Polycrystalline diamond element

A polycrystalline diamond and diamond technology, applied in metal processing equipment, construction, abrasives, etc., can solve problems such as poor thermal stability, and achieve the effect of improving thermal stability without compromising strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

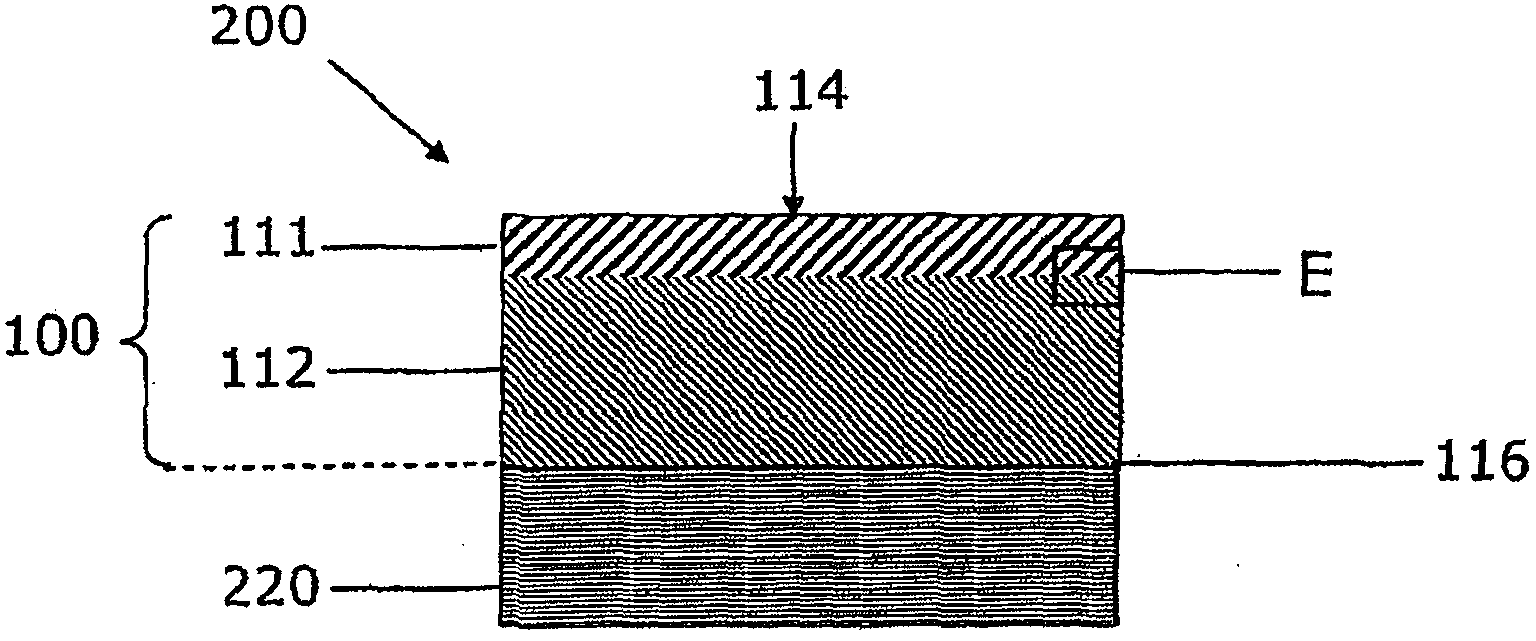

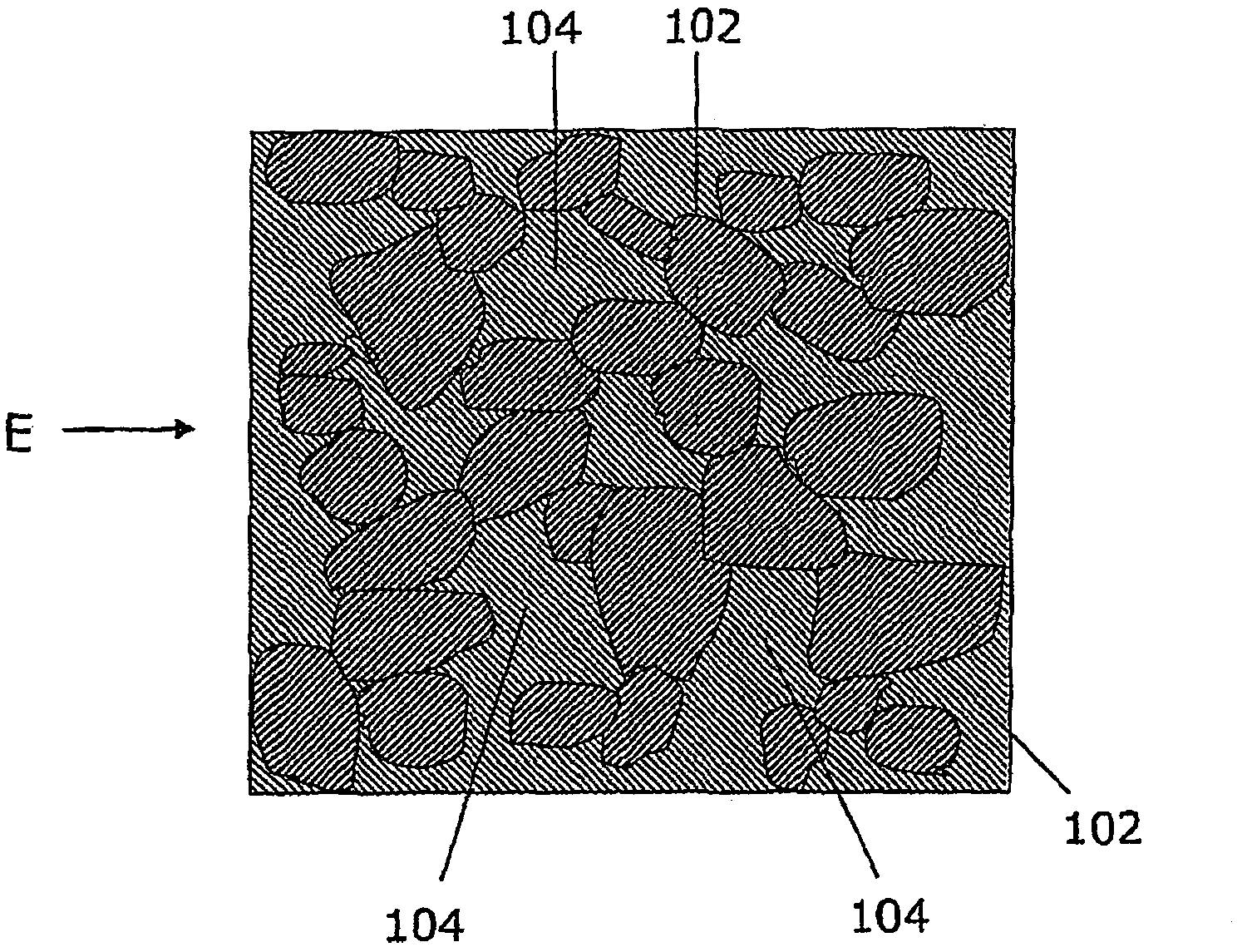

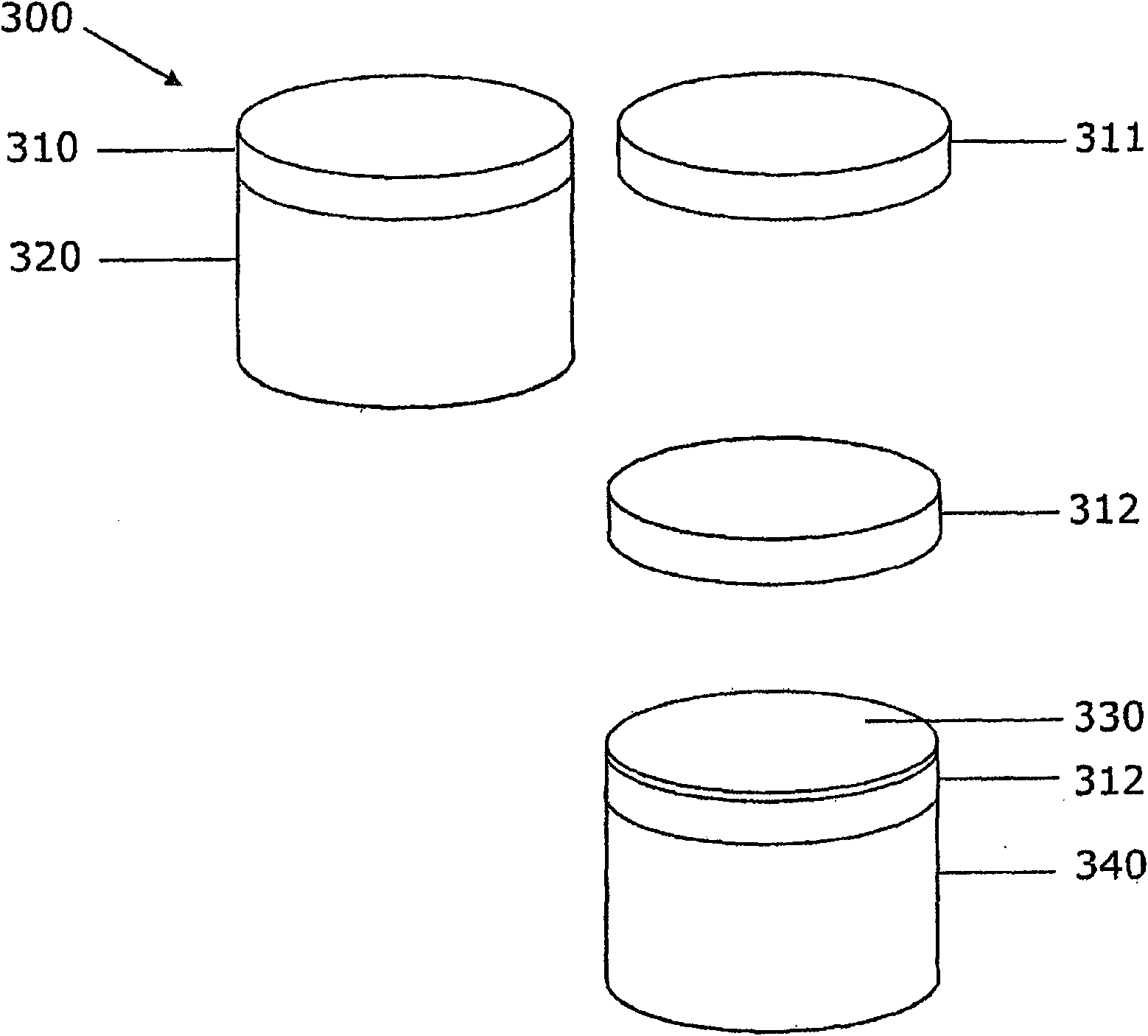

[0058] A PCD insert with a diameter of approximately 16 mm and used for rotary drag bits for oil and gas drilling was used as a starting element. The insert is substantially cylindrical and comprises a PCD layer integrally bonded to the WC hard metal substrate of the Co junction. The PCD layer is about 2.3 millimeters thick, and the diamond grain size distribution is of the multimodal type, comprising sintered diamond