High-temperature-resistant AlN and Al2O3 co-reinforced aluminum-base composite material and method for preparing same

An aluminum-based composite material and high-temperature-resistant technology, applied in the field of metal-based composite materials, can solve the problems of melting, high cost, powder agglomeration, etc., and achieve the effect of increasing the surface alumina content, improving production efficiency, and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

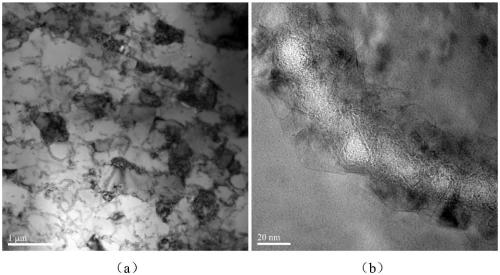

[0029] Select 10 kg of spherical aluminum powder with an average particle size of 2.5 microns, put it into a cylindrical steel mold with an inner diameter of 130 mm after cold isostatic pressing, and drill 15 round holes with a diameter of 1 mm at each end after sealing. Place in an air furnace at 400°C for 4 hours, then raise the temperature to 600°C for 5 hours, then take out the mold directly, and use a press to pressurize to 100T to complete sintering. The sintered ingot was hot extruded at 450°C with an extrusion ratio of 16:1. The extruded round bar was annealed at 450°C for 8 hours to obtain the final profile. The microscopic transmission photos of the material are shown in figure 1 .

[0030] The high temperature (AlN+Al 2 o 3 ) / Al composite material was sampled at different locations, and the tensile strength at room temperature was 260-300MPa. The tensile strength at 375°C is 120-130MPa. After high-temperature annealing at 600°C for 12 hours, the strength at roo...

Embodiment 2

[0041] Select 1000g of spherical aluminum powder with an average particle size of 2.5 microns, cold isostatically press to a density of 85%, take out the ingot, place it in an air furnace at 350°C for heating and heat preservation for 10 hours, then raise the temperature to 580°C for 2 hours, and place it to cool to After room temperature, extrusion molding is carried out at 500°C, with an extrusion ratio of 9:1. The extruded strip was annealed at 450°C for 8 hours to obtain the final material.

[0042] The high temperature (AlN+Al 2 o 3 ) / Al composite material at room temperature tensile strength 280MPa. The tensile strength is 123MPa at 375°C. After 12h high-temperature annealing at 600°C, the strength of the composite material at room temperature can still reach 270MPa, and the tensile strength at 375°C can reach 116MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com