Cutter head for a trimmer

A technology of cutters and cutter heads, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

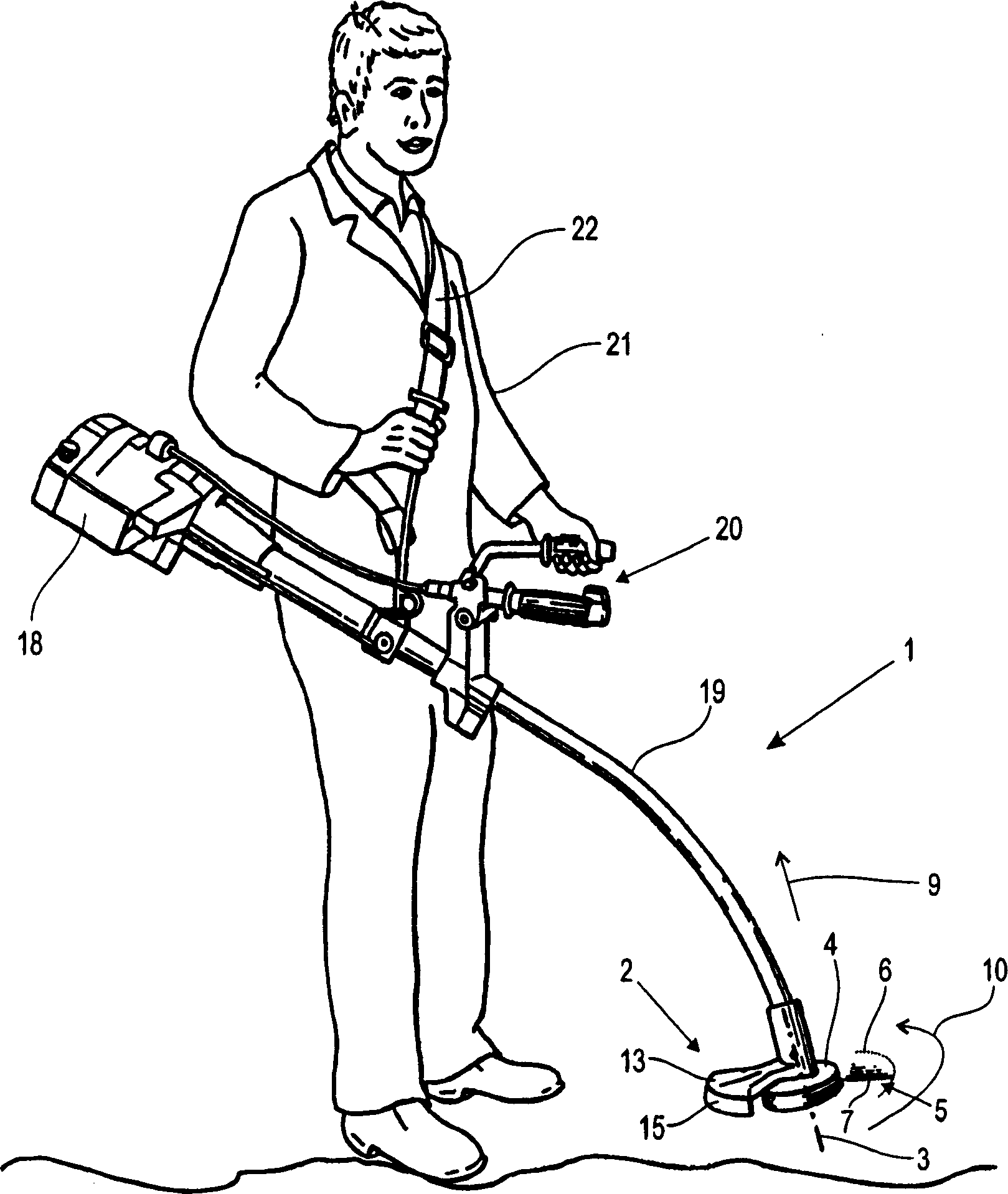

[0022] figure 1 Represent an operator 21 with a shoulder strap 22 to suspend a removal cutter 1 in a general working posture or an appearance diagram of an operating posture. The debriding cutter 1 comprises a conduit 19, at one end of which a motor unit 18 is arranged and at its opposite end a cutting head 4 is arranged. Inside the guide tube 19 there is a drive shaft, not shown, by means of which a drive motor, also not shown, drives the cutting head 4 in rotation. For actuating the clearing cutter 1 , a handle unit 20 is provided on the catheter 19 , on which the operating elements for controlling the drive motor are arranged.

