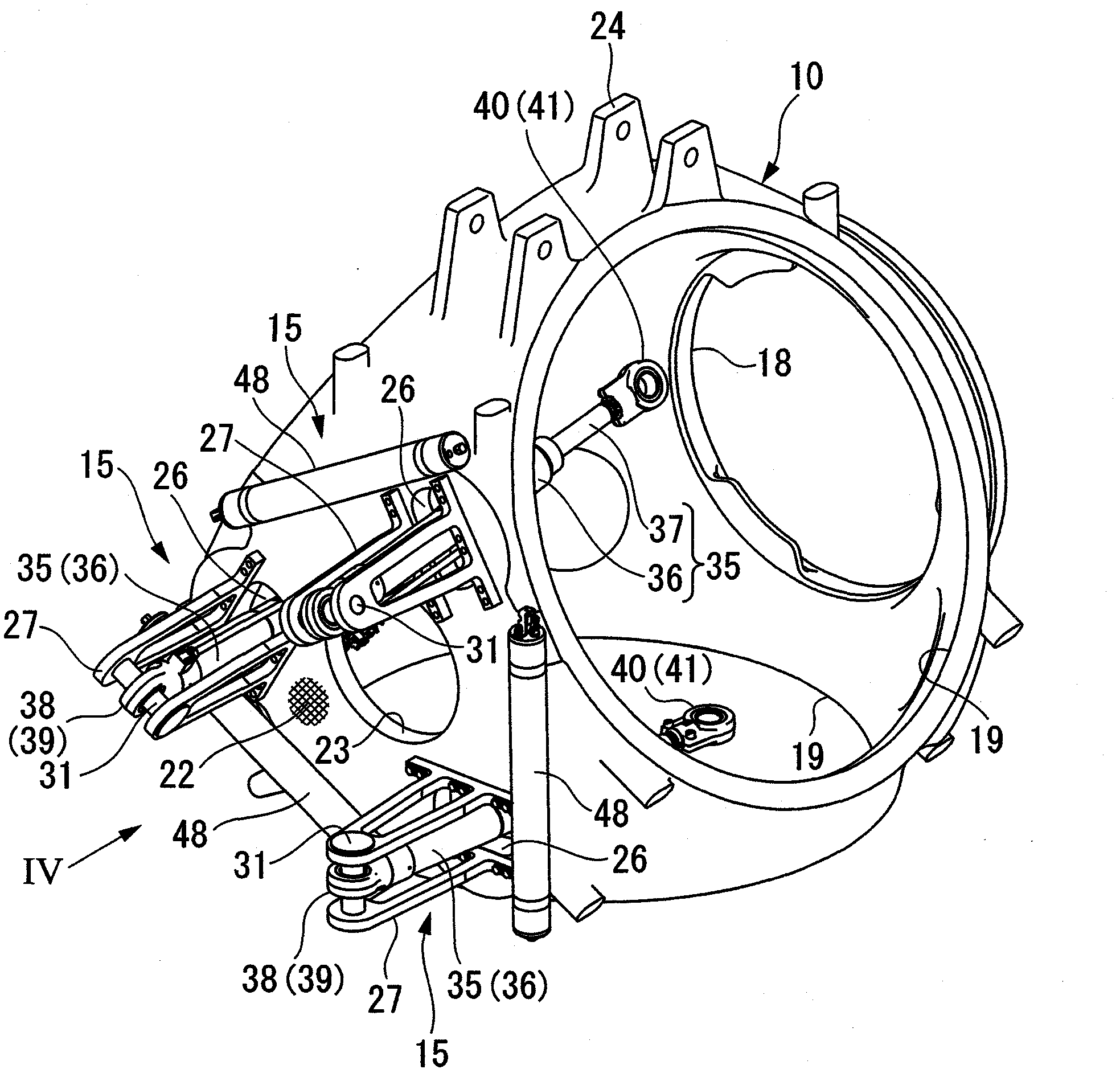

Device for driving pitch of wind turbine blade, rotating wind turbine blade with same, and wind turbine device

InactiveCN102762856ANo loss of strengthSmooth changeWind motor controlEngine fuctionsTurbine bladeSupport point

In order that the pitch angle of a wind turbine blade can be changed using a simple, lightweight, low cost, and highly durable structure without impairing the strength of each portion such as a rotor hub, the present pitch drive device (15) is characterized in comprising: a cylinder support section (27) provided to the rotor hub (10) and having a support point (31) located on the side of the cylinder support section (27) which is opposite the front end surface (22)(non-supported end section) of the rotor hub (10); an eccentric connection point (34) provided at an eccentric position on the root-side end surface (11b) of the wind turbine blade (11); and a cylinder (35) disposed so as to penetrate through the non-supported end section (22) of the rotor hub (10) and configured in such a manner that a connection section (38) provided to the portion of the cylinder (35) which protrudes further outward than the non-supported end section (22) is rotatably connected to the support point (31) through a spherical surface joint (39) and in such a manner that a connection section (40) located on the inner side of the non-supported end section (22) is rotatably connected to the eccentric connection point (34) through a spherical surface joint (41).