grains with an average grain size of less than about 20 microns, the interstices between the diamond grains being filled with Co (during the step of sintering the PCD Catalyst metal) filling from the hard metal substrate during the process. Substantially all of the hard metal substrate is machined away from the PCD layer to provide a PCD flake. Porous, isolated PCD pellets were subsequently removed by immersing them in a mixture of hydrofluoric and nitric acids for several days to remove substantially all of the Co from the PCD pellets. The PCD pellets are heat...

Embodiment 2

[0064] The repermeation insert was fabricated using the same method as in Example 1, the only difference being that silver foil was used instead of copper foil. The insert was also analyzed and tested as in Example 1.

[0065] Silver penetrated deeper into the PCD than copper, to a depth of about 2.2 mm from the flat work surface. This is thought to be due to the lower melting point of silver and the fact that it melts at an earlier stage than copper and therefore has more time to infiltrate the porous PCD before the cobalt melts and infiltrates from the opposite direction.

Embodiment 3

[0067] Porous PCD pellets can be prepared using the method described in Example 2, and silver can be introduced into the pores prior to treatment at ultrahigh pressure. This can be achieved by placing the porous PCD pellet into a graphite container and disposing on it a silver film that has been ultrasonically cleaned in an acetone bath. The container can then be placed in a furnace and its contents heated in vacuum to above the melting point of silver, ie about 1,000°C, causing the silver foil to melt and infiltrate the PCD sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com