Inkjet printhead assembly having backside electrical connection

An inkjet print head, print head technology, applied in printing, inking device, etc., can solve the problems of printing maintenance and harmful printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Supply ink to the printhead integrated circuit (IC)

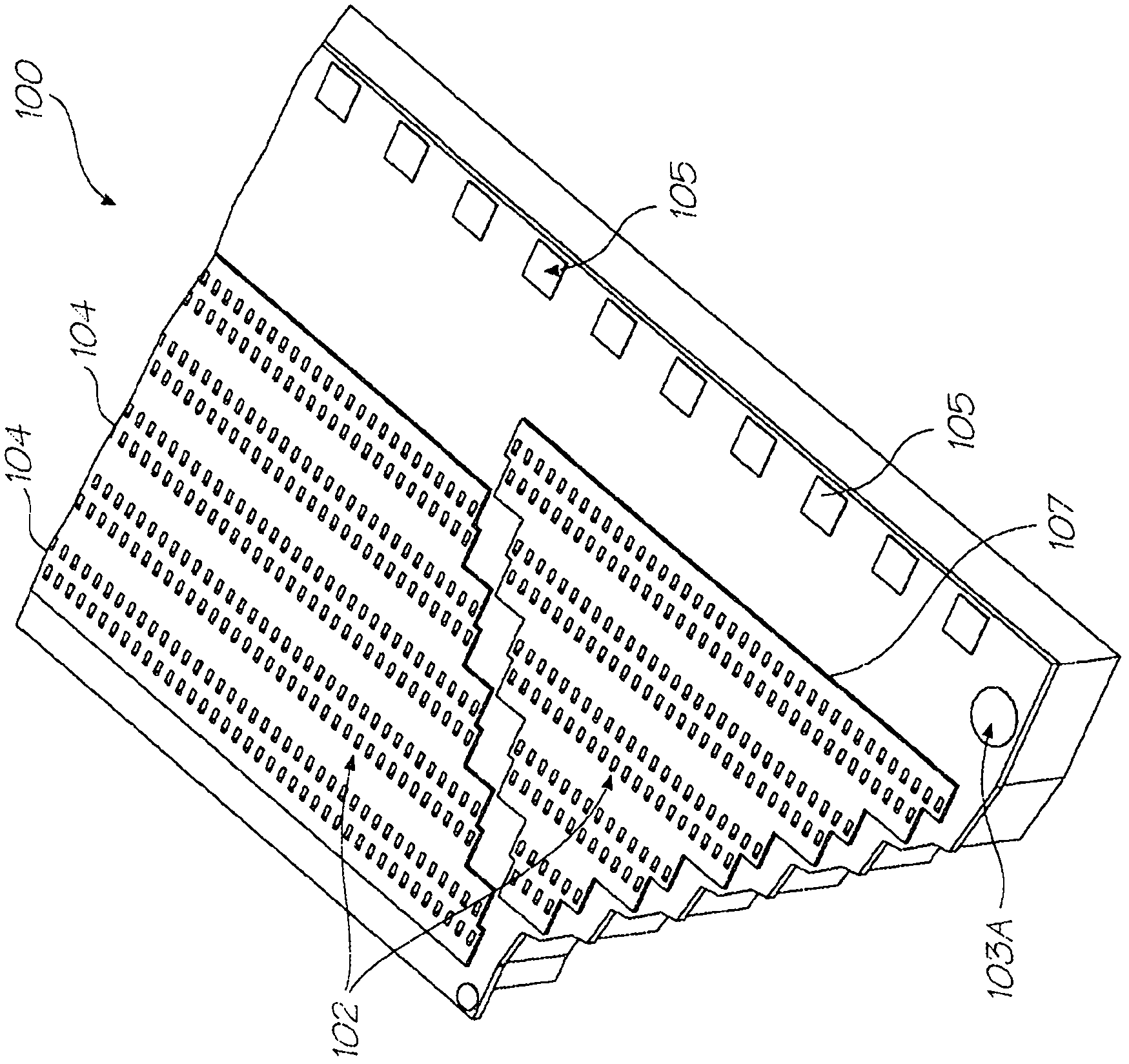