Owner:MITSUBISHI HEAVY IND LTD

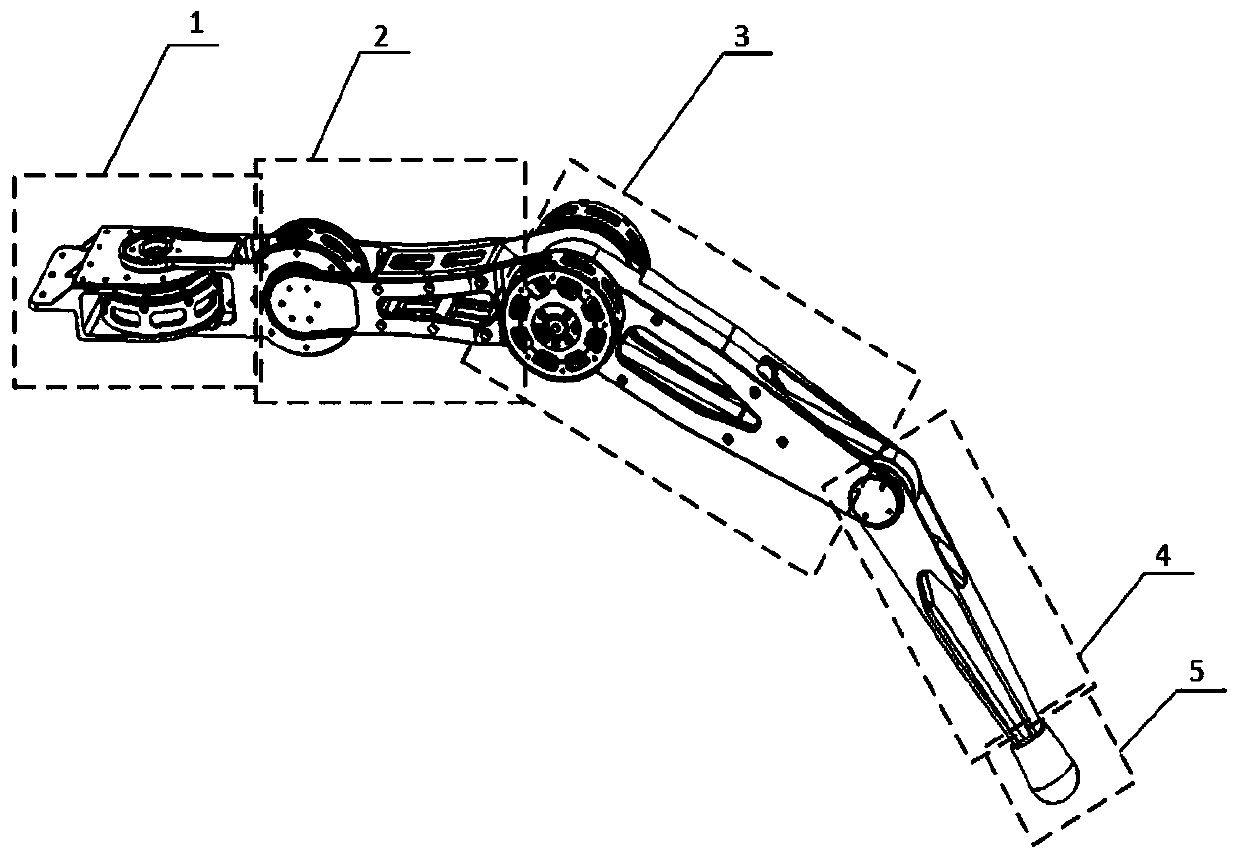

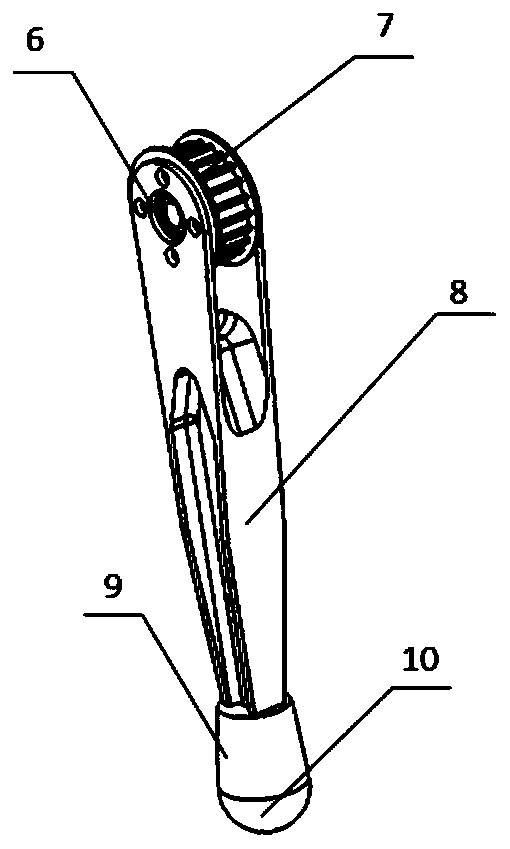

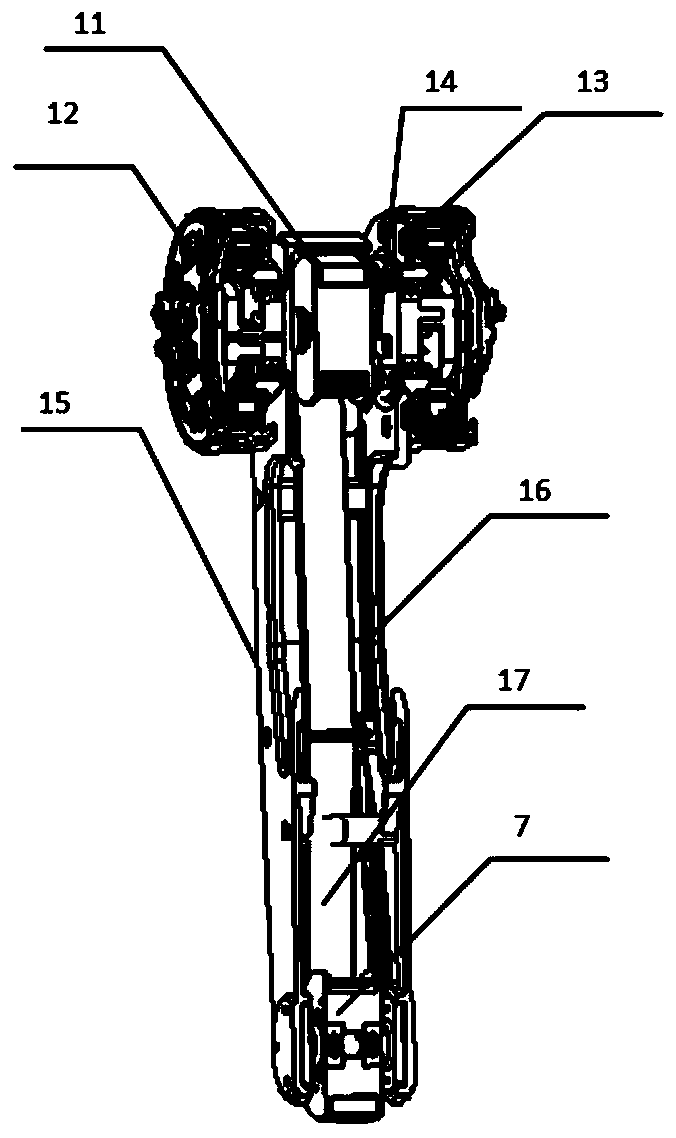

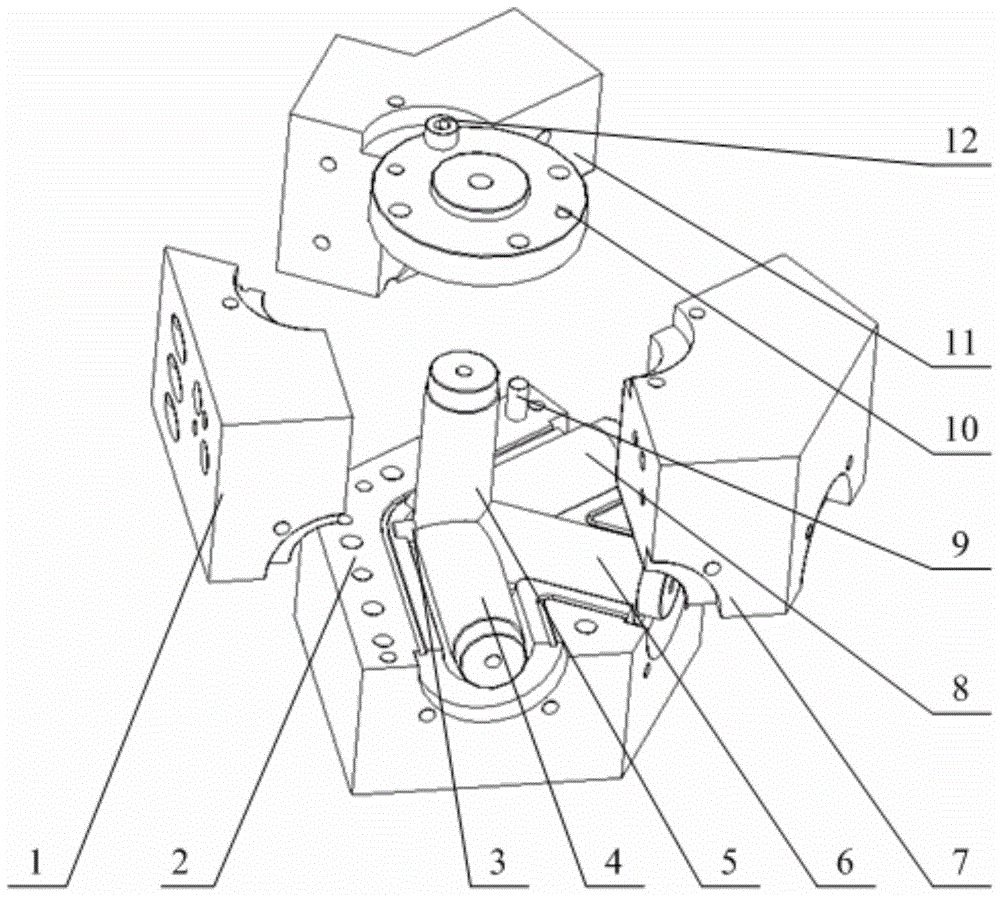

Multi-degree-of-freedom light single-leg mechanism

The invention discloses a multi-degree-of-freedom light single-leg mechanism. The multi-degree-of-freedom light single-leg mechanism comprises a hip joint module, a knee joint module, an ankle joint module, a shin joint and a foot end; the hip joint module, the knee joint module, the ankle joint module, the shin joint and the foot end are connected in sequence; the whole single-leg design mode disclosed by the invention greatly improves the adaptability of the robot legs to complex terrains, improves the dynamic and static stability of a robot, and also improves the integral bearing capacity and control precision of the robot; the single leg with multiple degrees of freedom has flexible movement and light weight; the installation position of a driving motor is closer to the body, so that the problem of high rotational inertia easily generated by a tail end joint is solved, and the movement of the driving mechanism is facilitated; and the single leg has a large movement working space range in the aspects of mechanism movement and power.

