Heat radiation structure aggregate cell superimposed by multiple cell modules

A battery module and structure technology, used in secondary batteries, primary battery use/maintenance, circuits, etc., can solve the problems of narrow openings, difficult to dissipate heat, and cannot be directly exposed, and achieve the effect of convenient use and easy expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

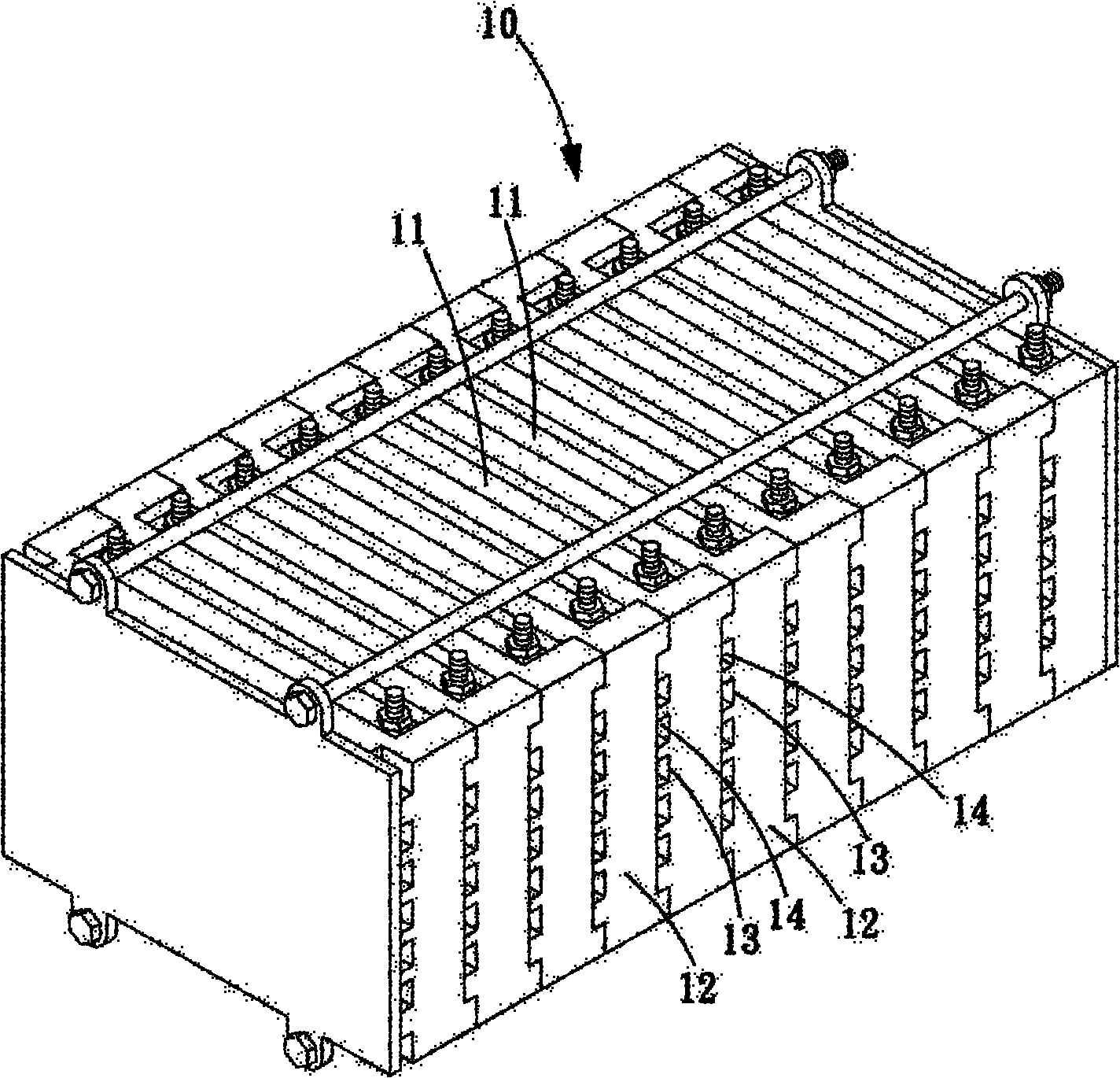

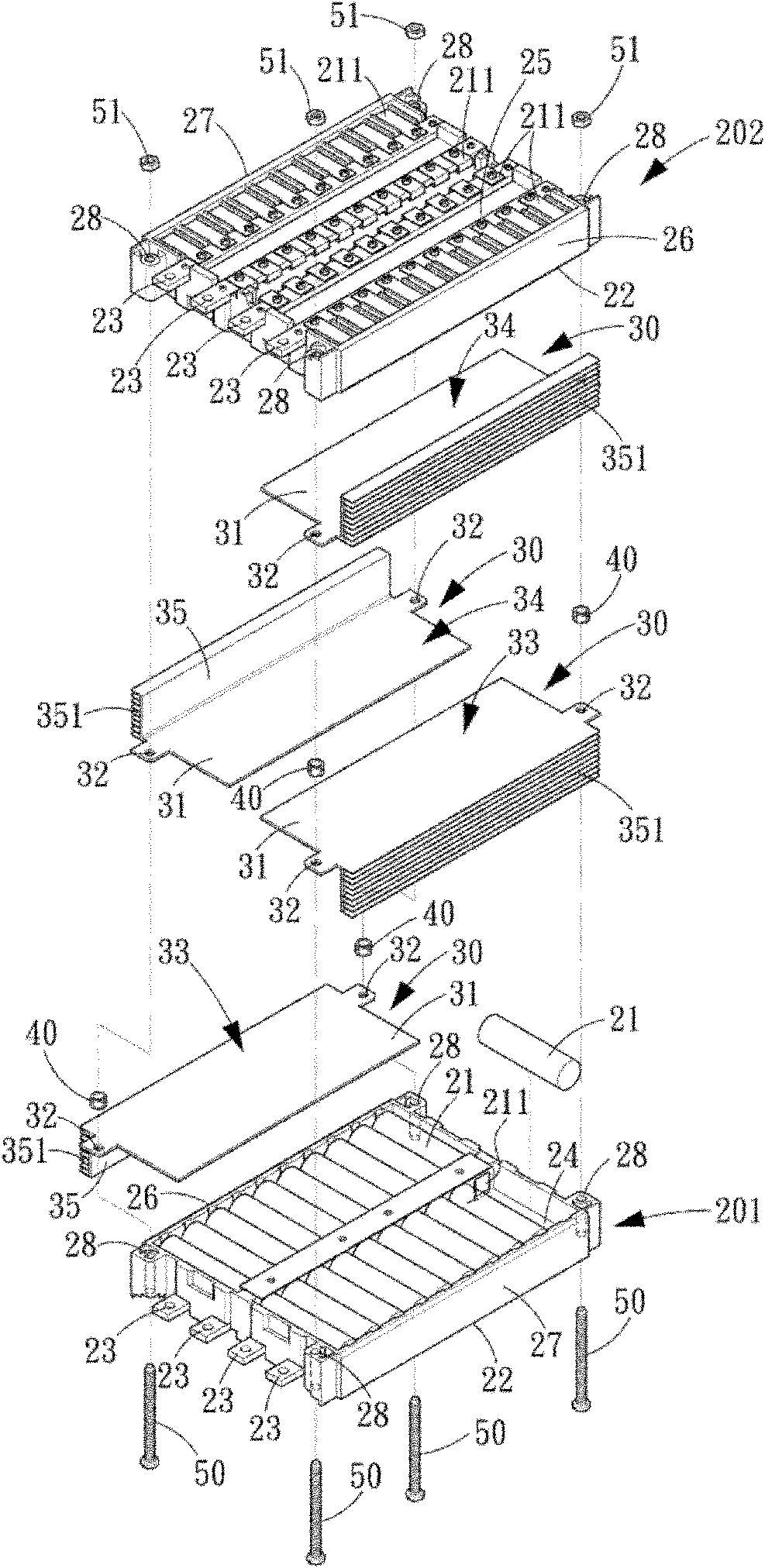

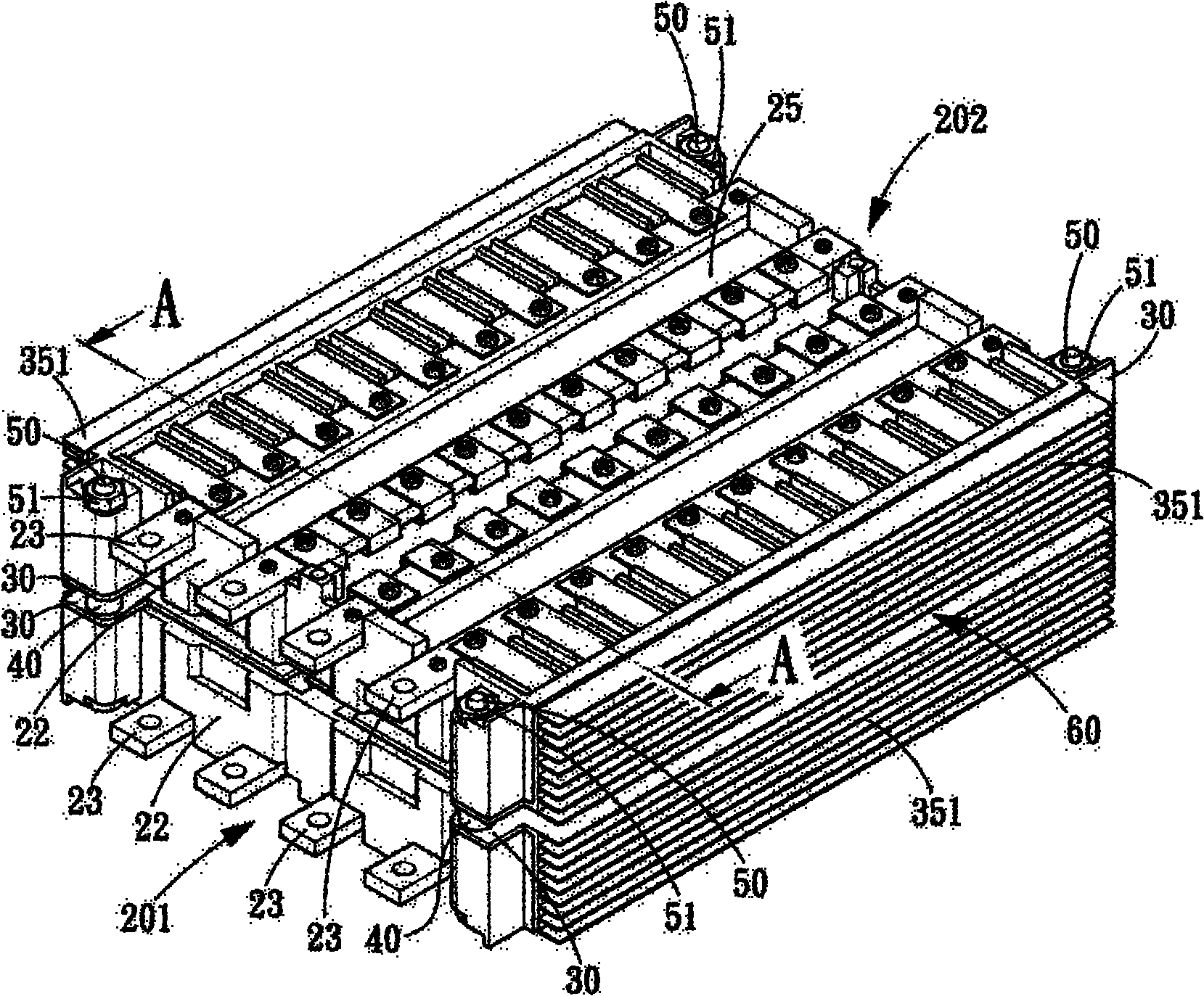

[0017] Such as Figure 2 to Figure 5 As shown, in the embodiment of the present invention, a plurality of battery modules are stacked to form a battery pack with a heat dissipation structure. The battery pack is mainly provided with four heat sinks 30 and four spacer sleeves between the two battery modules 201 and 202. 40, and then pass through the aforementioned components through four screw rods 50 to form a combination.

[0018] The battery modules 201, 202 are a plurality of individual batteries 21 electrically connected together through metal connecting pieces 211, and then installed in a rectangular frame 22. The individual batteries 21 have a common output terminal 23, as mentioned above Two corresponding faces of the frame 22 are defined as an inner face 24 and an outer face 25, and two corresponding sides of the frame 22 are defined as a left side 26 and a right side 27, and a side of each individual battery 21 is defined from the described The inner surface 24 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com