Method for making slide sleeve ring

A technology for sliding sleeves and pressed products, applied in the field of sliding sleeve rings, can solve the problems of time-consuming and expensive processing of geometric structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

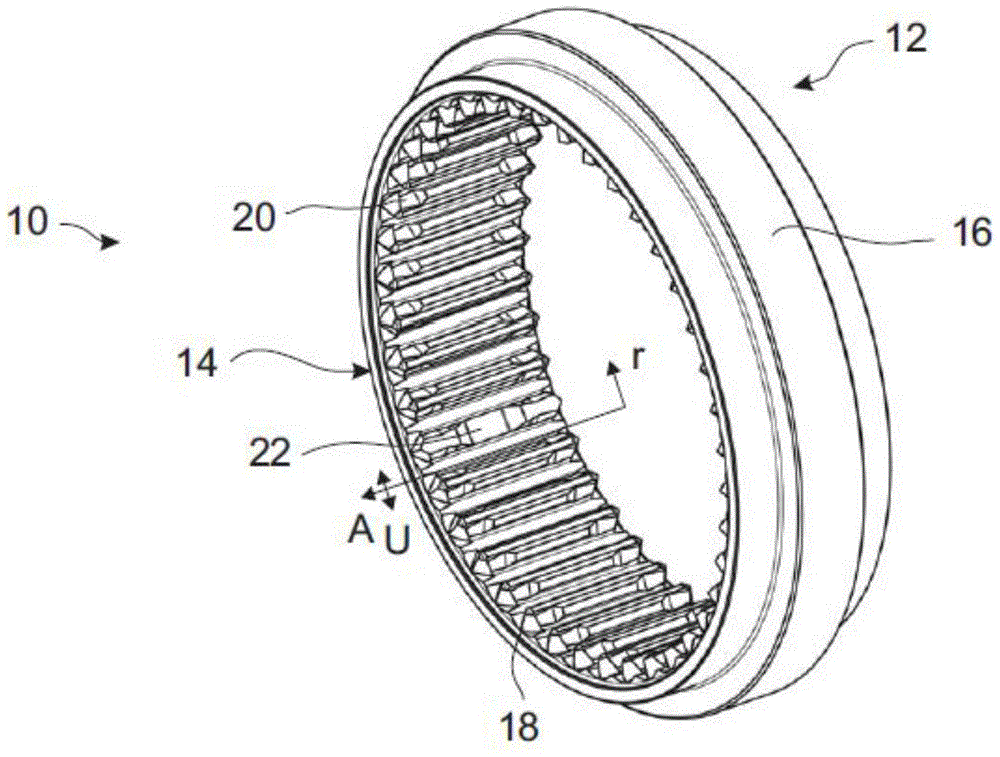

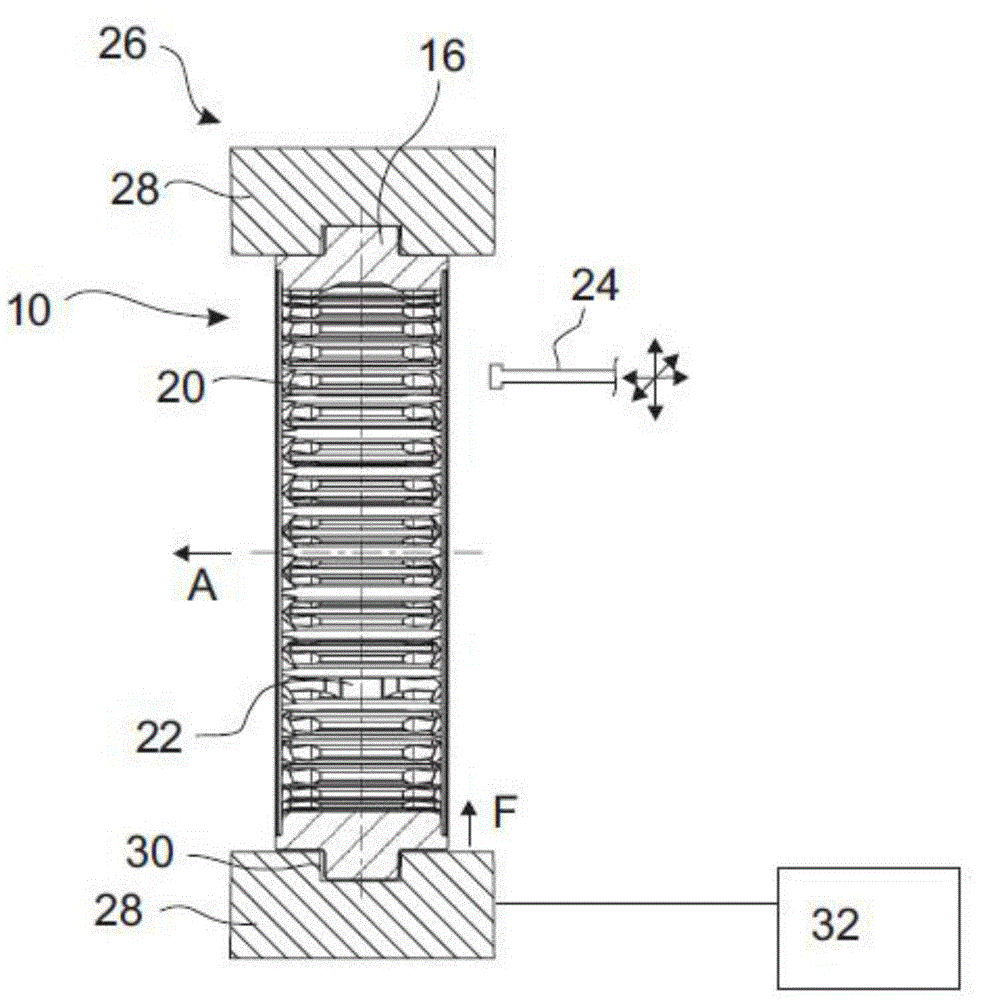

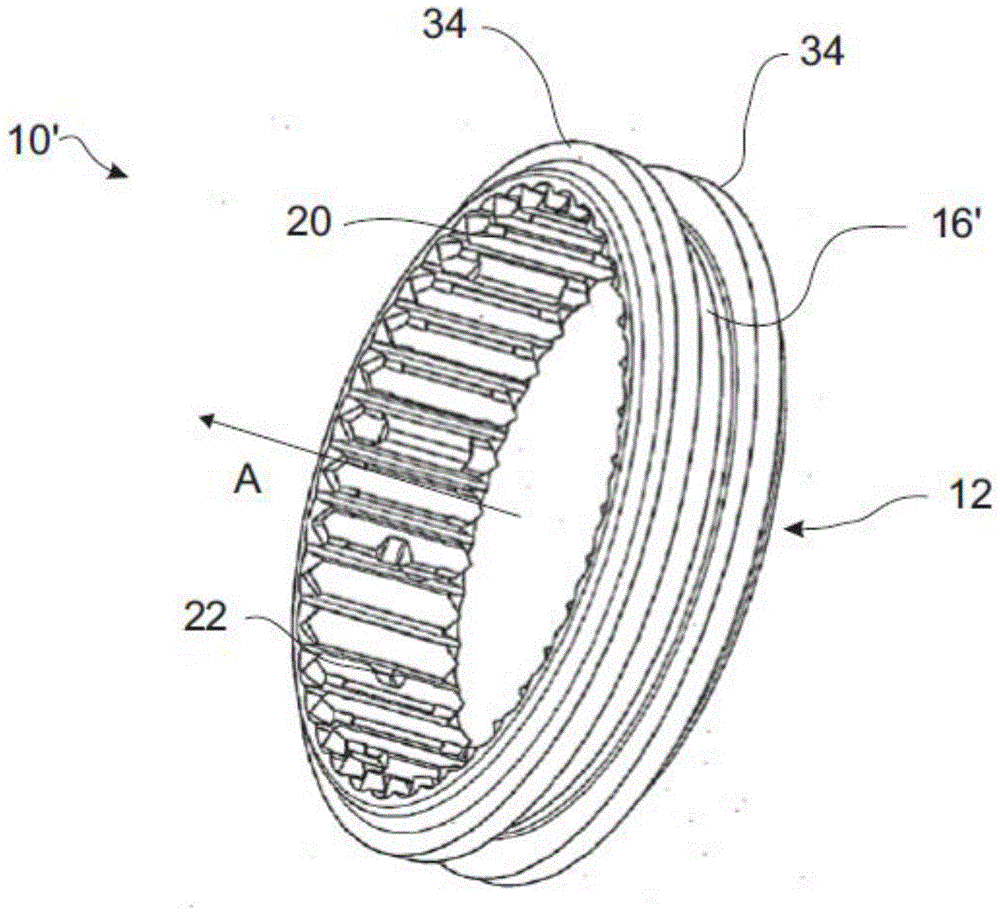

[0029] figure 1 The machined compact 10 of the sliding sleeve ring 12 of the sliding sleeve is shown. In the sintering method, the sliding sleeve ring of the finished sliding sleeve is formed from the sliding sleeve ring 12 substantially without changing its outer contour. Since the sintered sliding sleeve ring appears identical to the processed compact 10 , the finished sliding sleeve ring is not shown separately here.

[0030] To produce the pressed product 10 , first the powdered metal material is pressed under pressure in a tool (not shown). Suitable metals are eg ferrous materials. The powder used should be as random as possible, so that a sufficiently high blank strength can be achieved.

[0031] The pressed product 10 obtained in this way already has the basic shape of the finished sliding sleeve ring 12 . The inner toothing 14 for the selector fork on the radially outer peripheral side and the meshing geometry 16 in the form of an annular radially protruding shift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com