Method and apparatus for discharging liquid material, and program

A liquid material and discharge device technology, which is applied to the surface coating liquid device, spray device, spray device, etc., can solve the problems of particle generation, contamination of liquid material, deformation, etc., achieve stable discharge state, and improve discharge accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (Structure of discharge device)

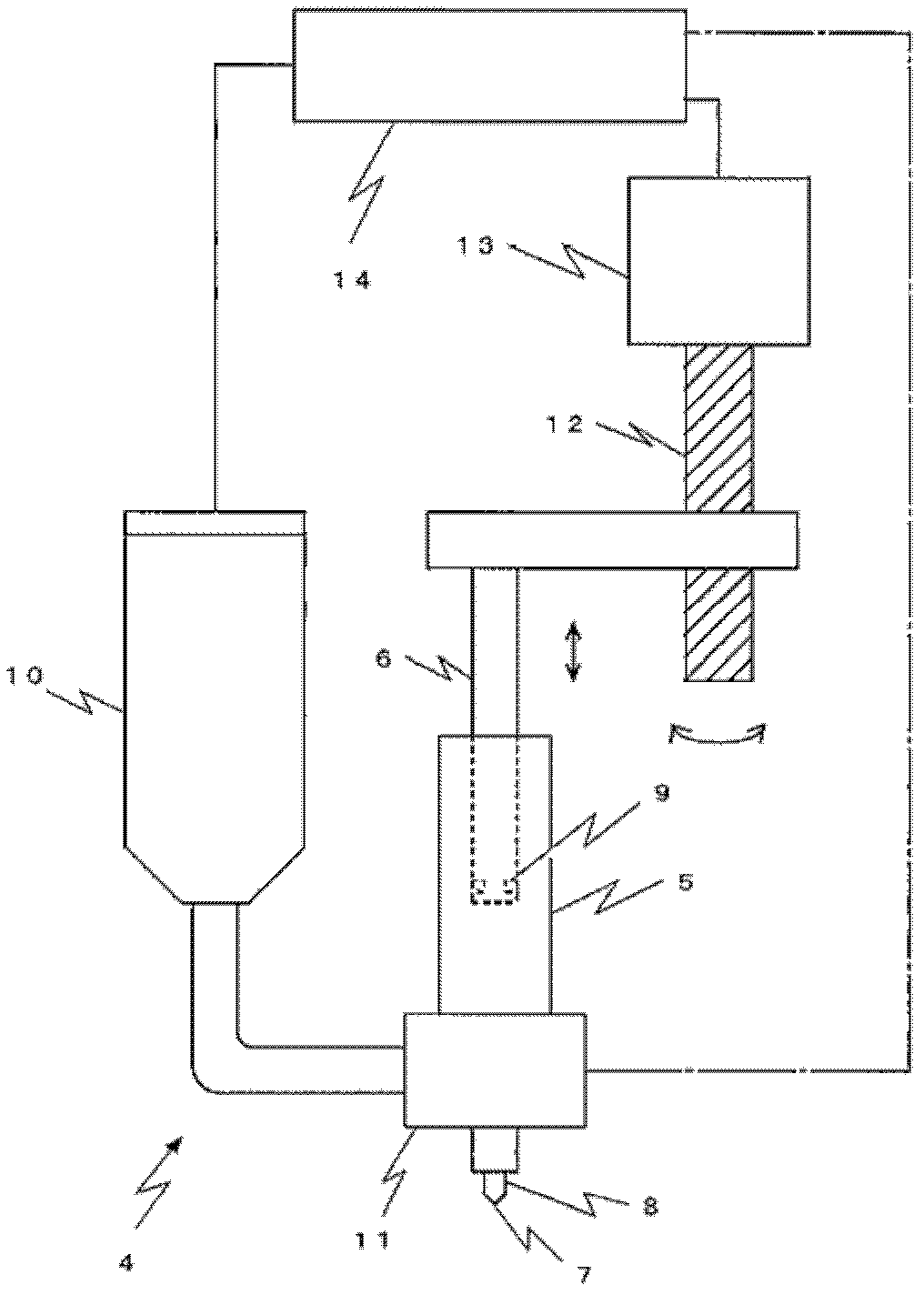

[0077] The discharge device of this embodiment refers to image 3 The following explanations are made. In addition, the liquid material used in this example is a liquid crystal (viscosity = about 20 mPa·s).

