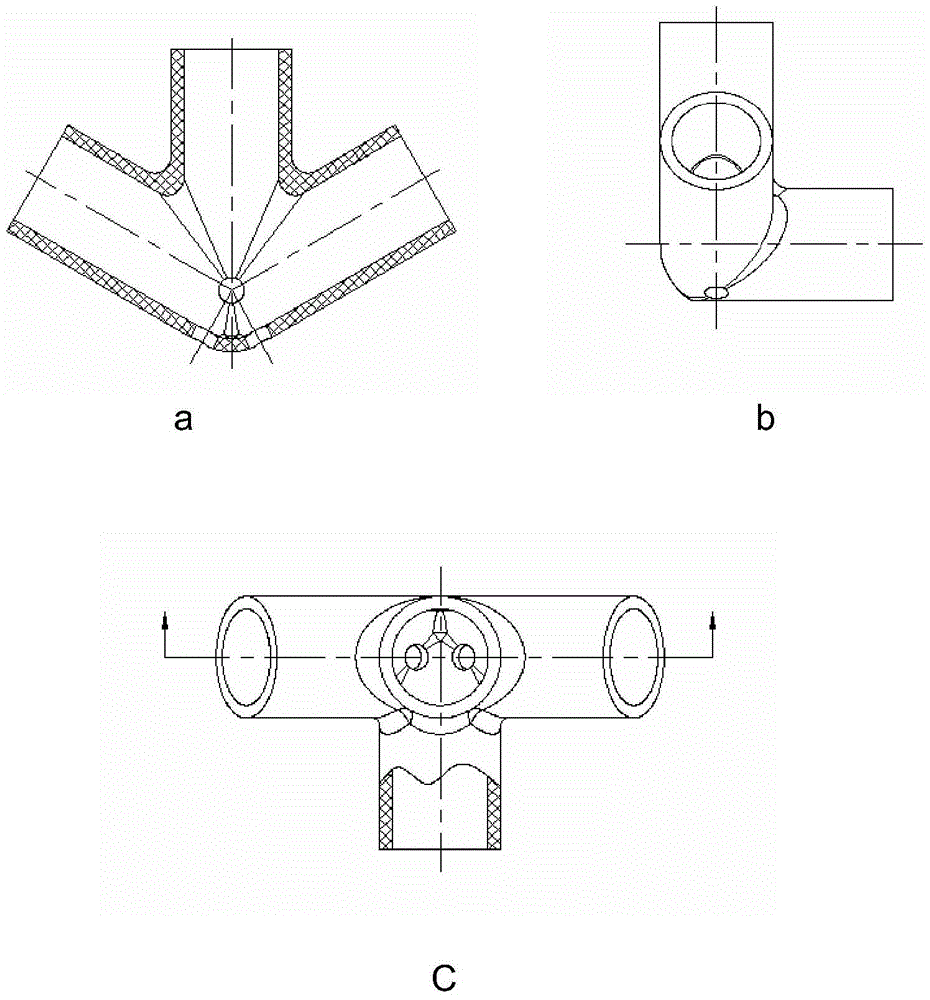

Method for forming composite material joints by using multi-directional composite material joint rtm mold

A composite material and mold forming technology, which is applied in the field of carbon fiber reinforced resin-based composite material structure forming, to avoid fiber bundle breakage, ensure forming accuracy, and solve the effects of tolerance design and positioning design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

