Composite material for high-speed train and its manufacturing method

A composite material, high-speed train technology, applied in the superstructure, superstructure sub-assemblies, chemical instruments and methods, etc., can solve the problems of fatigue failure of aluminum alloy sheets, the surface of the panel is not flat, etc., to achieve high impact damage tolerance, The effect of reducing life cycle costs, improving fatigue and impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

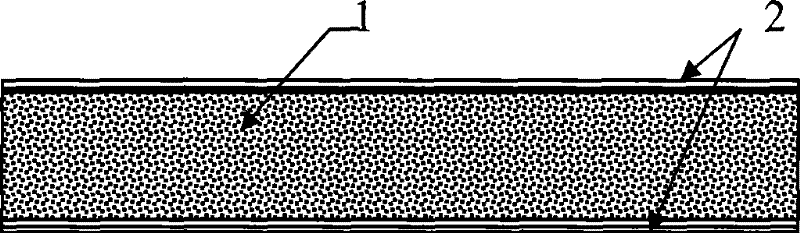

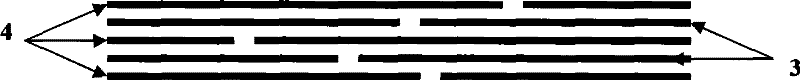

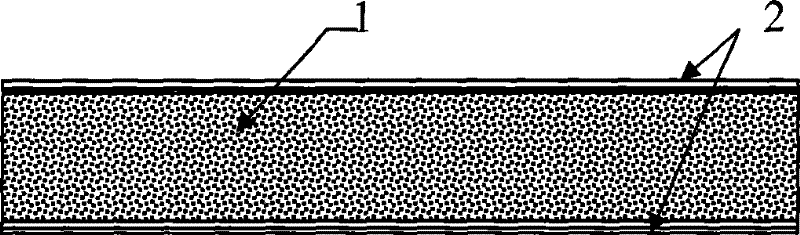

[0037] Embodiment 1 The floor cover in the lower structure of the front of the car

[0038] These floor covers were manufactured with the fiber reinforced aluminum panel foam sandwich of the present invention. A 3 / 2-layer glass fiber reinforced aluminum alloy laminate panel 2 is used as the upper panel, and the panel contains three layers of aluminum alloy sheets 4 each 0.3 mm thick and two layers of high-strength glass fiber reinforced epoxy resin each 0.2 mm thick ( GFRP) laminate 3 with a total thickness of 1.3mm; 4 / 3 layered glass fiber reinforced aluminum alloy laminate panel 2 is the lower panel, which contains four layers of aluminum alloy sheets 4 each 0.3mm thick and three layers each 0.2 mm thick high-strength glass fiber reinforced epoxy resin (GFRP) laminate 3 with a total thickness of 2 mm. In this way, products that meet the structural performance requirements and have better impact resistance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com