Composite material construction for high-speed train and its manufacturing method

A technology for composite materials and high-speed trains, applied in superstructures, subassemblies of superstructures, chemical instruments and methods, etc., can solve the problems of non-planar panel surfaces and fatigue damage of aluminum alloy sheets, and achieve reduced life cycle costs and high Effects of impact damage tolerance and high fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 The floor cover in the lower structure of the front of the car

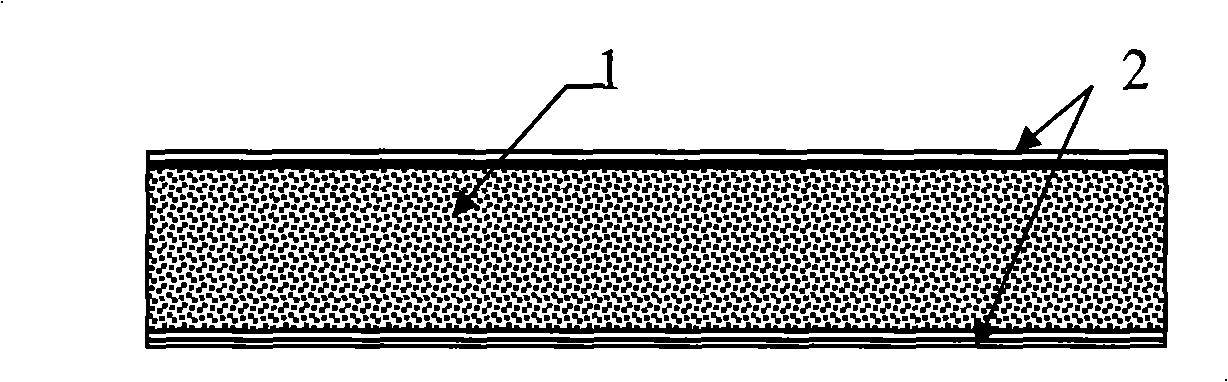

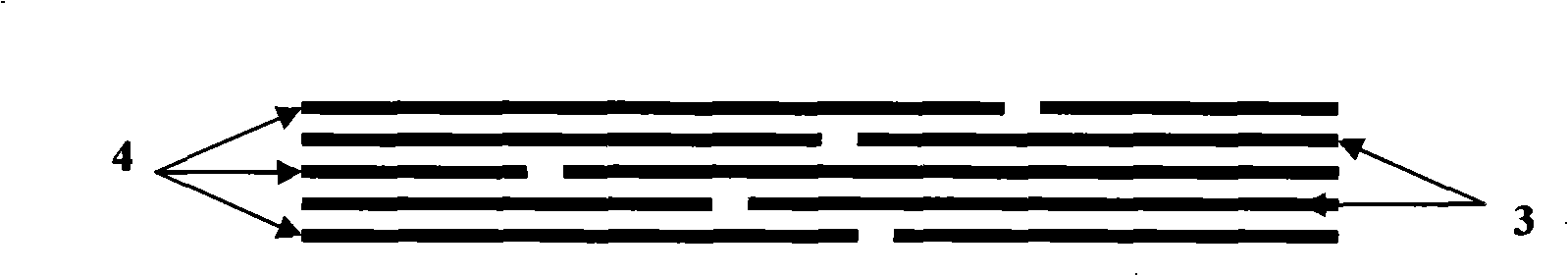

[0038] These floor covers were manufactured with the fiber reinforced aluminum panel foam sandwich of the present invention. A 3 / 2 laminated glass fiber reinforced aluminum alloy laminate panel 2 is used as the upper panel, and the panel contains three layers of aluminum alloy sheets 4 each 0.3 mm thick and two layers of high-strength glass fiber reinforced epoxy resin each 0.2 mm thick ( GFRP) laminate 3 with a total thickness of 1.3mm; 4 / 3 layered glass fiber reinforced aluminum alloy laminate panel 2 is the lower panel, which contains four layers of aluminum alloy sheets 4 each 0.3mm thick and three layers each 0.2 mm thick high-strength glass fiber reinforced epoxy resin (GFRP) laminate 3 with a total thickness of 2 mm. In this way, products that meet the structural performance requirements and have better impact resistance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com