A plug-in wire rope joint and its manufacturing method

A wire rope, plug-in technology, used in the direction of rope or cable for transmission elements or pulleys, textile cables, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

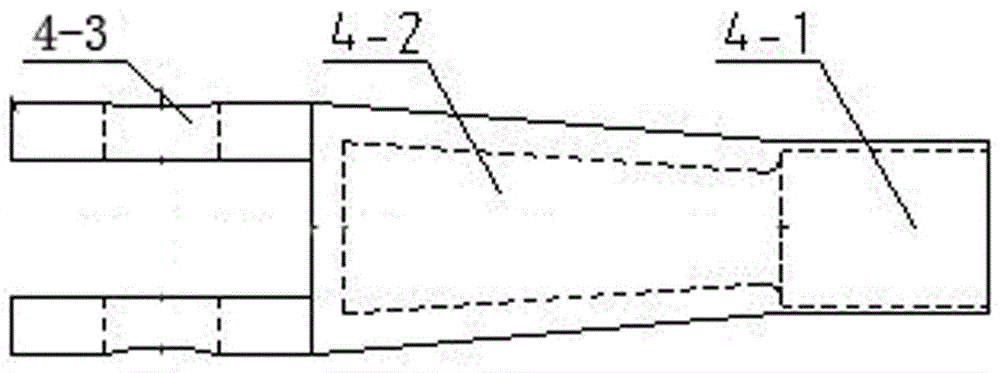

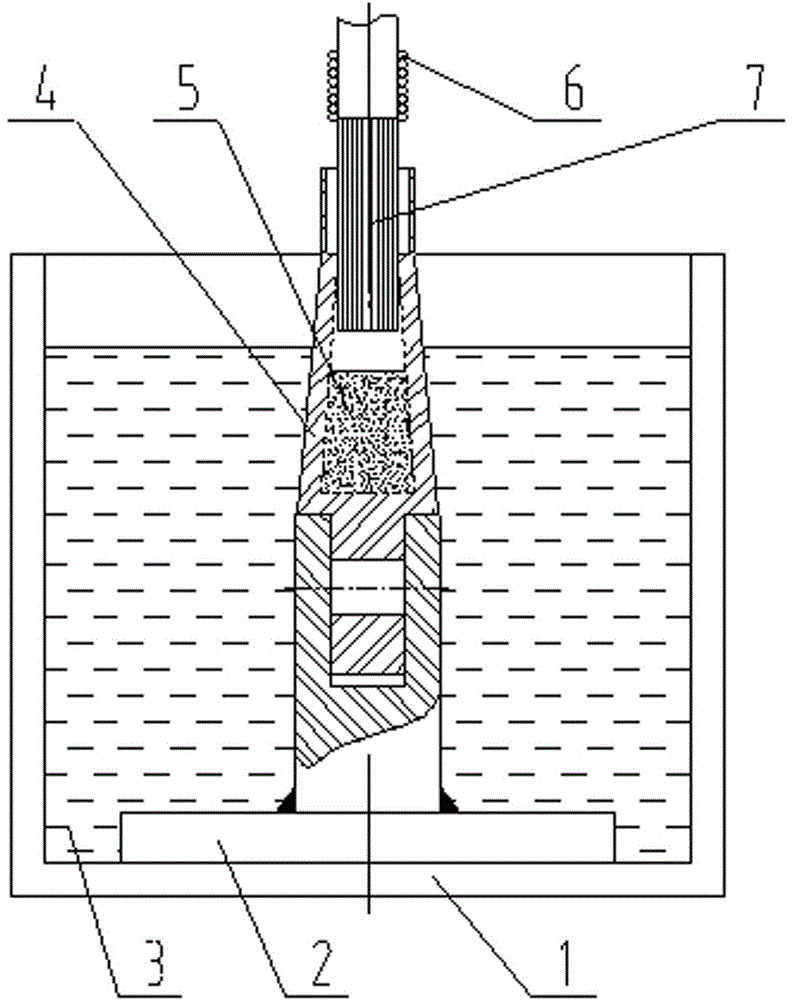

[0020] Referring to the accompanying drawings, a plug-in wire rope joint includes a casting body 4 and a steel wire rope 7. The ends of the steel wire rope 7 are inserted into the opening of the casting body 4 and welded together. The casting body 4 is a closed type with an open end. Casting body, the inner cavity of the opening end of the pouring body 4 is divided into an inverted cone cavity 4-2 and a feeding cavity 4-1, the inverted cone cavity 4-2 is a tapered mouth that gradually shrinks from the inside to the outside, and the feeding cavity The shrinking chamber 4-1 is arranged at the outer end of the inverted cone chamber 4-2, and the inner diameter of the feeding chamber 4-1 at the transition between the feeding chamber 4-1 and the inverted cone chamber 4-2 is larger than that of the inverted cone chamber 4-2 The inner diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com