Owner:CHANGAN UNIV

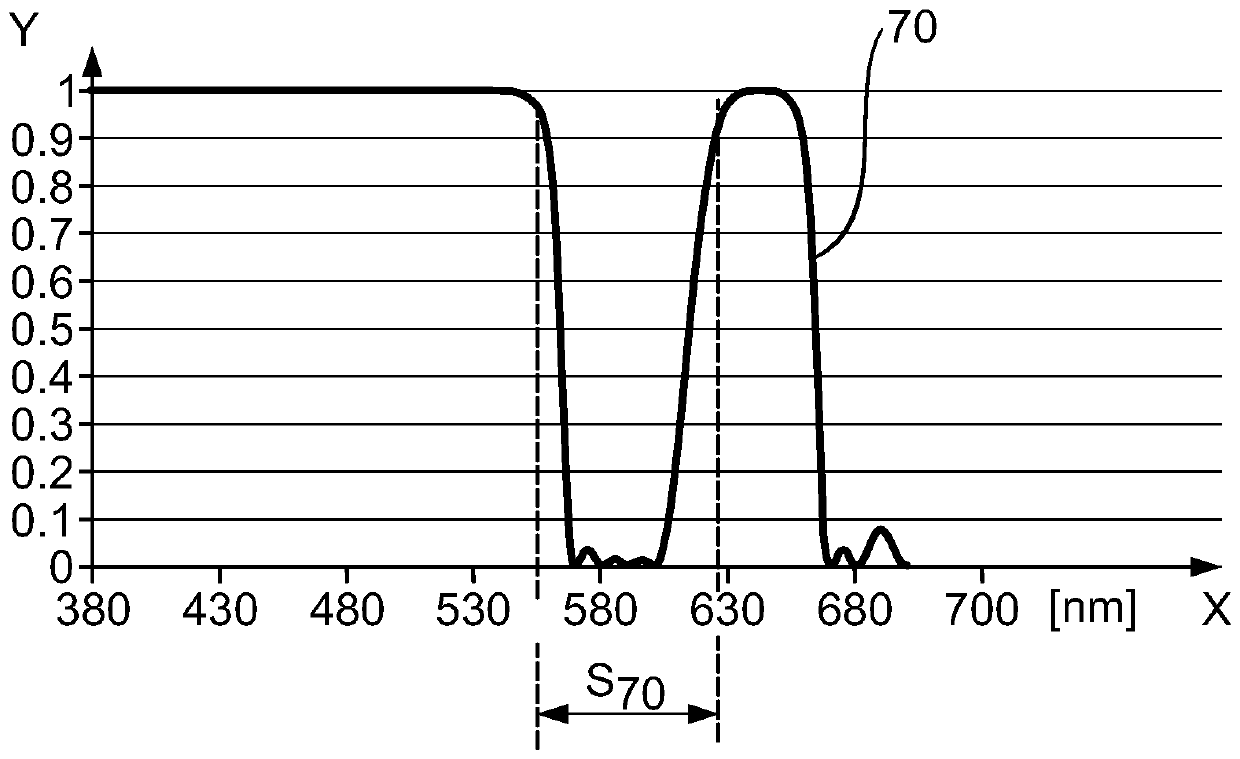

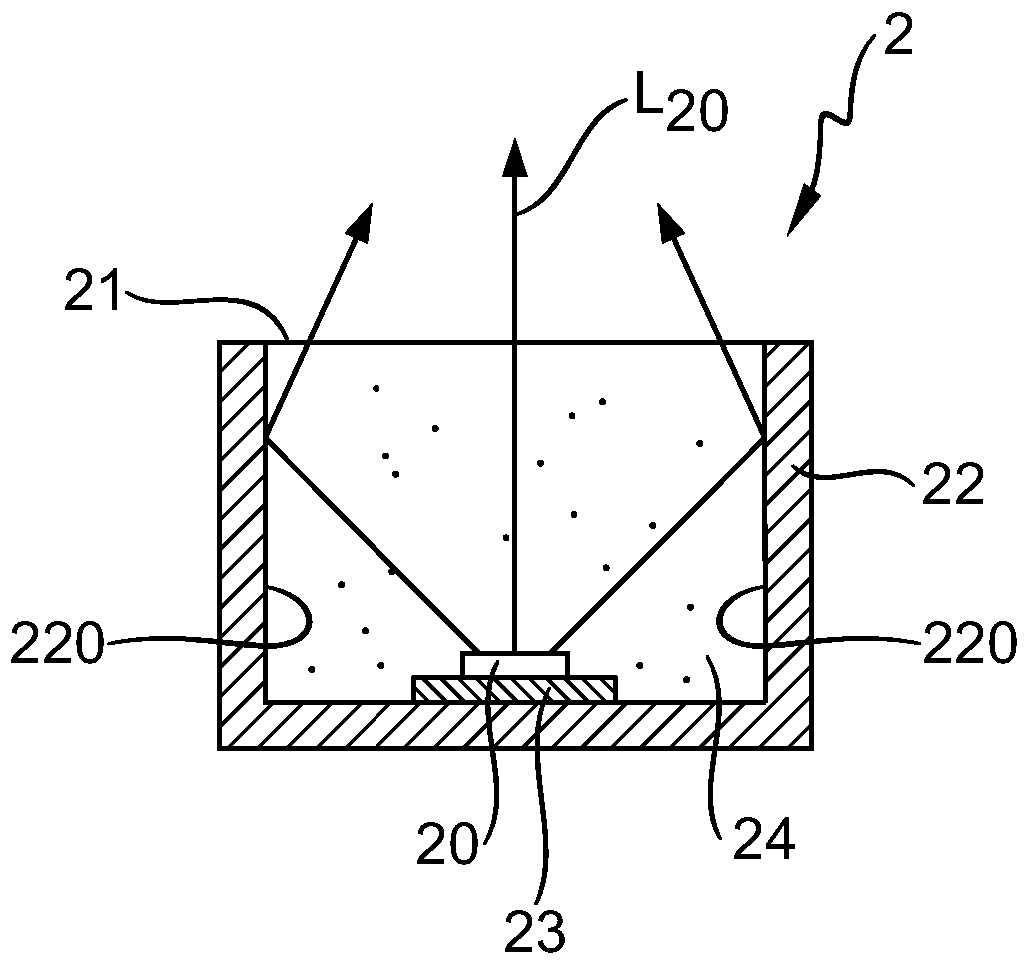

LED lighting unit

PendingCN109906340ADistinct off-white colorNo loss of strengthElectric lightingOptical signallingEngineeringLed illumination

The invention describes an LED lighting unit (1) comprising a container (12) with a number of partially reflective side walls (120); a light exit opening (11) defined by the side walls (120); and a number of light-emitting diodes (10) arranged in the container (12) to emit light (L10) of a first colour (CLED) through the light exit opening (11) during an on-state of the lighting unit (1). The LEDlighting unit is characterized in that the material properties of the partially reflective container side walls (120) are chosen to impart a second non-white colour (CPG, CPY, CPB) to the container side walls (120), and to absorb light in at least one specific region (S40, S41, S60, S70) of the visible spectrum such that light (L120) of the non-white second colour (CPG, CPY, CPB) exits the lighting unit (1) through the light exit opening (11) during an off-state of the lighting unit (1). The invention further describes a method of manufacturing such an LED lighting unit (1).