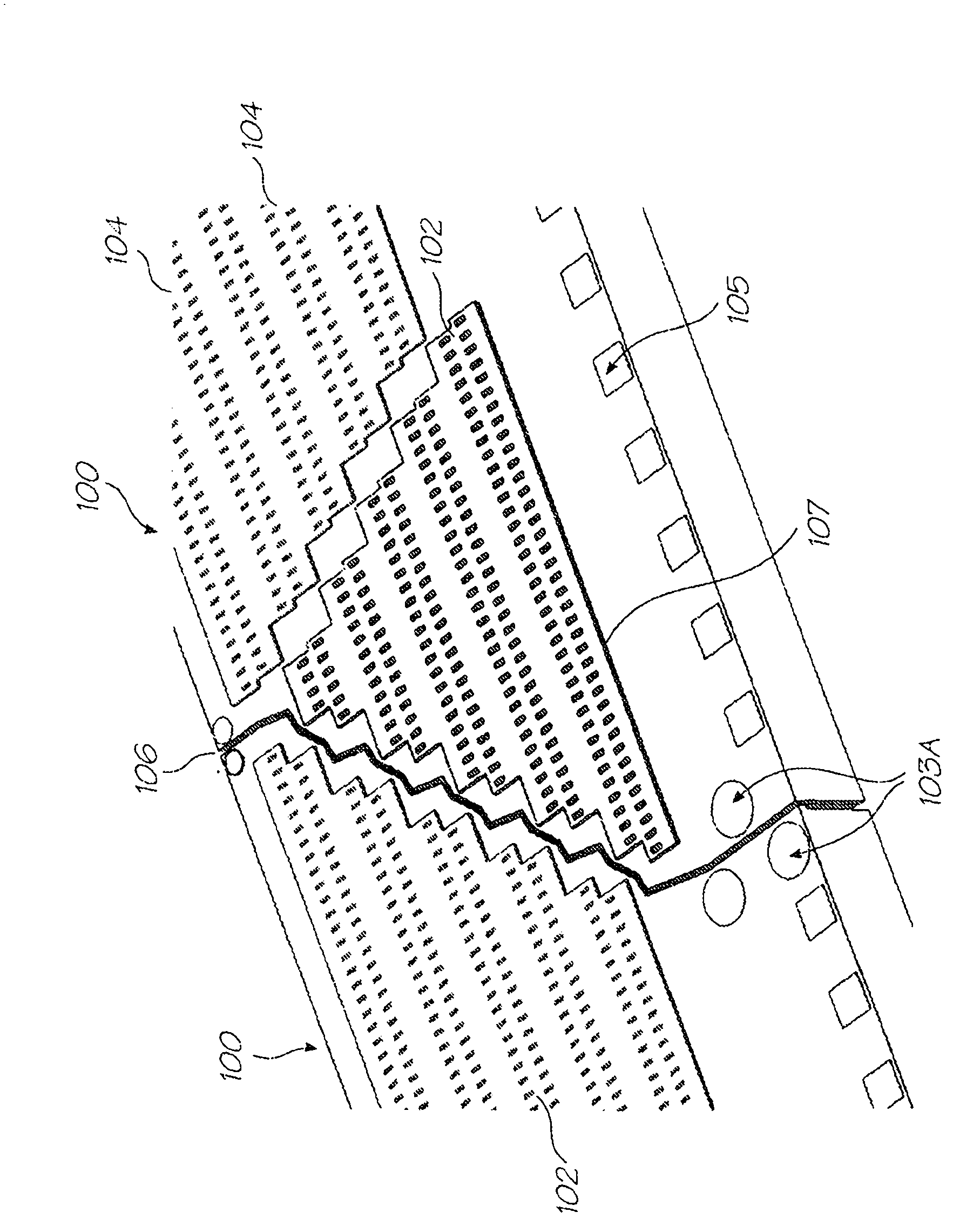

[0110] Applicants have thus far described printhead integrated circuits (or "chips") 100 that can be joined together in an end-to-end adjoining arrangement to define a pagewidth printhead. figure 1 The front side of a part of the printhead IC 100 is shown in a perspective view, while figure 2 A pair of printhead ICs are shown adjoining each other.