[0078] image 3 The shown discharge device 4 comprises: a tubular metering tube 5; a plunger 6 connected in the metering tube 5 with a sealing portion 9; a nozzle 8 having a discharge port 7; a storage container 10 for storing liquid materials; To switch the communication of the metering tube 5 and the nozzle 8 or to switch the communication of the storage container 10 and the metering tube 5; the motor 13 used to drive the screw shaft 12 to drive the plunger 6 as a driving source; and to control the switching valve 11 or the control device 14 of the action such as motor 13. In addition, in order to supply the liquid material smoothly, the storage container 10 is connected to a compressed gas source (not shown) via the control ...

Embodiment 2

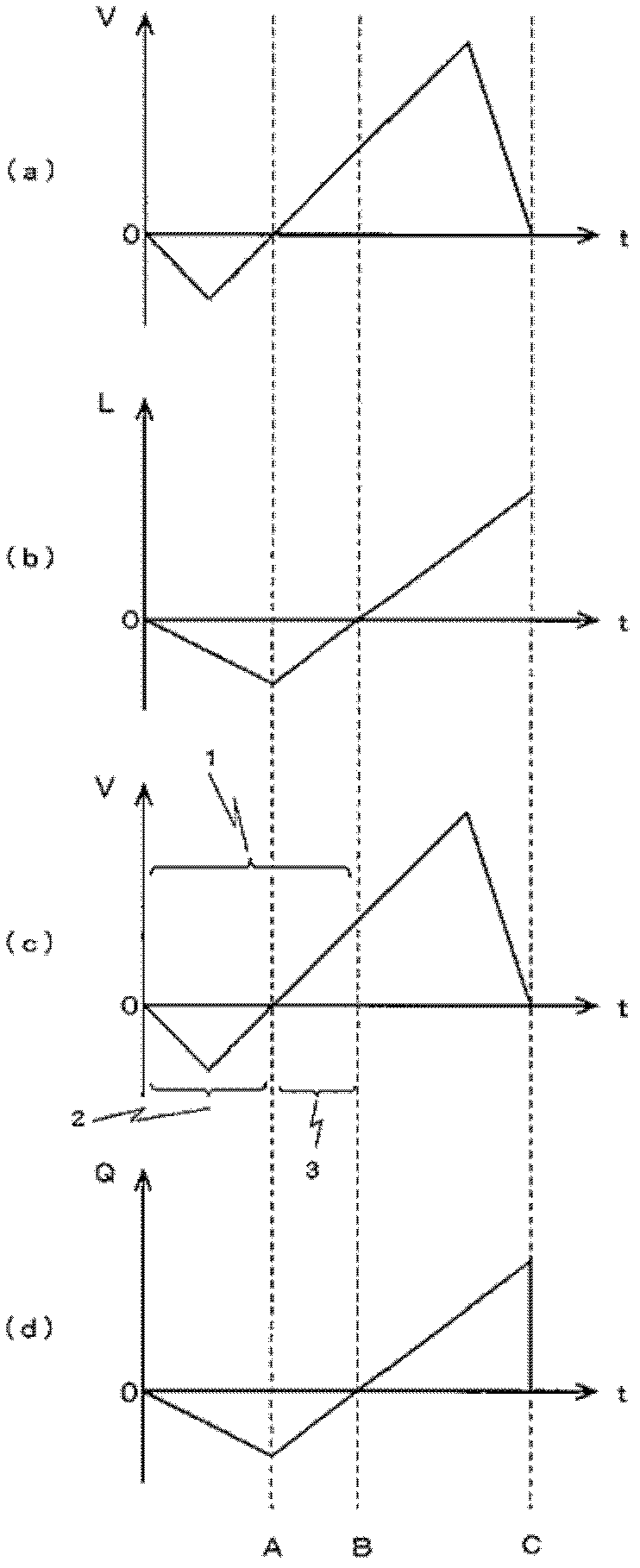

[0094] In the second embodiment, a method of discharging by combining different types of preparatory operations in the same discharge device as in the first embodiment will be described. Figures 5 to 9 Indicates the change in plunger speed with time.