Owner:LUMILEDS HLDG BV

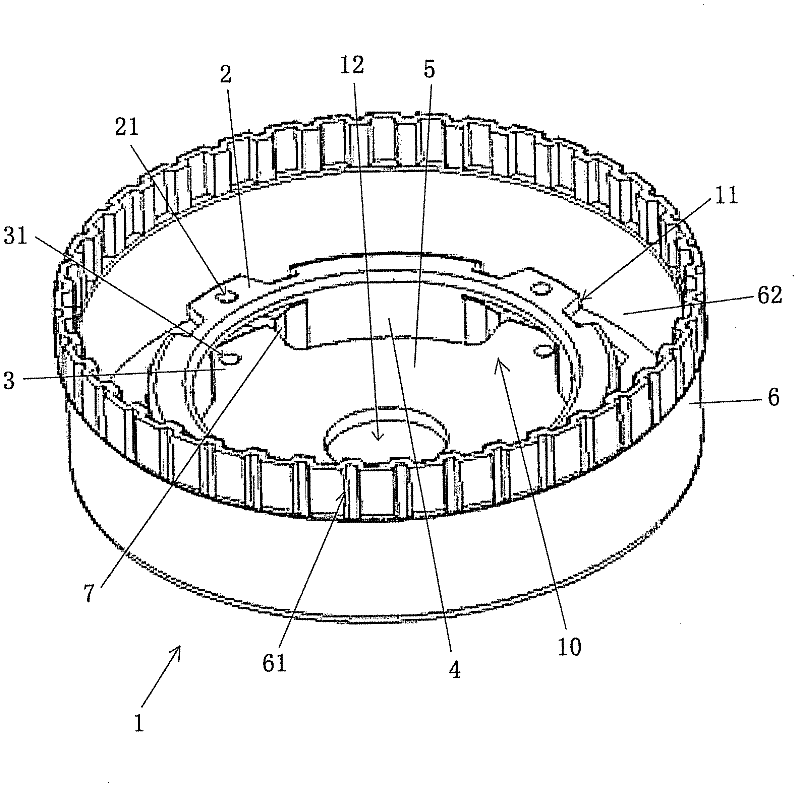

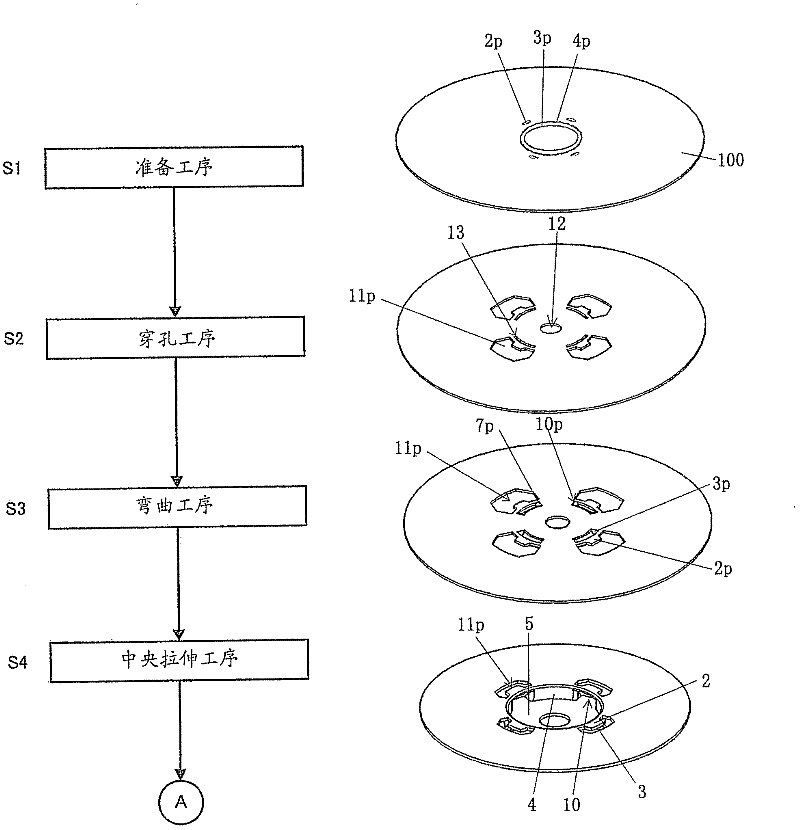

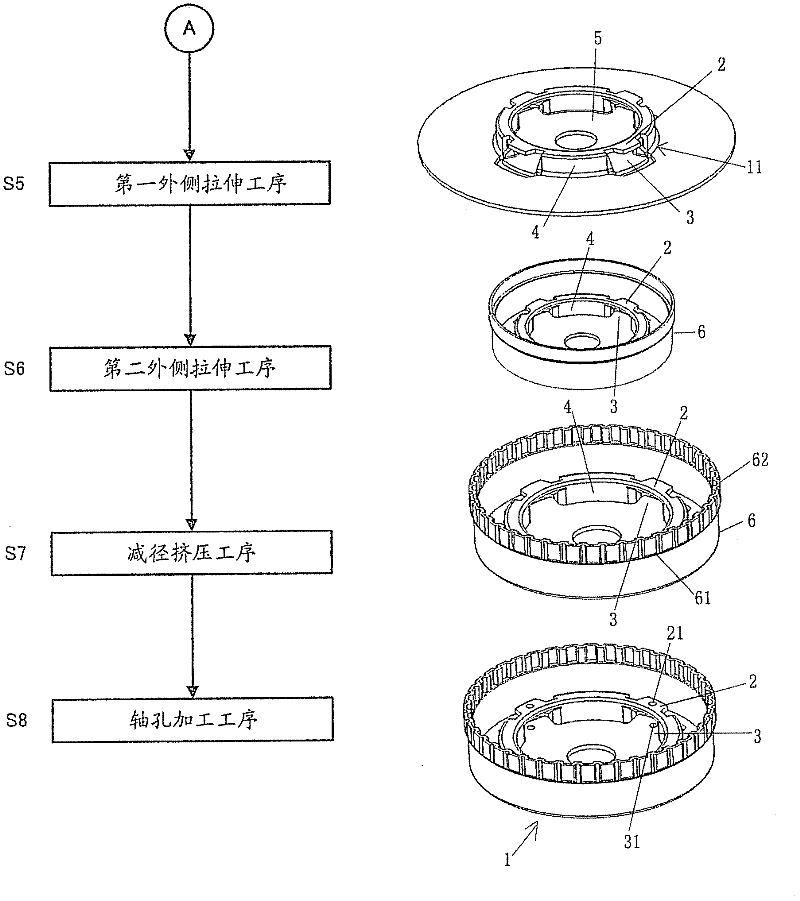

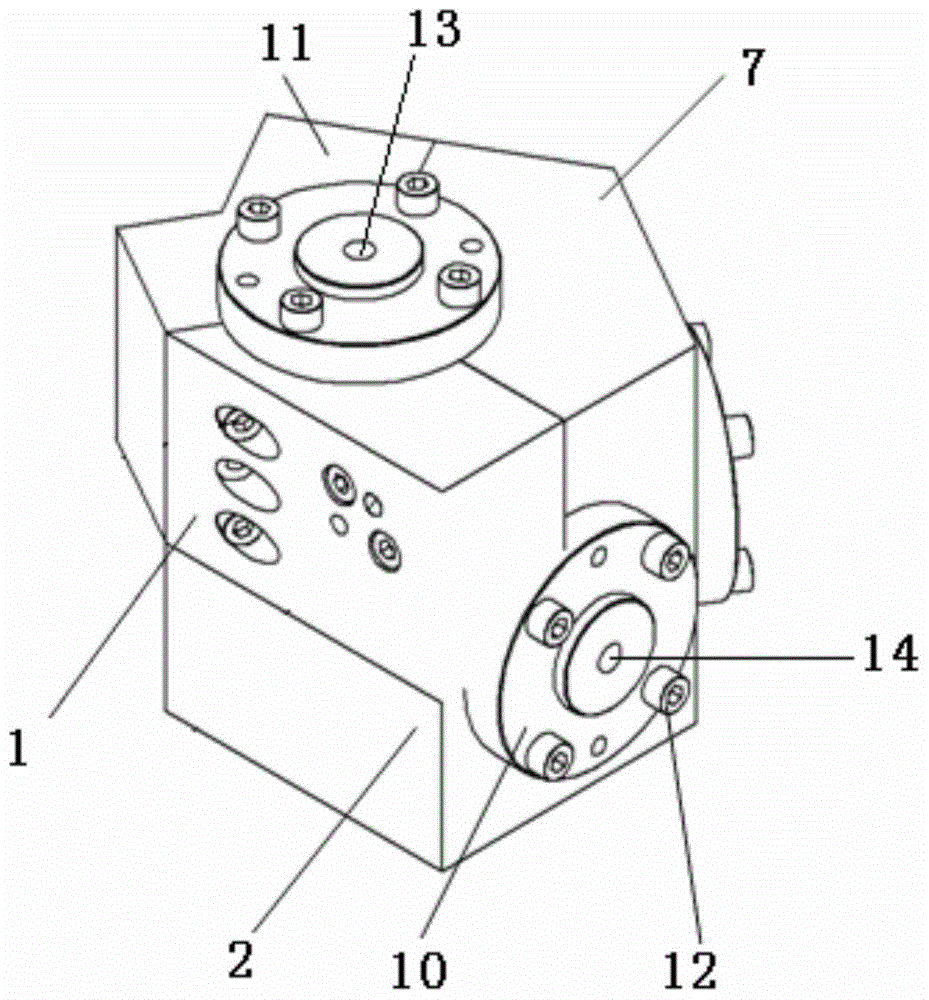

Gear support and method of manufacturing the same

InactiveCN102466030AReduce in quantityReduced processing performanceGearing detailsEngineeringUltimate tensile strength

