Slide fastener

A technology of zipper and zipper teeth, which is applied in the direction of sliding fastener components, applications, fasteners, etc., and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

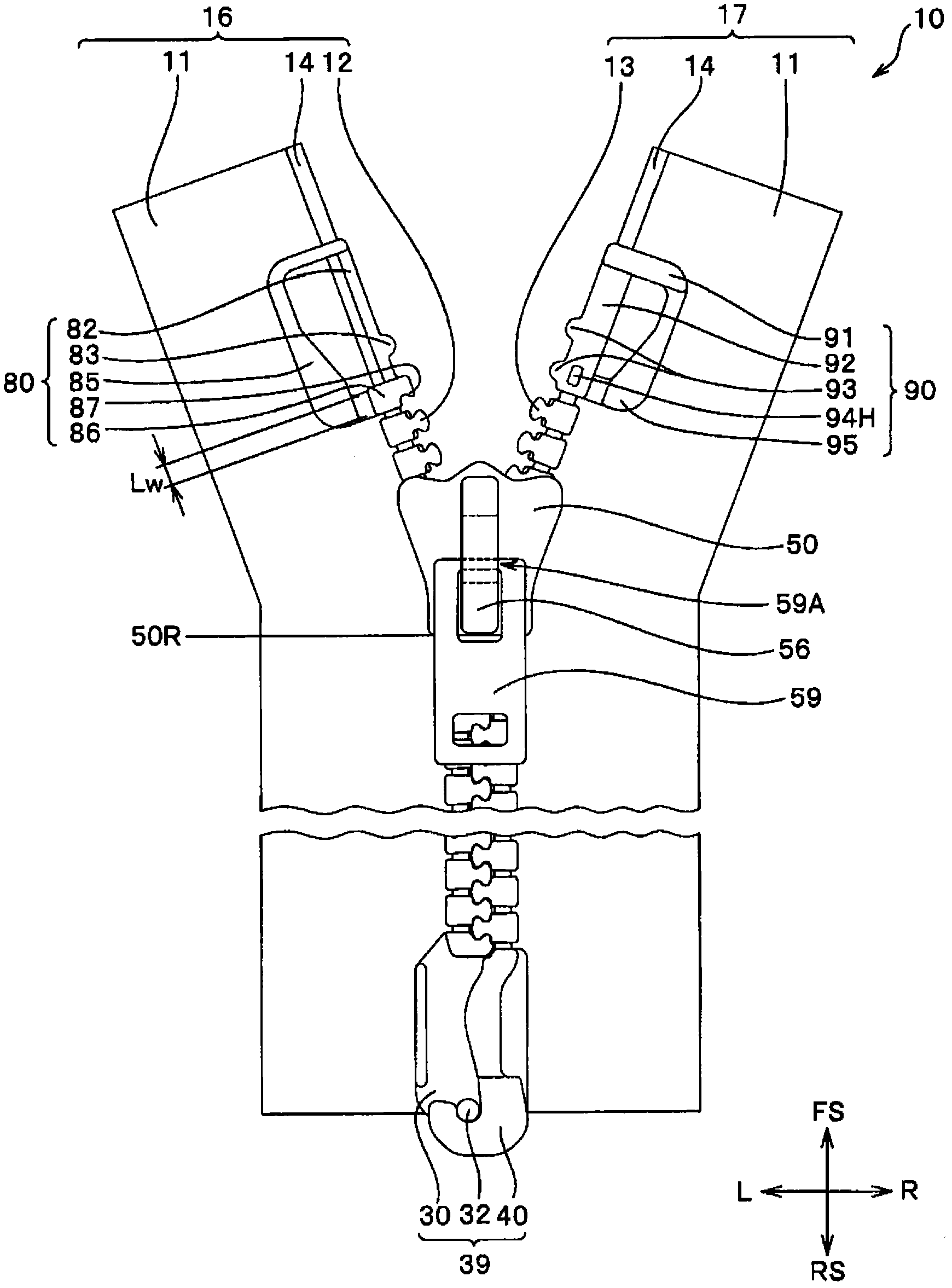

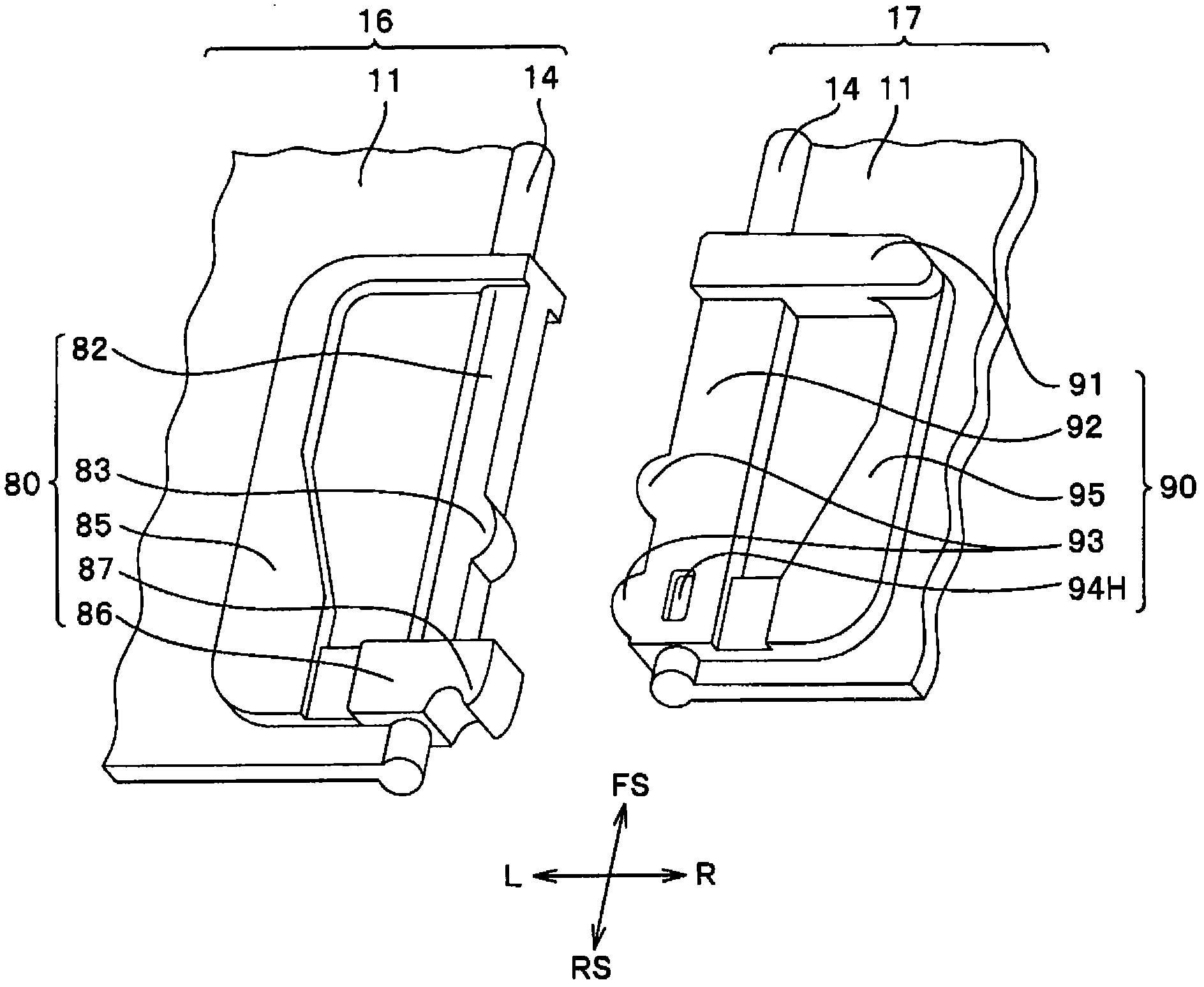

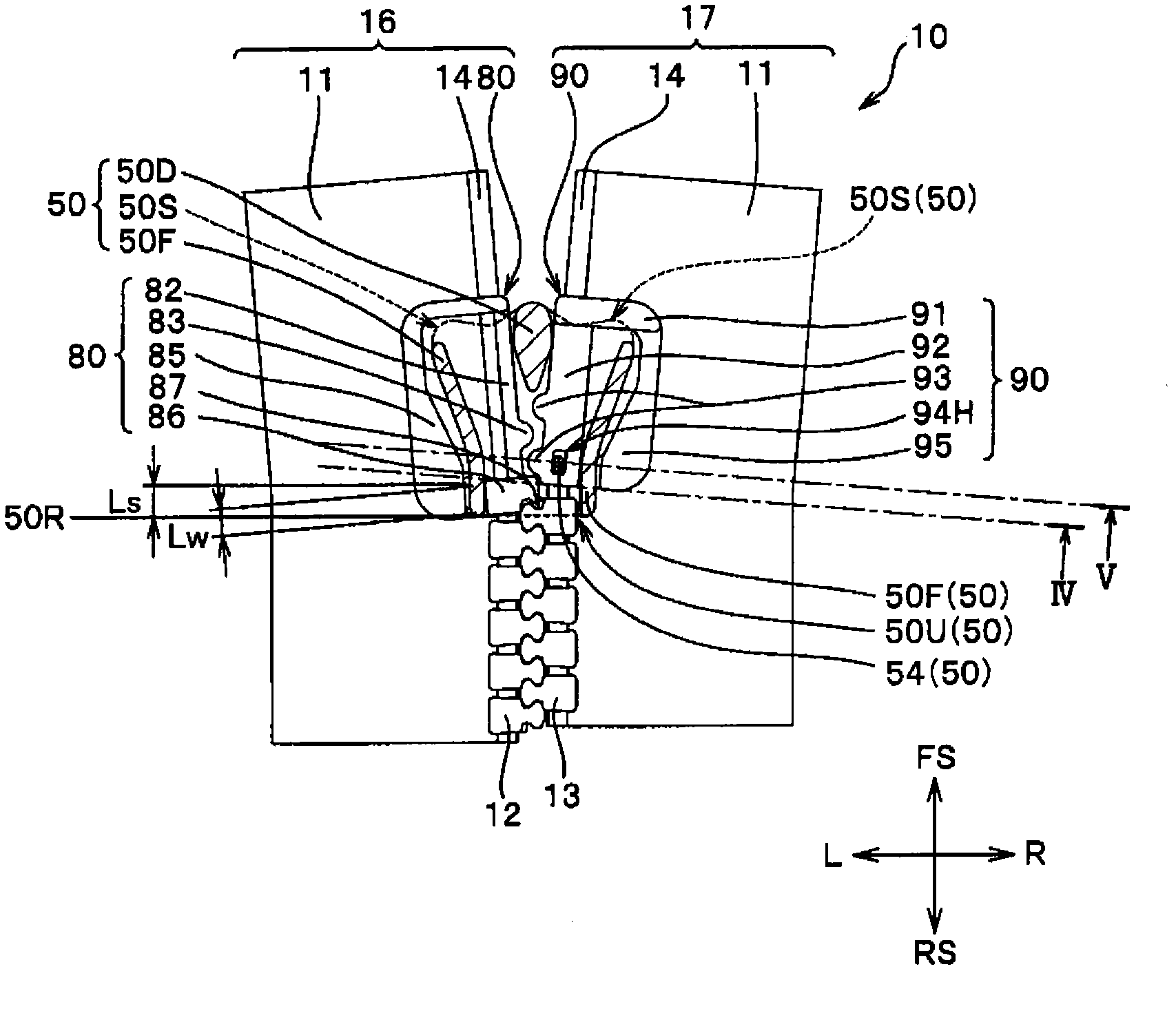

[0067] Below, while referring to the attached Figure 1 Typical examples of the slide fastener of the present invention will be specifically described. figure 1 It is a top view of the slide fastener 10 of this invention. figure 2 yes figure 1 The shown slide fastener 10 is a partially enlarged perspective view of the vicinity of the pull-out member 80 and the holding member 90 attached to the engaging slide end side of the first and second engaging elements 12 and 13 rows. image 3 In the state where the slide fastener 10 is closed by sliding the slider 50 to the engaging sliding end, the upper flap 52 of the slider 50 and the cut surface between the first and second zipper strings 16, 17 are closed. The slider 50 is cut and shows a top sectional view of the engaging element guide passage 50T. Figure 4 yes image 3 The sectional view shown in the direction of IV. Figure 5 yes image 3 The sectional view shown in the V direction.

[0068] Figure 1 to Figure 5 The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com