Substrate processing apparatus and substrate processing method

A substrate processing device and substrate technology, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of hindering the discharge of the treatment liquid, hinder the flow of the treatment liquid, etc., and achieve the effect of improving uniformity and stable discharge state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058]

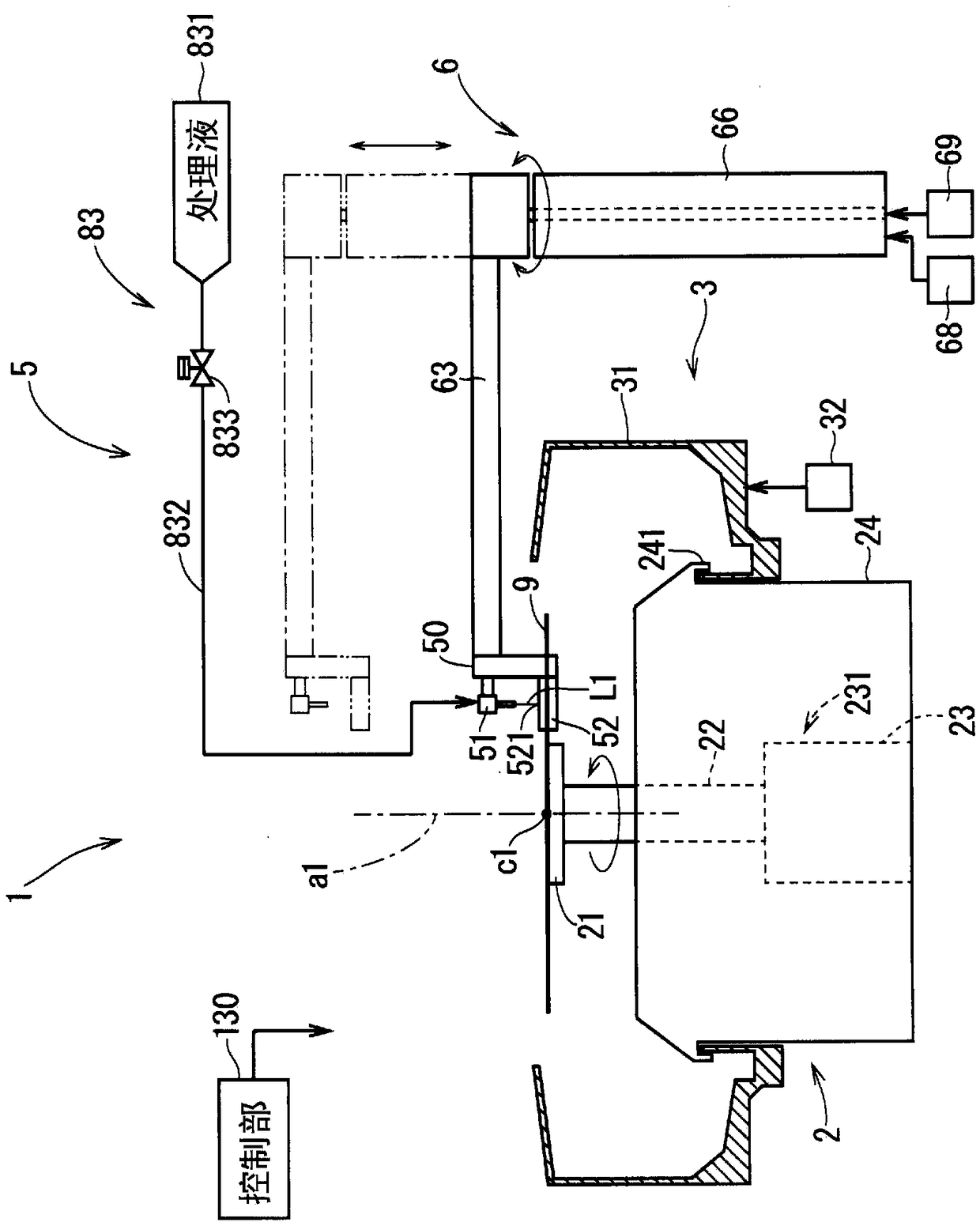

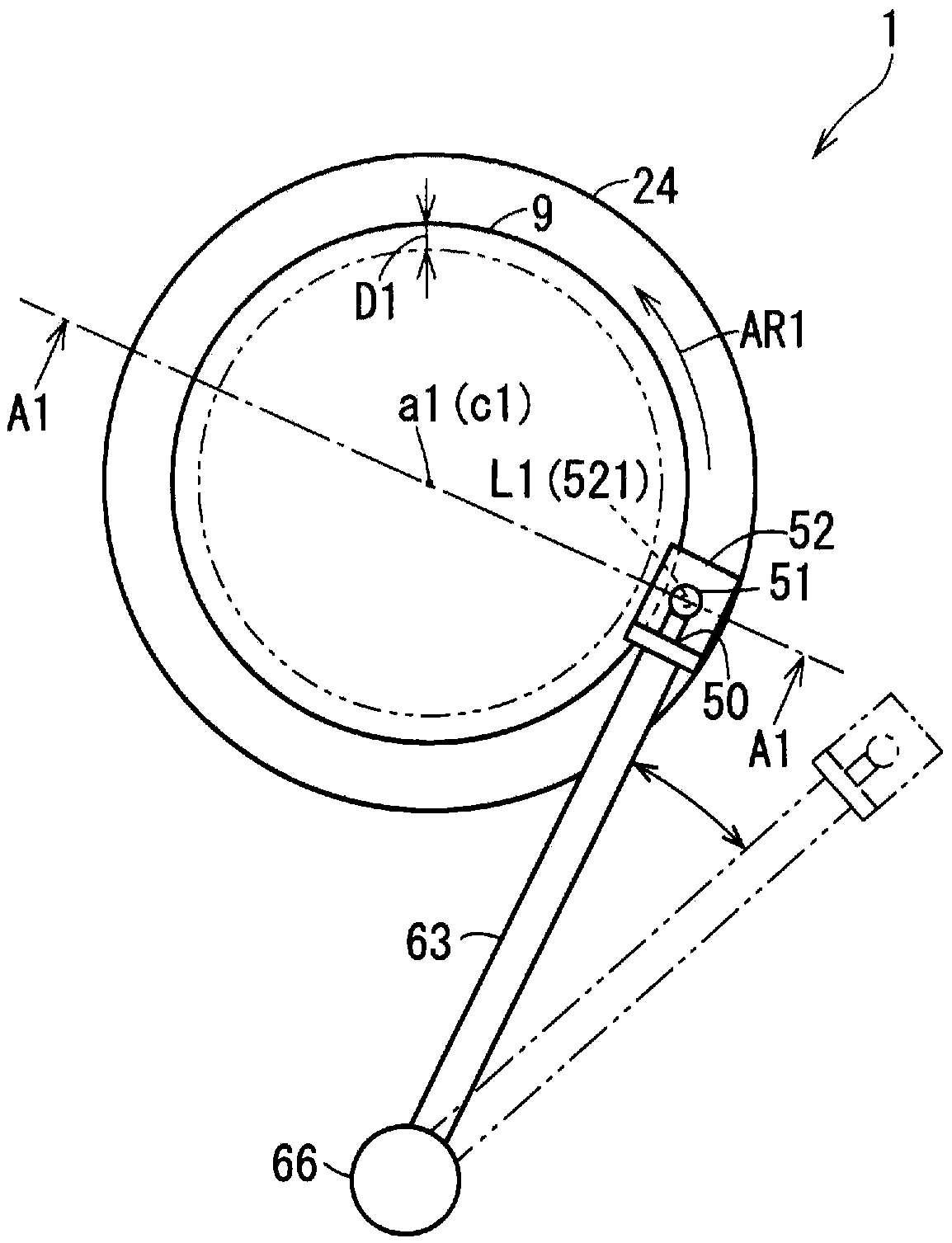

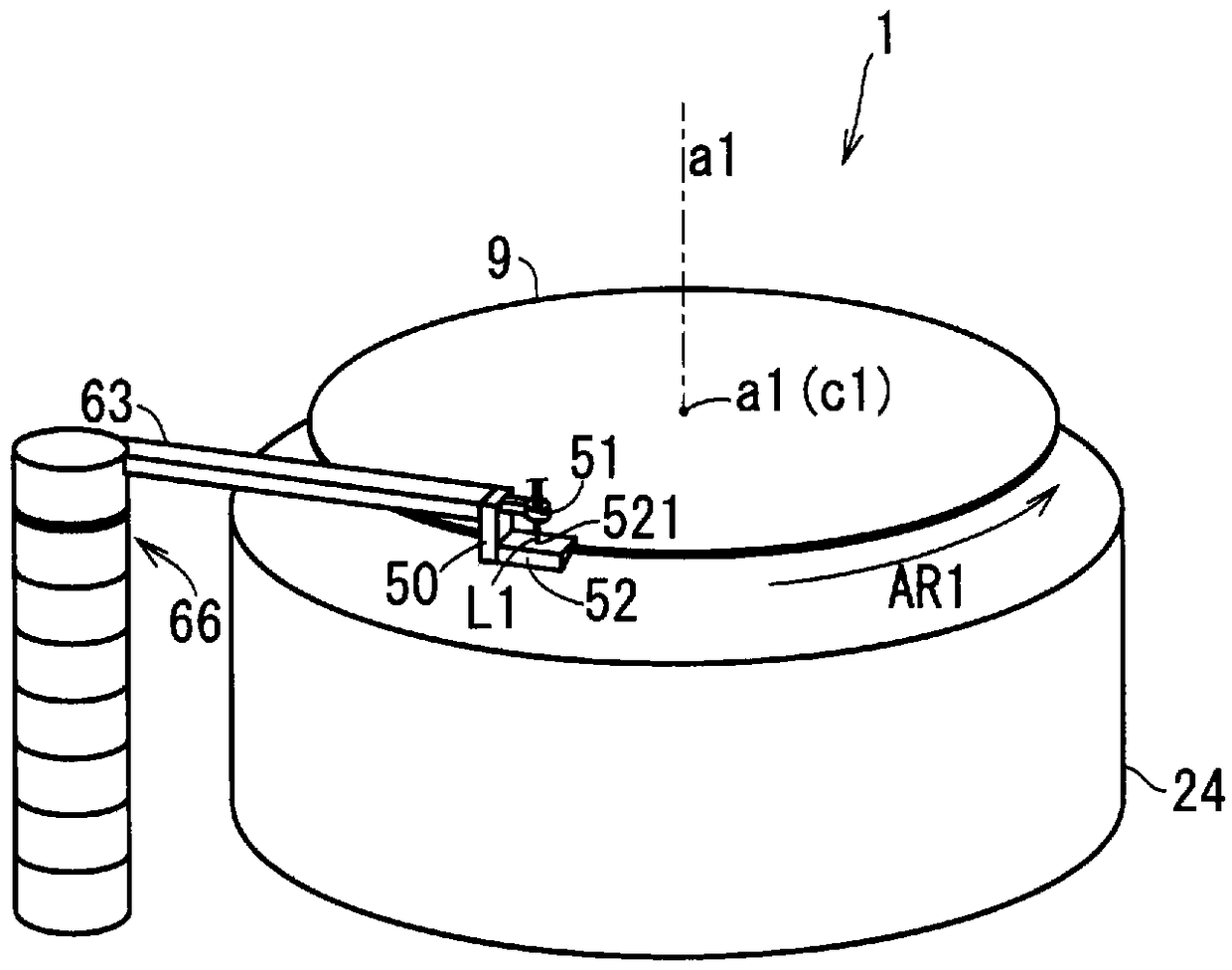

[0059] refer to Figure 1 ~ Figure 3 The configuration of the substrate processing apparatus 1 will be described. Figure 1 ~ Figure 3 It is a diagram for explaining the structure of the substrate processing apparatus 1 according to the embodiment. figure 1 , figure 2 It is a schematic side view and a schematic top view of the substrate processing apparatus 1 . image 3 It is a schematic perspective view of the substrate processing apparatus 1 viewed obliquely from above.

[0060] exist Figure 1 ~ Figure 3 In the figure, the substrate 9 is rotated in a predetermined rotation direction (direction of arrow AR1) around the rotation axis a1 by the spin chuck 21 in the state where the nozzle 51 and other members 52 are arranged at the respective processing positions. state. In addition, in figure 2 In the figure, the nozzle 51, other members 52, and the like arranged at the retracted position are shown by dotted lines. exist figure 2 , image 3 In , the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com