Provided are a gear support and a method of manufacturing the same. The number of parts and the procedures for manufacturing the gear support are minimized, and the decreasing strength, caused by poor bonding, is minimized. A plurality of lower side support surface predetermined portions are arranged on the periphery of the gear support. The axial outer side of each lower side support surface predetermined portion is respectively provided with an upper side support surface predetermined portion. Blank material of wall predetermined portions are disposed among the adjacent lower side support surface predetermined portions so that the lower side support surface predetermined portions are bent inwardly in a radial manner. An opening, which is opened on the inner side, is arranged between the lower side support surface predetermined portions and the upper side support surface predetermined portions. The opening allows a planet gear to be exposed from the inner side of the gear support, allows the radial inner region of the blank material including the lower side support surface predetermined portions and the wall predetermined portions to be stretched, and makes the lower side support surface predetermined portions correspondingly move toward the upper side support surface predetermined portions. Therefore, an upper support surface, a lower support surface and a wall portion are formed, wherein the upper support surface and the lower support surface are parallel and are used for supporting the planet gear, and the wall portion axially extends along the gear support.

Owner:JATCO LTD

Method for forming composite material joints by using multi-directional composite material joint rtm mold

ActiveCN104260373BGuaranteed continuityGuaranteed mechanical propertiesChemical reactionCarbon fibers

Owner:BEIJING SATELLITE MFG FACTORY

Formaldehyde removing agent

InactiveCN1686596ANo loss of strengthPlay a closed roleDispersed particle separationWood working apparatusHazardous substancePolyvinyl alcohol

A form-aldehyde removing agent is proportionally prepared from water, 2-amino-2-ethyl-1-3-propanediol, Na2S2O3, Na2So3, pvA-1788, water-soluble edible essence, photocatalyst and assistant.

Owner:苏州市丛岭胶粘剂有限公司

Polycrystalline diamond element

InactiveCN102395694AWon't meltReduce penetration rateConstructionsAbrasion apparatusMetallic materialsPolycrystalline diamond

An embodiment of a PCD insert comprises an embodiment of a PCD element joined to a cemented carbide substrate at an interface. The PCD element has internal diamond surfaces defining interstices between them. The PCD element further comprises a working surface and a low melting point region adjacent the working surface in which the interstices are at least partially filled with a low melting point metallic material having a melting point of less than about 1,300 degrees centigrade at atmospheric pressure, or less than about 1,200 degrees centigrade at atmospheric pressure. The PCD element includes an intermediate region, the interstices of the intermediate region being at least partially filled with a catalyst material for diamond.

Owner:ELEMENT SIX PRODION

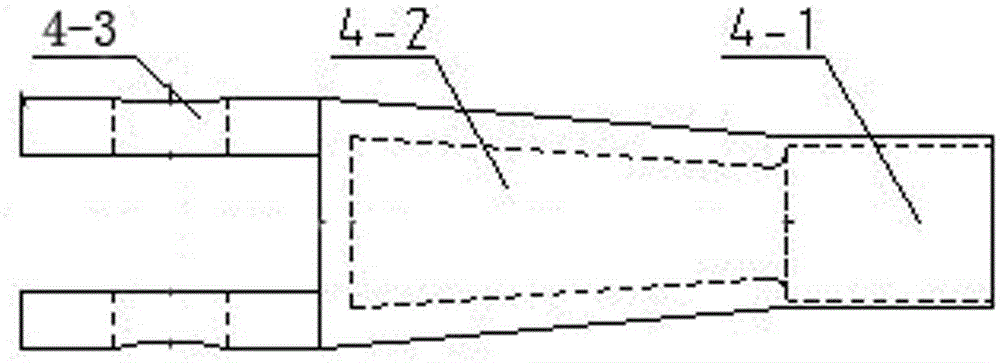

Plug-in steel wire rope connector and manufacturing method thereof

ActiveCN105156588ANo loss of strengthRopes and cables for vehicles/pulleyTextile cablesWeld seamFiller metal

The invention relates to a plug-in steel wire rope connector which comprises a casting body and a steel wire rope. The end of the steel wire rope is inserted into an opening of the casting body and welded together. The casting body is a closed type casting body with an opening formed in the end. An inner cavity of the opening end of the casting body is divided into an inverted-cone cavity body and a filling shrinkage cavity body. The inverted-cone cavity body is a cone opening gradually shrunk from inside to outside. The filling shrinkage cavity body is formed in the outer end of the inverted-cone cavity body. The inner diameter of the filling shrinkage cavity body is larger than the inner diameter of the inverted-cone cavity body at the transition portion of the filling shrinkage cavity body and the inverted-cone cavity body. According to the plug-in steel wire rope connector, as the casting body is arranged in a closed form with one end open, the filling shrinkage cavity body is designed in the end, before the end of the steel wire rope is inserted into the casting body, brazing filler metal is placed into the casting body, and the brazing filler metal in the filling shrinkage cavity body is shrunk due to the fact that liquid brazing filler metal in the inverted-cone cavity body is cooled and turned into a solid, so that most brazing filler metal flows into the inverted-cone cavity body, and a welding seam structure basically flawless in the inverted-cone cavity body is formed.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