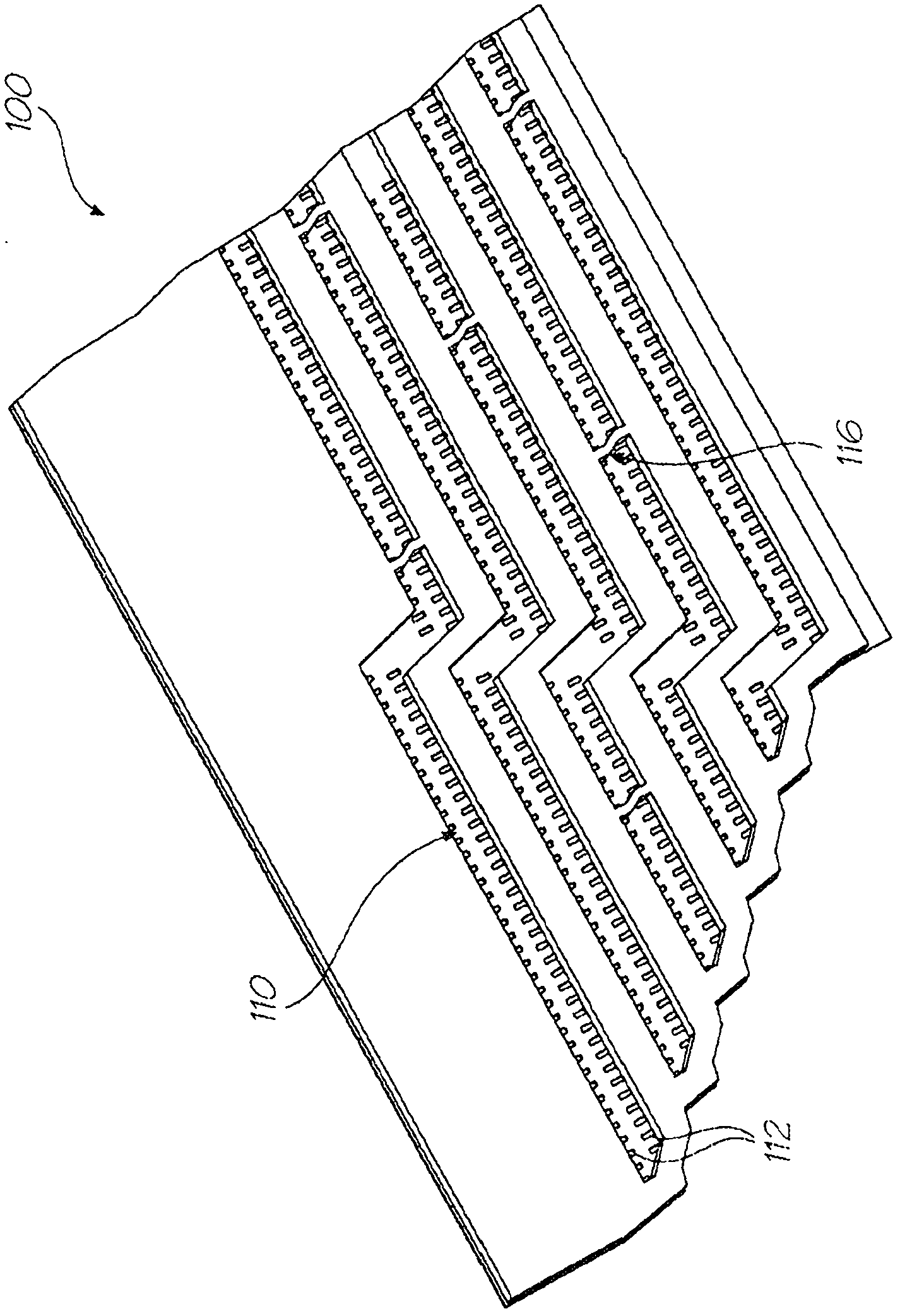

[0111] Each printhead IC 100 includes thousands of nozzles 102 arranged in a row. Such as figure 1 and 2 As shown in , the printhead IC 100 is configured to receive and print five different colors of ink (eg, CMYK and IR (infrared); CCMMY; or CMYKK). Each color channel 104 of printhead IC 100 includes pairs of nozzle rows, one row of the pair printing even dots and the other row of the pair printing odd dots. Nozzles from each color channel 104 are vertically aligned in the paper feed direction to perform high resolution (eg, 1600 dpi) dot-to-dot printing. The hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com