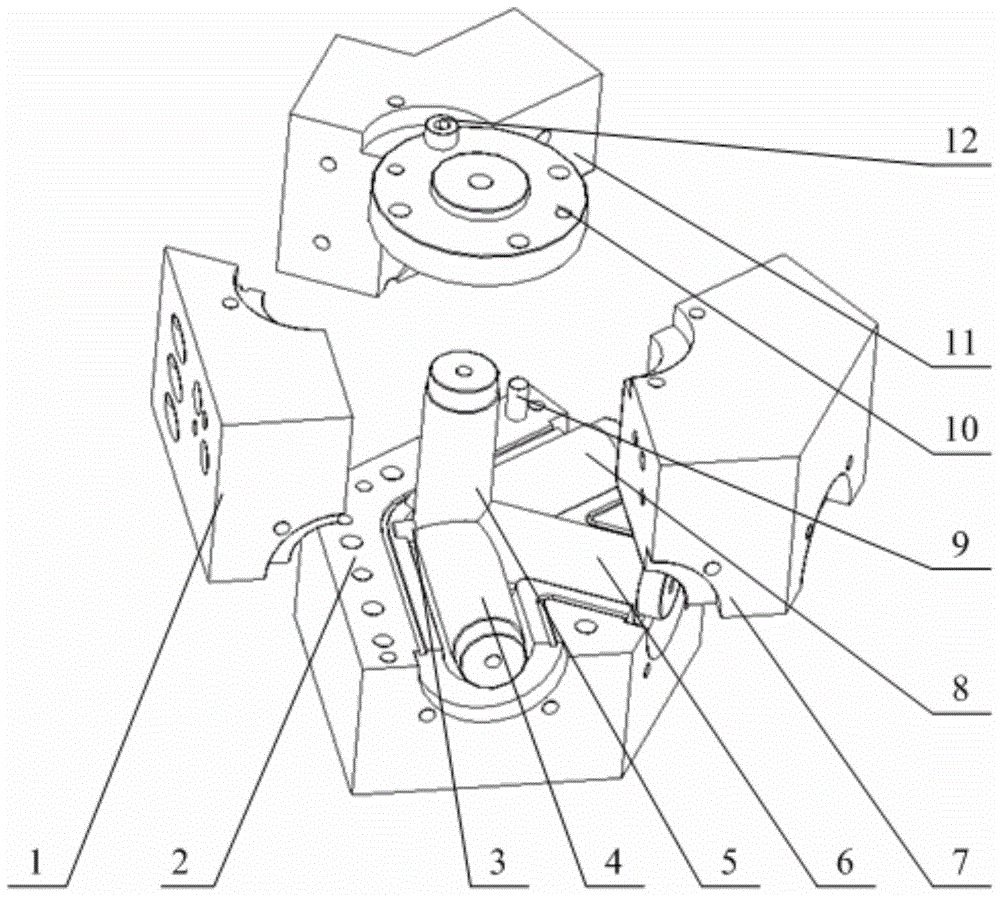

Method used

Image

Examples

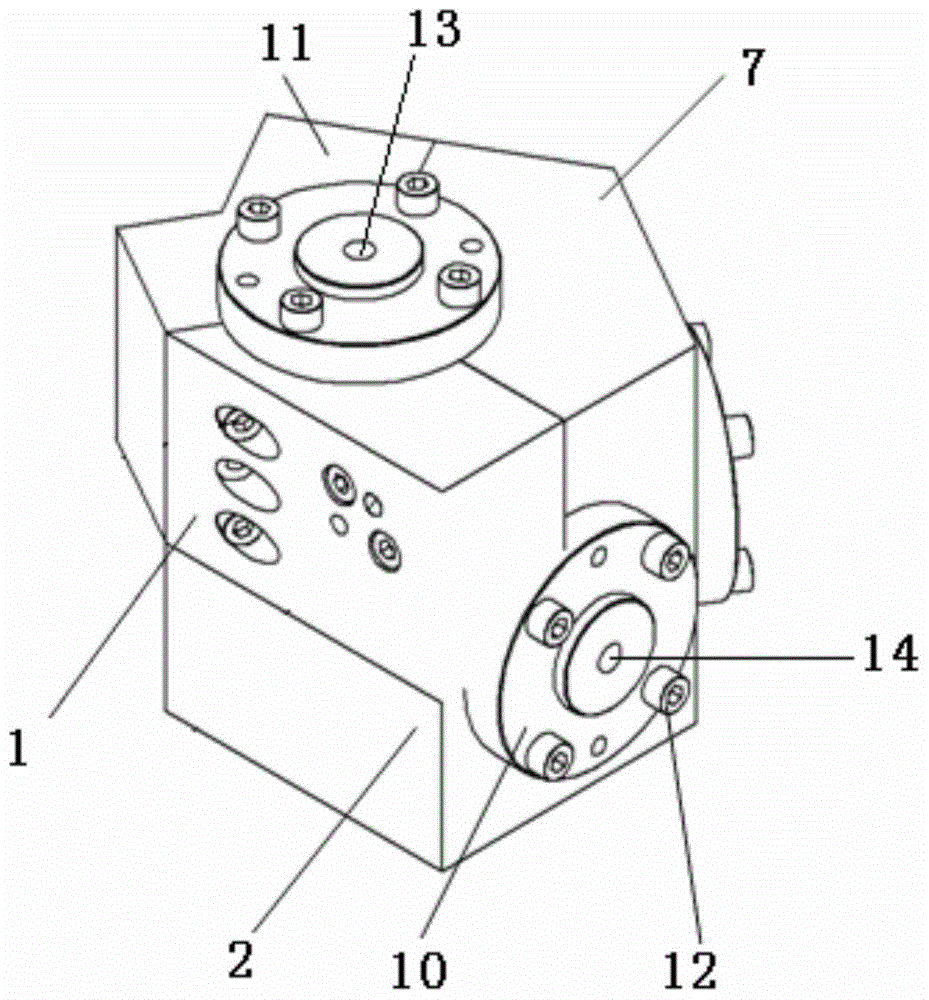

Embodiment 1

[0049] The four-way composite material joint RTM forming mold has an external dimension of 230×180×170, the outer diameter of the formed joint is 38mm, the inner diameter is 30mm, the diameter of the embedded part installation hole is Ф8, and the composite material is high modulus fiber / epoxy resin. The prefabricated hole mandrel is a cylindrical solid structure, its external dimension (diameter) tolerance is (0,+0.1), the prefabricated hole mandrel positioning hole (diameter) tolerance on the mold is (-0.1,0), and the length of the positioning section is 10mm. The non-destructive testing of the four-way composite material joint formed by this mold meets the requirements of GJB2895-A level, the tolerance of the external dimension meets the requirements (+0.15~+0.25), and the measured value of the prefabricated hole diameter accuracy is Ф8.12mm, which meets the tolerance requirements (+0.1~ +0.2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com