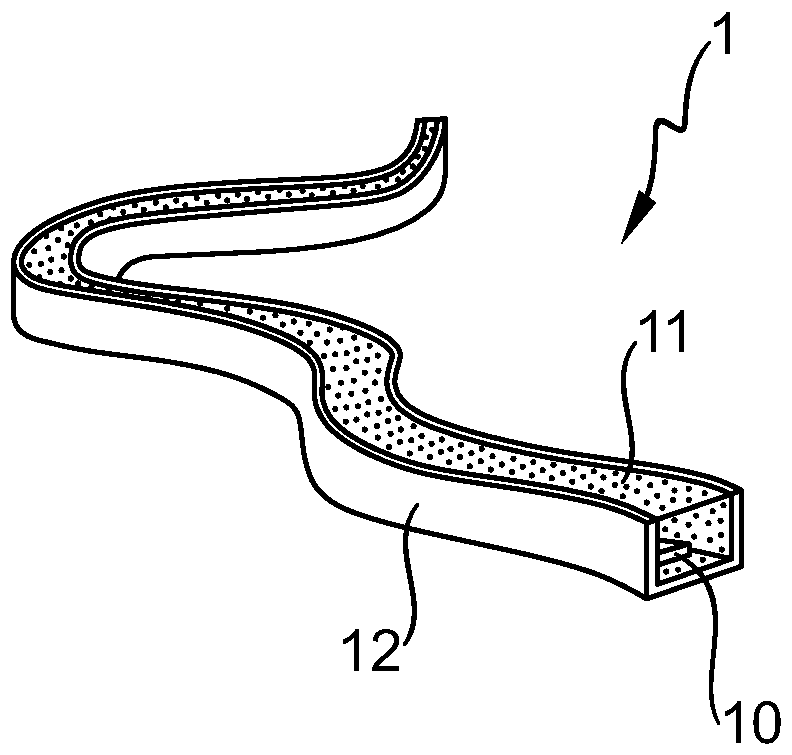

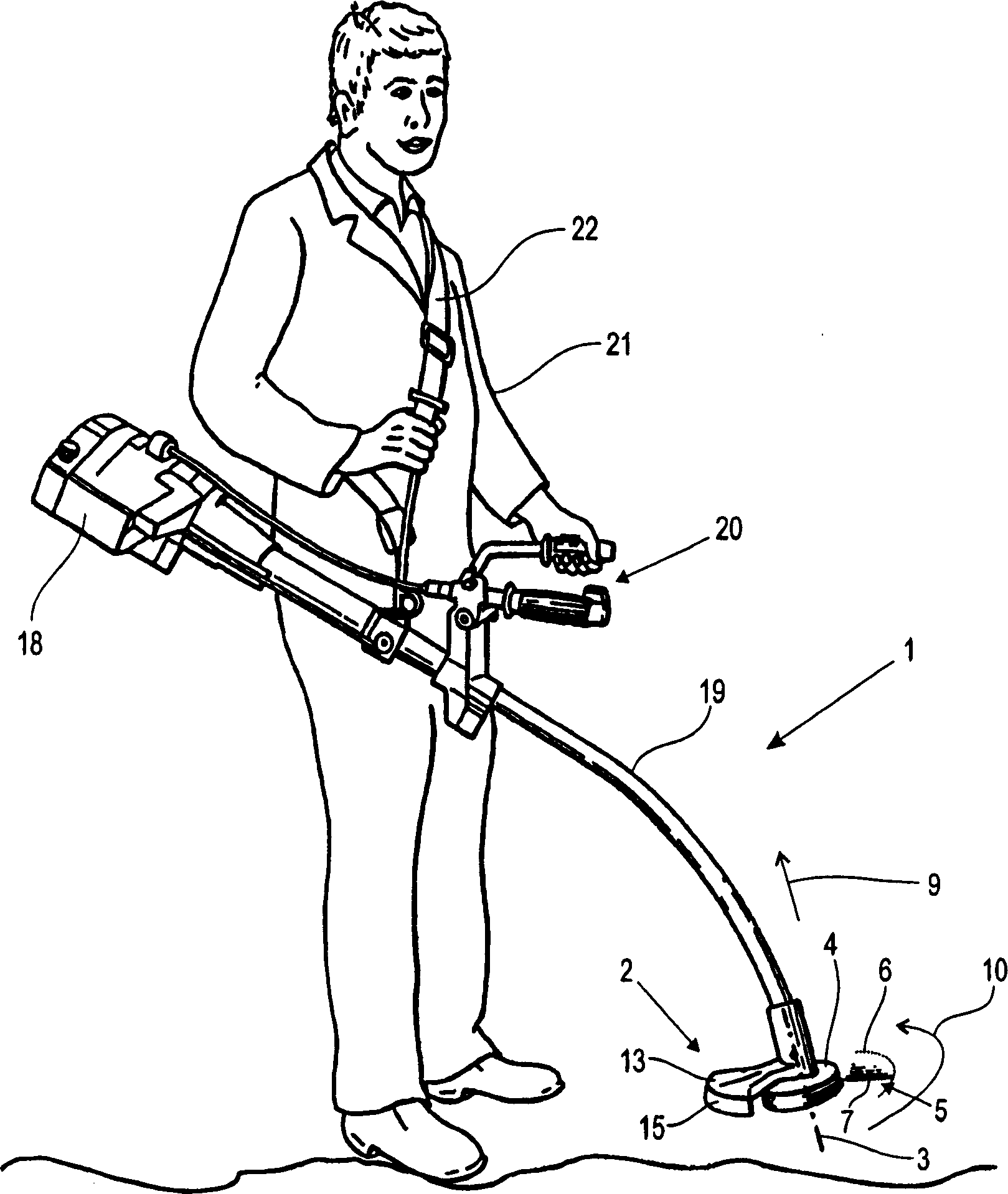

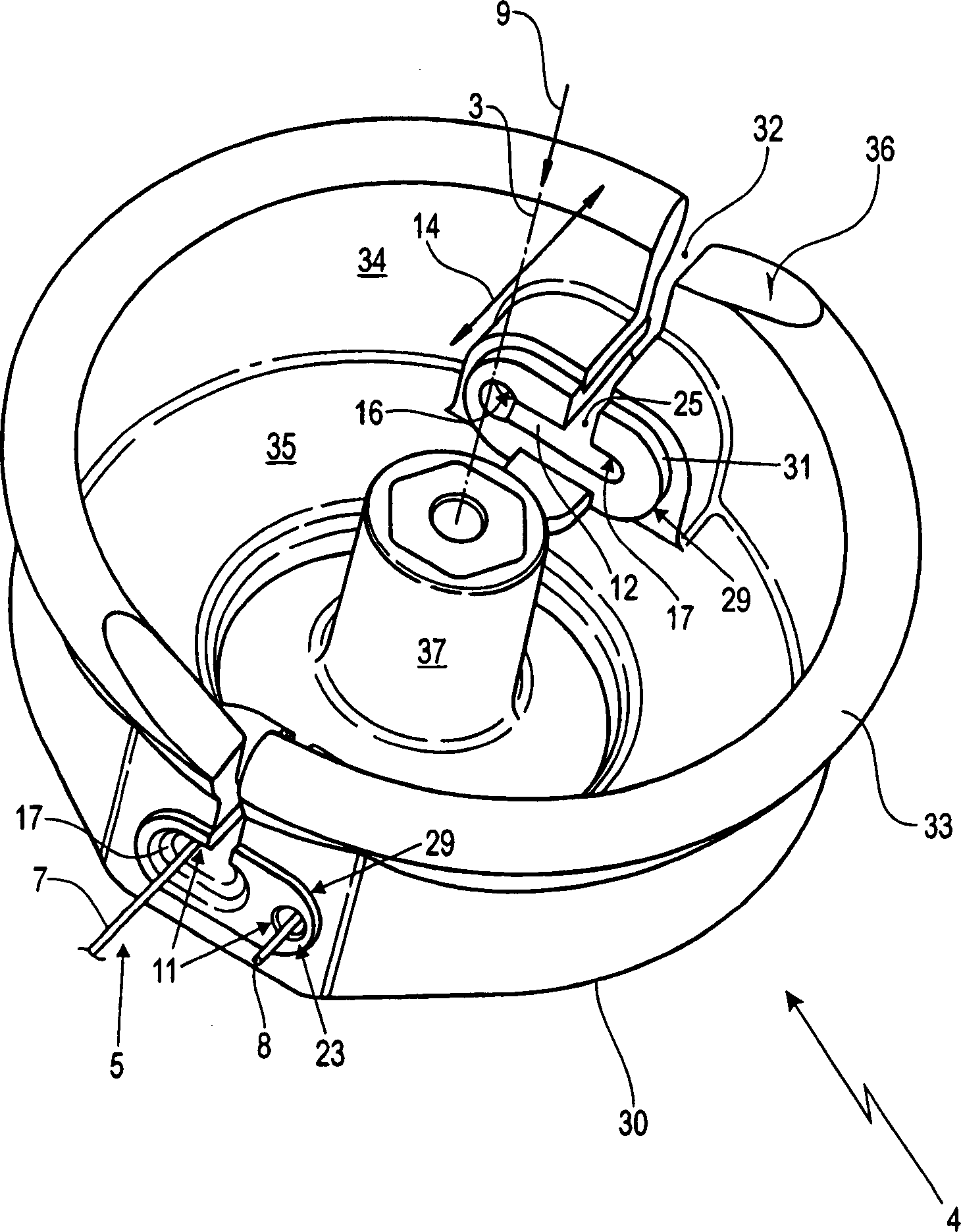

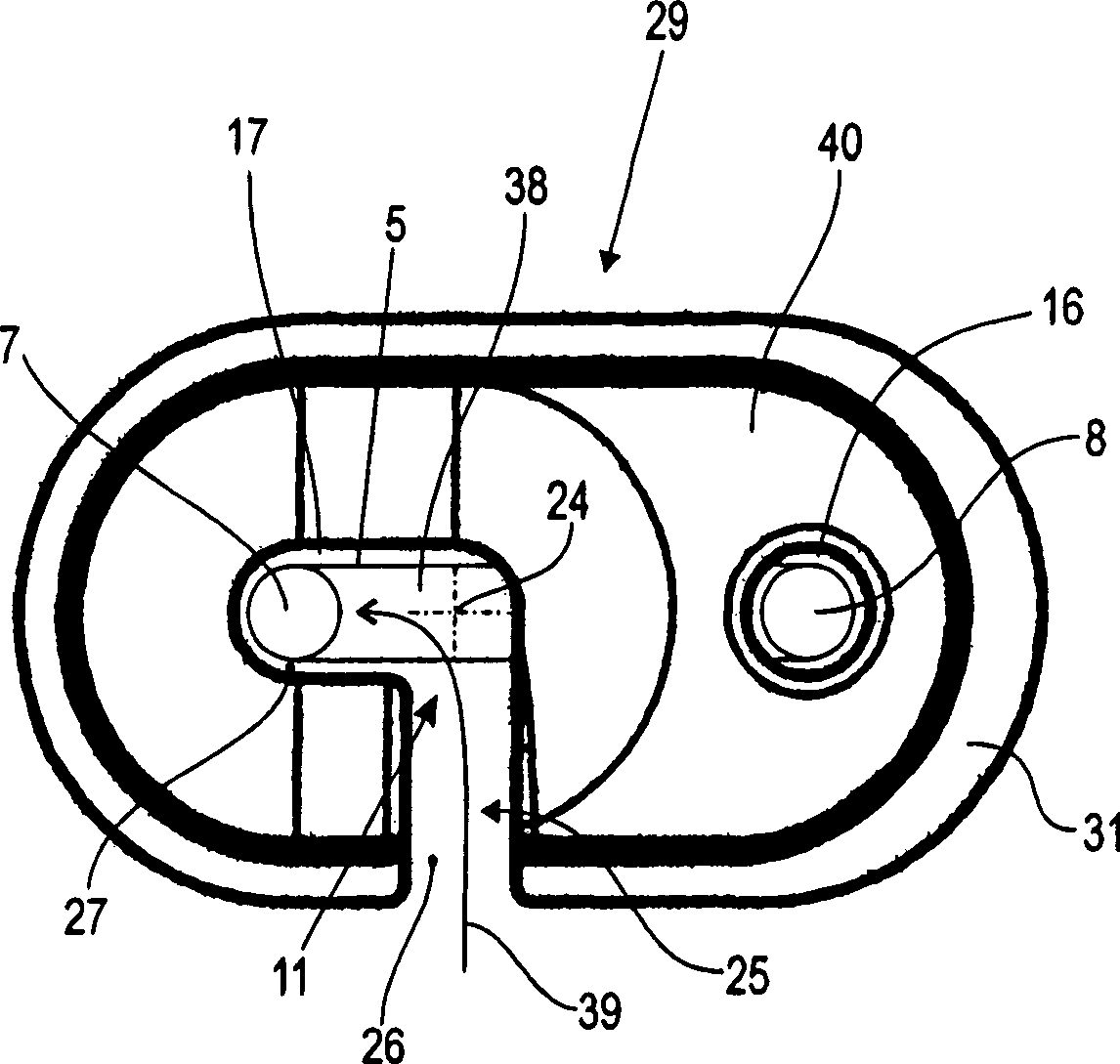

Cutter head for a trimmer

The invention relates to a cutting head (4) of a cleaning cutter (1), which is driven in rotation about an axis of rotation (3) and carries at least one cutting wire (5). The cutting wire (5) has a radially outer cutting zone (7) with respect to the axis of rotation (3) and is fixed on the cutting head ( 4) on. In order to fix the clamping end (8), a roughly U-shaped receiving groove (11) is provided on the cutter head (4). The clamping end (8) of the cutting wire (5) passes through the first side leg (16) of the U-shaped receiving groove (11), while the cutting zone (7) passes through the second side leg of the U-shaped receiving groove (11) (17). The receiving groove (11) between the two side legs (16, 17) is a clamping zone (38) for the cutting wire (5) with a wedge-shaped clamping tapered in the direction of the clamping end (8). Paragraph (12).

Owner:ANDREAS STIHL AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com