[0095] (1) The method of performing preparatory action each time during continuous discharge [ Figure 5 ]

[0096]When the liquid material in the metering part is continuously discharged after filling the metering part once, and the liquid material in the metering part is discharged multiple times, when the discharge interval becomes longer or the discharge accuracy is important, such as Figure 5 As shown, preparatory action 1 is performed at the beginning of each discharge action. In this way, the accuracy of each ejection can be improved, and the variation between each ejection can be reduced.

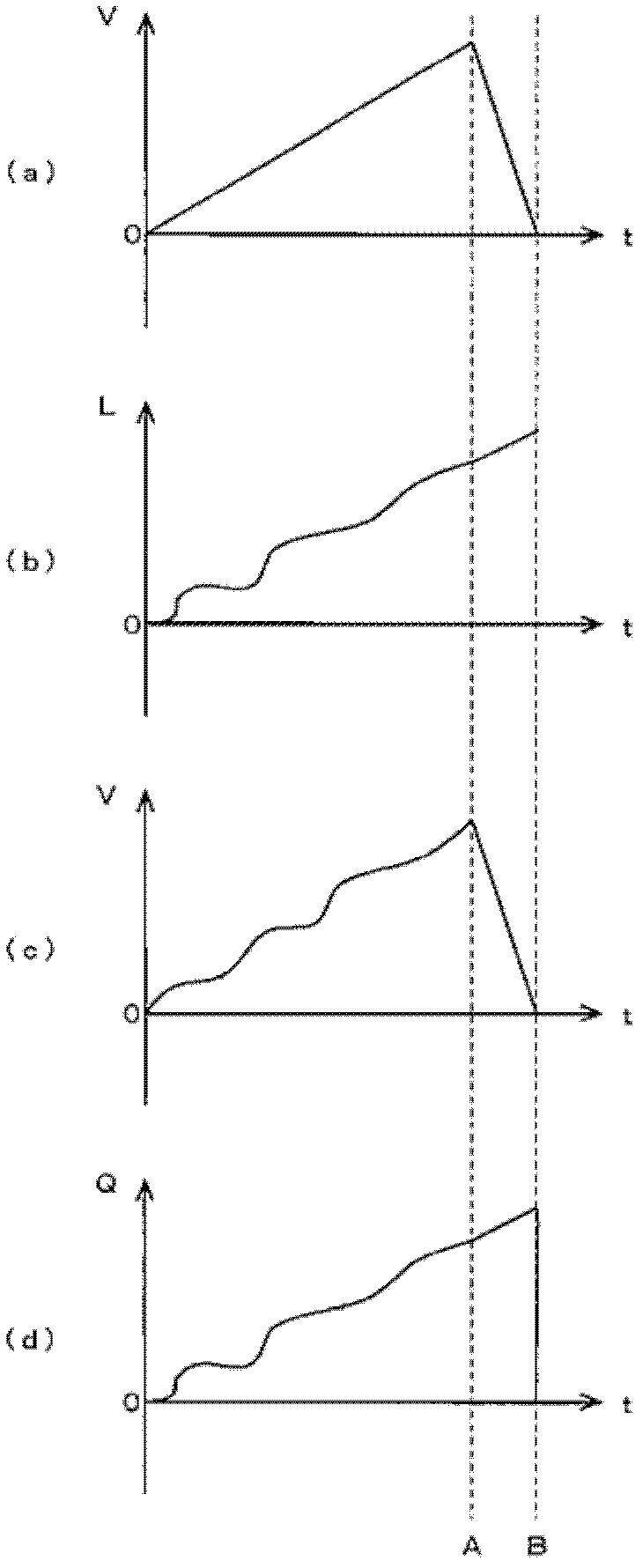

[0097] (2) Method of setting small reciprocating motion as preparatory motion [ Image 6 ]

[0098] The plunger 6 normally st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com