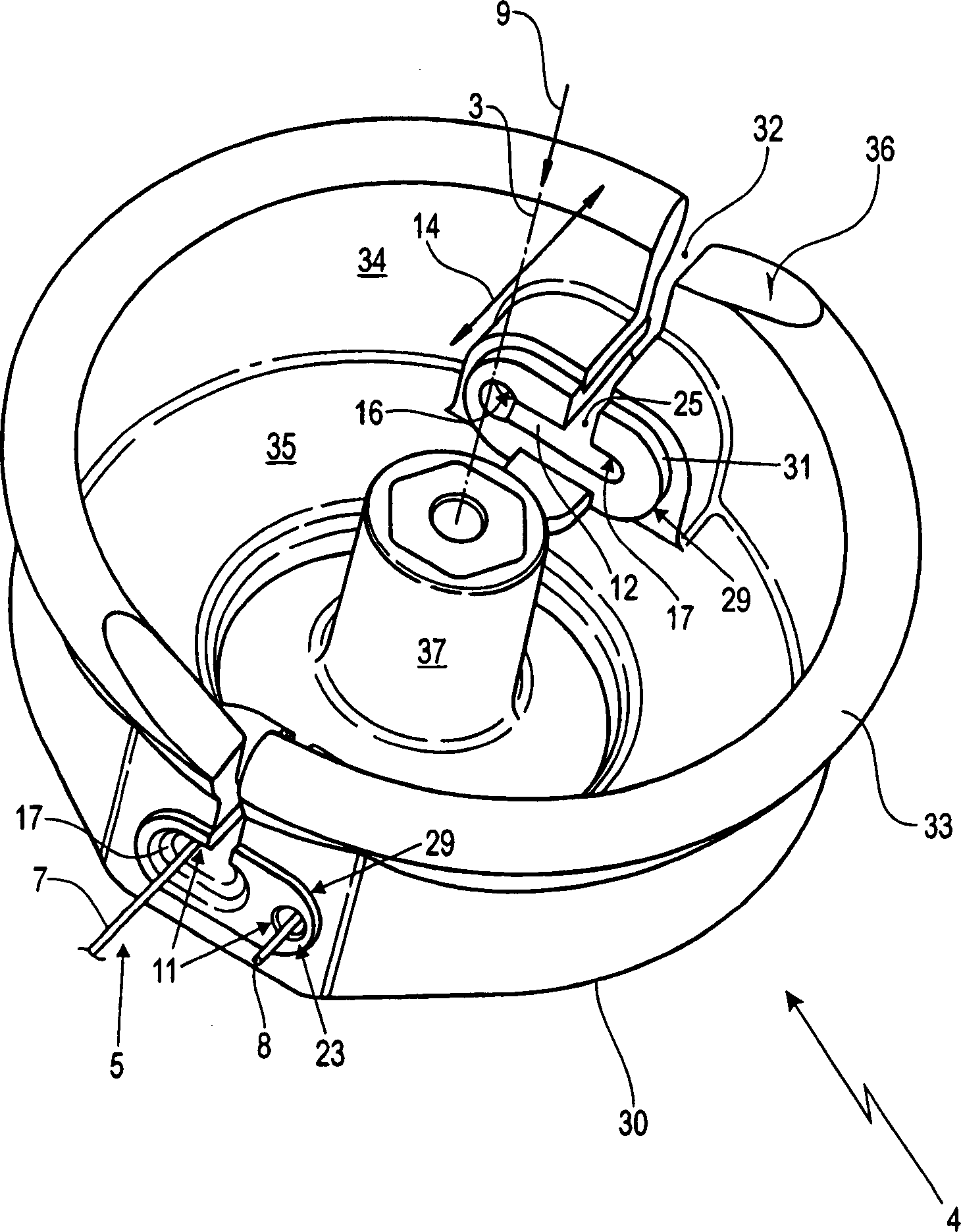

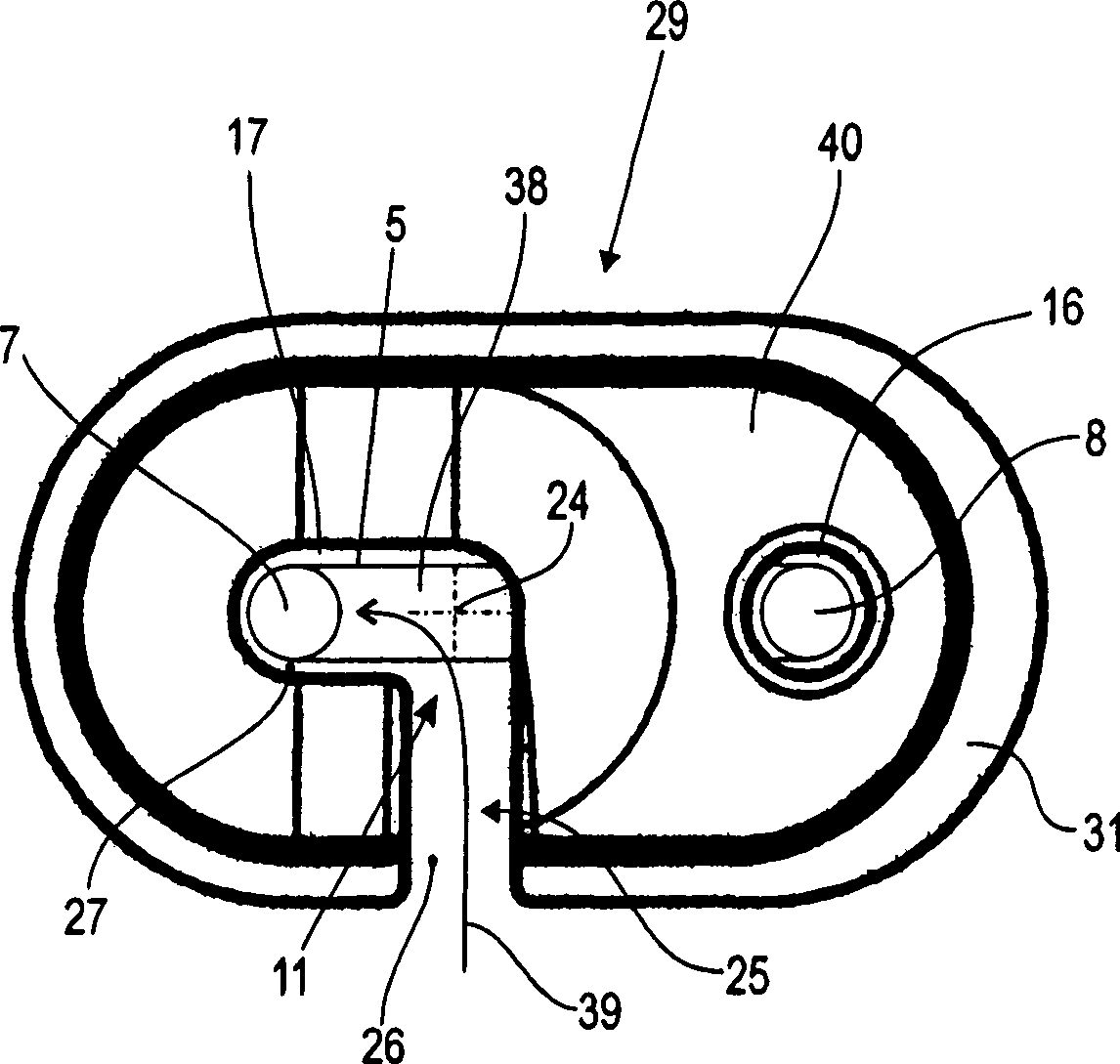

[0023] The cutter head 4 carries a cutting wire 5 which, during operation, rotates together with the cutter head 4 about a rotational axis 3 in the direction of rotation indicated by the arrow 10 . The flexible cutting wire 5 made of plastic is aligned approximately radially with the axis of rotation 3 due to the centrifugal force generated during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com